MWW-structure molecular sieve and preparation method thereof

A molecular sieve and desorption technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of molecular sieve framework damage, poor controllability of desiliconization, etc., and achieve the effect of crystal particle dispersion and increased disorder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Preparation method provided by the invention, R1 / SiO in said mixture 2 =0.05~0.5, R2 / SiO 2 =0~0.5, namely R2 / SiO 2 When the endpoint value of the range of is zero, it means that the nitrogen-containing organic base R1 can be used alone. The method of using nitrogen-containing organic base R1 alone is especially suitable for the case where the raw material MWW molecular sieve has complete crystallization, for example, the relative crystallinity of the raw material MWW structure molecular sieve is generally required to be ≥ 100%. This method can achieve a significant increase in the specific surface area, pore volume and 2,4,6-collidine adsorption of the MWW structure molecular sieve product sample under the premise of a slight decrease in crystallinity.

[0037] In the preparation method provided by the present invention, the simultaneous treatment of nitrogen-containing organic base R1 and organic amine R2 is especially suitable for MWW structure molecular sieves with...

Embodiment 1

[0052] This example illustrates the molecular sieve provided by the present invention and its preparation method.

[0053] In the above comparative example 1, the MCM-22 sample without roasting and containing hexamethyleneimine is MCM-22P molecular sieve, and the MCM-22 sample that has been roasted and has removed hexamethyleneimine is MCM-22C molecular sieve .

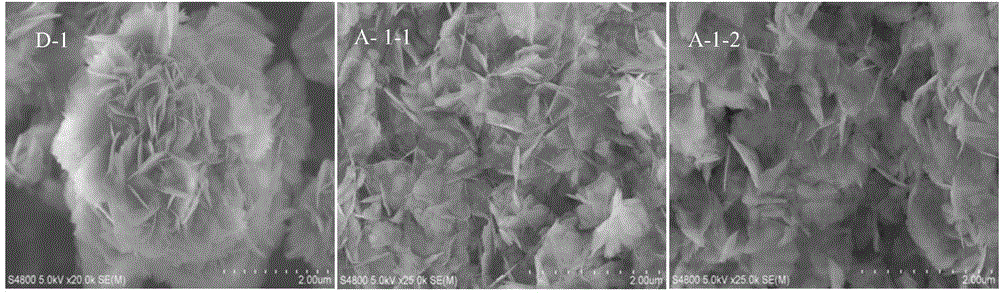

[0054] Add tetraethylammonium hydroxide solution (TEAOH, 25wt.%) into deionized water, then add MCM-22P or MCM-22C molecular sieves to the above solution, continue to stir evenly, and the colloidal molar ratio of the obtained mixture is SiO 2 :0.1TEAOH:15H 2O. The colloid of the obtained mixture was transferred to a closed crystallization kettle, and the crystallization temperature was 150°C for dynamic crystallization for 16 hours. After cooling, the product was taken out. After filtering, washing, drying and roasting, the treated molecular sieve powder, MCM-22P was obtained. The number of the corresponding proces...

Embodiment 2

[0068] This example illustrates the molecular sieve provided by the present invention and its preparation method.

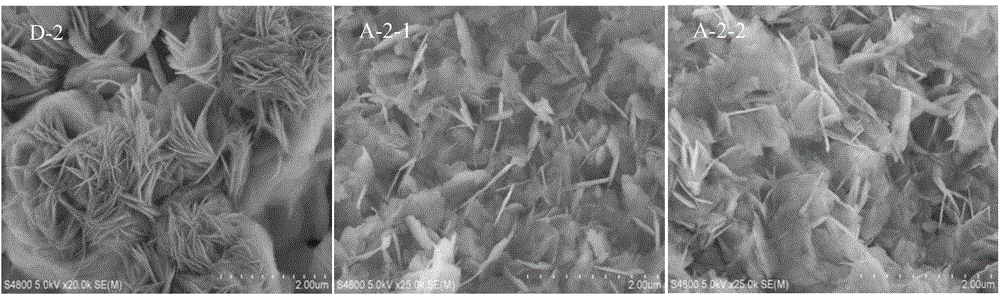

[0069] Tetraethylammonium hydroxide solution (25wt.%) was added to deionized water, and then MCM-49 containing hexamethyleneimine without roasting in Comparative Example 2 was added to the above solution and continued to stir evenly. The colloidal molar ratio of the resulting mixture is SiO 2 :0.1TEAOH:15H 2 O. Then, the obtained mixture was transferred to a closed crystallization kettle, the crystallization temperature was 150°C, and the dynamic crystallization was performed for 16 hours. After cooling, the product was taken out. After filtering, washing, drying and roasting, the modified molecular sieve raw powder was obtained. Sample No. for A-2-1.

[0070] The same as above, the difference is that the MCM-49 containing hexamethyleneimine that has not been roasted in Comparative Example 2 is replaced by the MCM-49 that has been roasted and has removed hexam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com