Ultrasonic cavitation and hydrofracture combined stimulation coalbed methane extraction method

A hydraulic fracturing and ultrasonic technology, applied in the fields of mining fluids, mining equipment, earthwork drilling, etc., can solve problems such as failure to achieve anti-penetration effect, and achieve good fracturing effect, long propagation distance, and wide practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

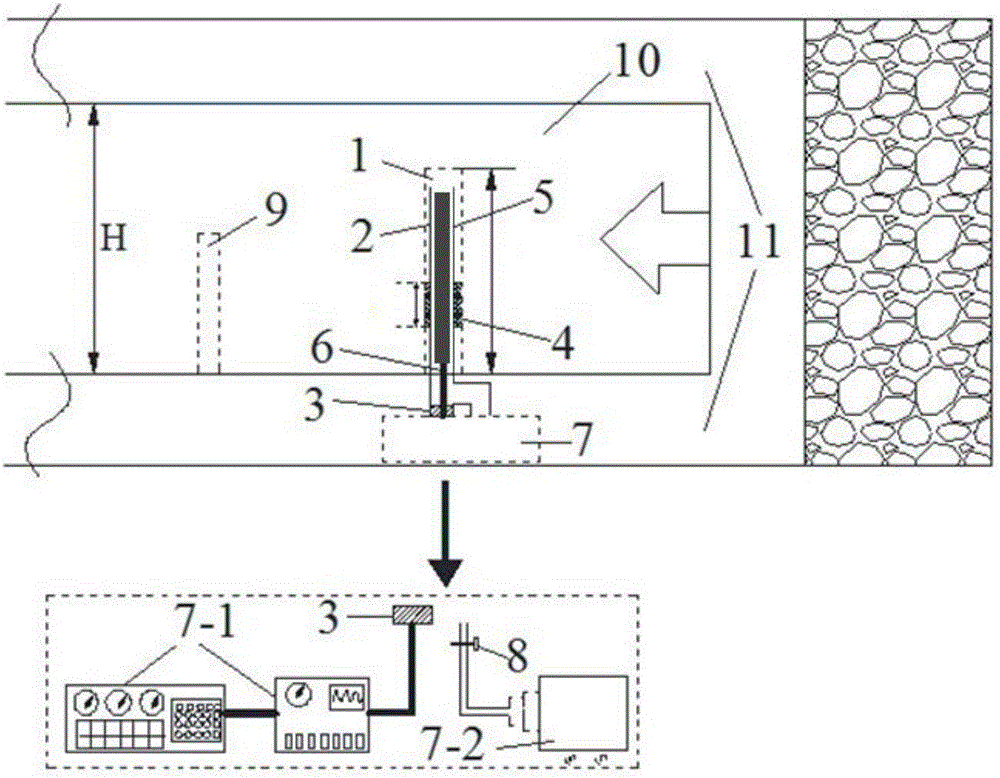

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

[0030] as attached figure 1 and 4 As shown in Fig. 1, the anti-permeability fracturing units are implemented sequentially in groups along the bedding direction of the coal seam in the coal seam roadway.

[0031] a. First construct a main borehole with a diameter of 110-150mm, the hole length h is 0.75-0.8 of the width H of the anti-reflection mining coal seam, and the distance from the main borehole is 20-25m, and the horizontal length of the construction is 0.7-0.8H , a monitoring borehole 9 with an aperture of 80-110mm;

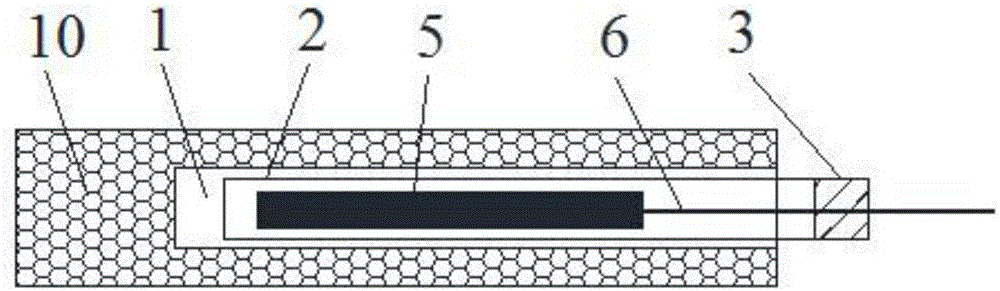

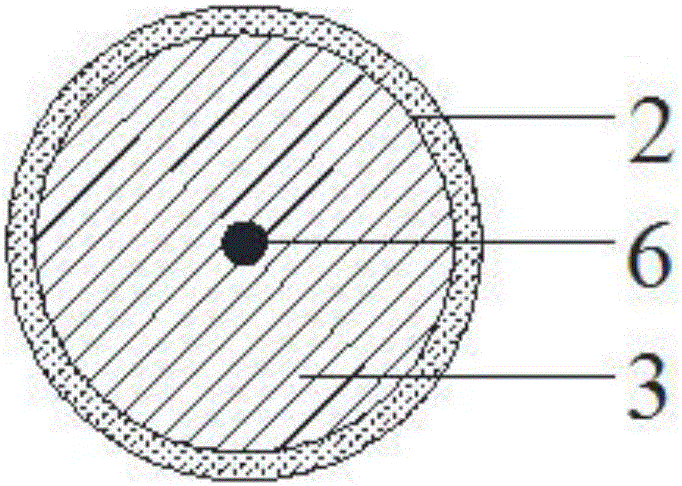

[0032] b. After the drilling construction is completed, the h-shaped pressure-resistant steel pipe 2 containing the cylindrical ultrasonic transducer 5 is sent into the main borehole 1. The distance between the front end of the h-shaped pressure-resistant steel pipe 2 and the front end of the main borehole 1 is 2~ 5m, the outer diameter of the ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com