Building door and window mounting rigid foamed polyurethane filling construction process

A technology for foaming polyurethane, building doors and windows, applied in the direction of frame fixing, etc., can solve the problems of mold, cracking of the mortar layer and the stucco layer of the window cover, and moisture on the inner wall.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

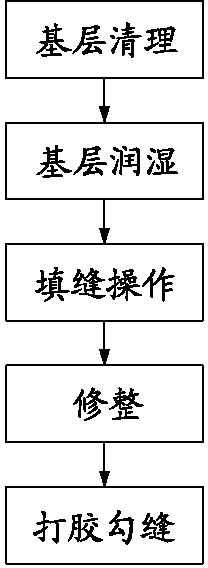

[0027] What the present invention discloses is a kind of building door and window installation rigid foam polyurethane plug filling construction technology, such as figure 1 , 2 Shown, be preferred embodiment of the present invention, comprise following flow process:

[0028] (1) Base-level cleaning: Use a hard-bristled brush to clean the base-level surface.

[0029] (2) Wetting of the base layer: Spray a layer of clear water on the base layer, and it is required to spray evenly to form water mist, so that the PU polyurethane foaming agent filler can be fully bonded with the surrounding.

[0030] (3) Filling operation: use gun-type polyurethane foaming filler, shake the material in the tank fully for 1 minute and then install the gun. When using, turn the material tank upside down and connect the spray gun with threads, rotate and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com