Linear motor permanent magnetic brake

A technology of linear motors and brakes, applied in the direction of permanent magnet clutches/brakes, electric components, electrical components, etc., can solve the problems of non-linear locking, low mechanical reliability, long braking time, etc., and achieves simple operation and excellent structure Compact and easy to process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

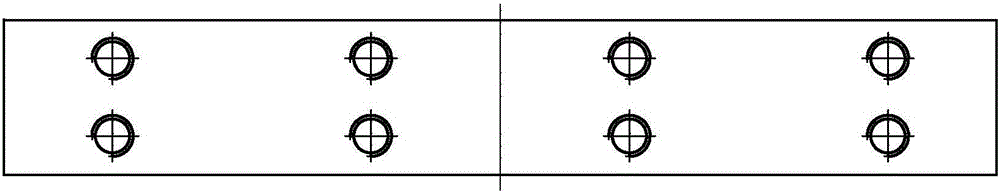

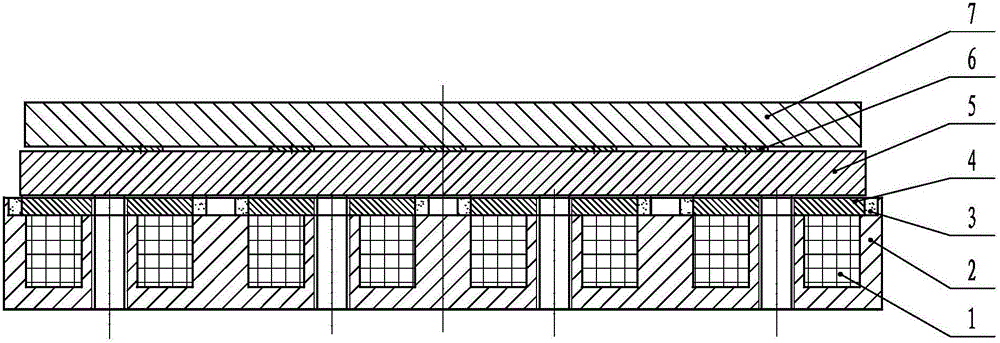

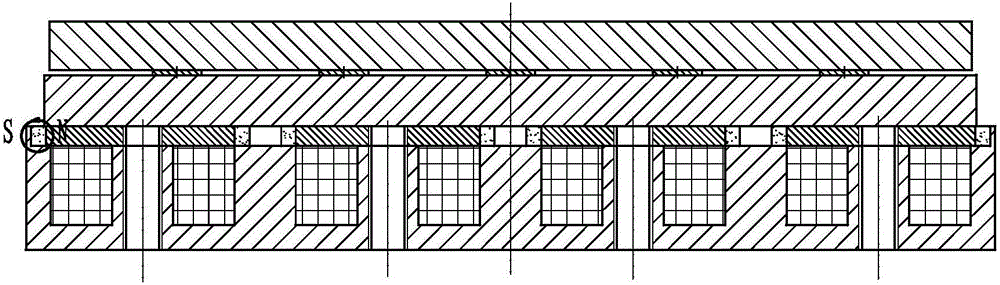

[0021] Such as figure 1 and 2 As shown, the linear motor brake of the present invention is mainly divided into two parts, which are respectively a static iron core assembly and a moving plate assembly. The static iron core assembly includes a coil 1, a static iron core 2, a yoke 4 and a magnetic steel 3; Plate 5, fixed plate 7 and leaf spring 6. The static iron core component is fixed to the secondary of the linear motor, and the moving plate component is fixed to the primary of the linear motor. After the brake is powered off, the coil cannot generate a magnetic field, and the magnetic steel magnetic field circuit indirectly connects the primary and secondary of the linear motor through the suction of the moving plate, that is, the motor is in the brake state and cannot run. After the brake is powered on, the coil generates a magnetic field, and the coil magnetic field circuit short-circuits the magnetic steel magnetic field circuit, and the magnetic steel magnetic field ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com