Method for rapidly replacing adhesive tape

A tape and fast technology, applied in the field of belt replacement for mines, can solve the problems of low belt efficiency, complex process, time-consuming and labor-consuming, etc., achieve high utilization rate, simplify construction process, and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

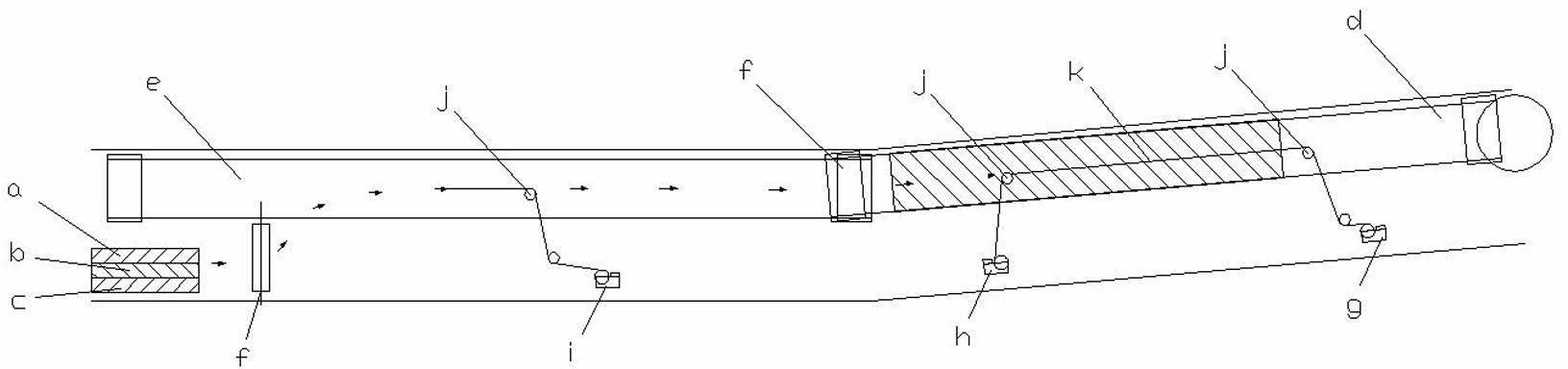

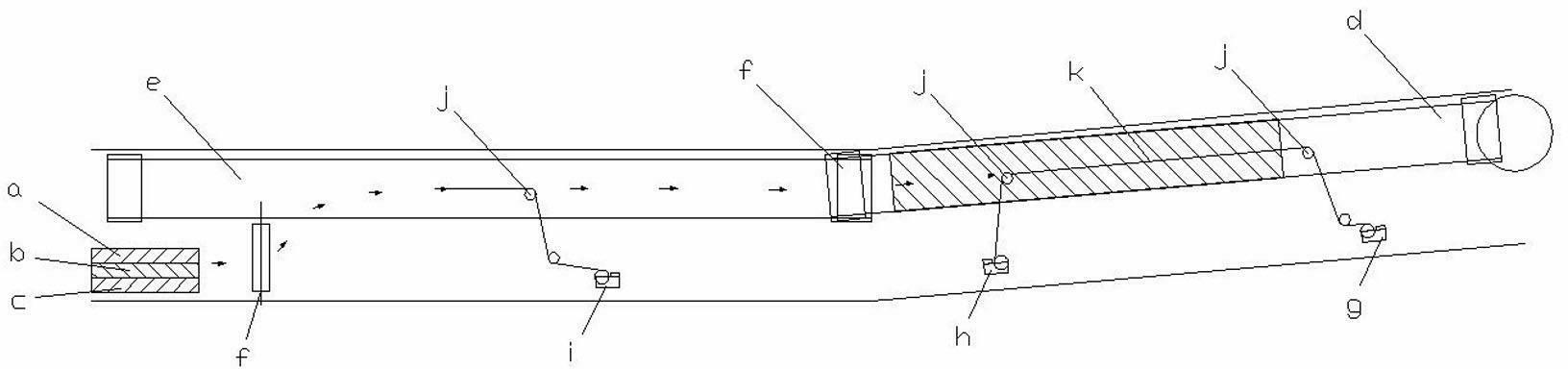

[0020] A method for quickly changing the tape, specifically for changing the belt of the conveyor Id, comprising the following steps,

[0021] (1) Preparatory work before replacement, including vulcanizing and connecting all new tapes into three sections of tape Ia, tape IIb, and tape IIIc, in which the length of tape Ia is the same as that of tape IIb and greater than that of tape IIIc, and all new tapes According to the sequence of tape Ⅰa, tape Ⅱb, and tape Ⅲc, all of them are neatly stacked on the track at the tail of conveyor Ⅱe behind conveyor Ⅰd from top to bottom; a roller f is set up at the head and tail of conveyor Ⅱe; Fix the column return vehicle Ig and column return vehicle IIh on the ground at both ends of the machine Id, fix the column return vehicle IIIi in the middle of the conveyor IIe, and tape on the side of the column return vehicle Ig, column return vehicle IIh and column return vehicle IIIi There are pulley block devices j on the top, and a traction wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com