Chaplet

A core support and core column technology, applied in the direction of mold box, casting molding equipment, metal processing equipment, etc., can solve the problems of increasing the difficulty of production organization, poor fusion performance, difficult operation, etc., to improve interchangeability and use efficiency, The effect of good leak-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

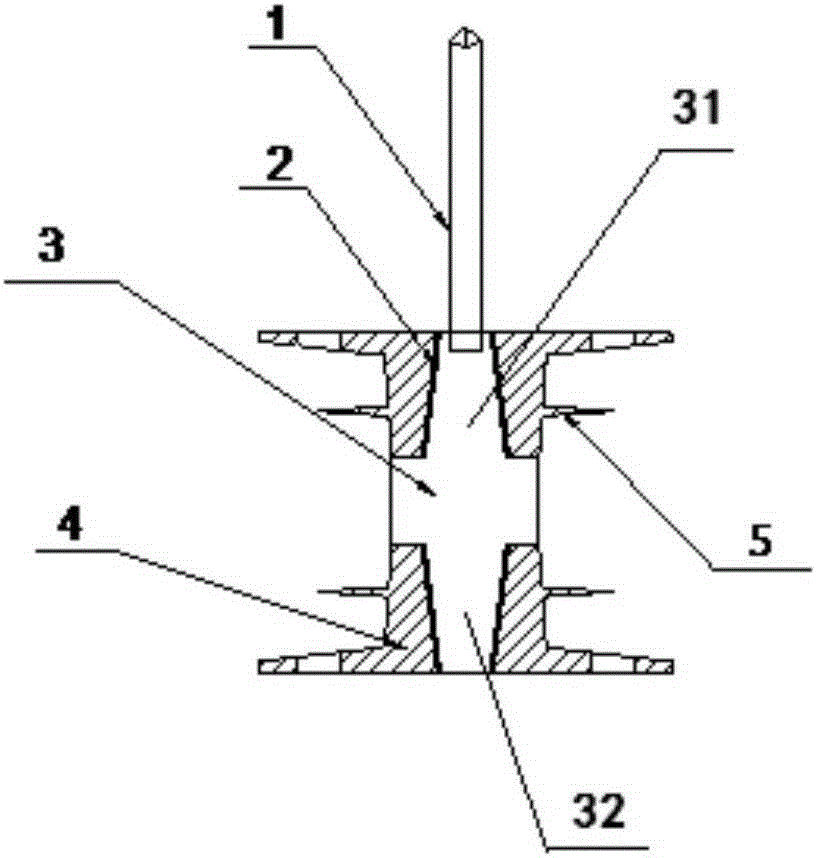

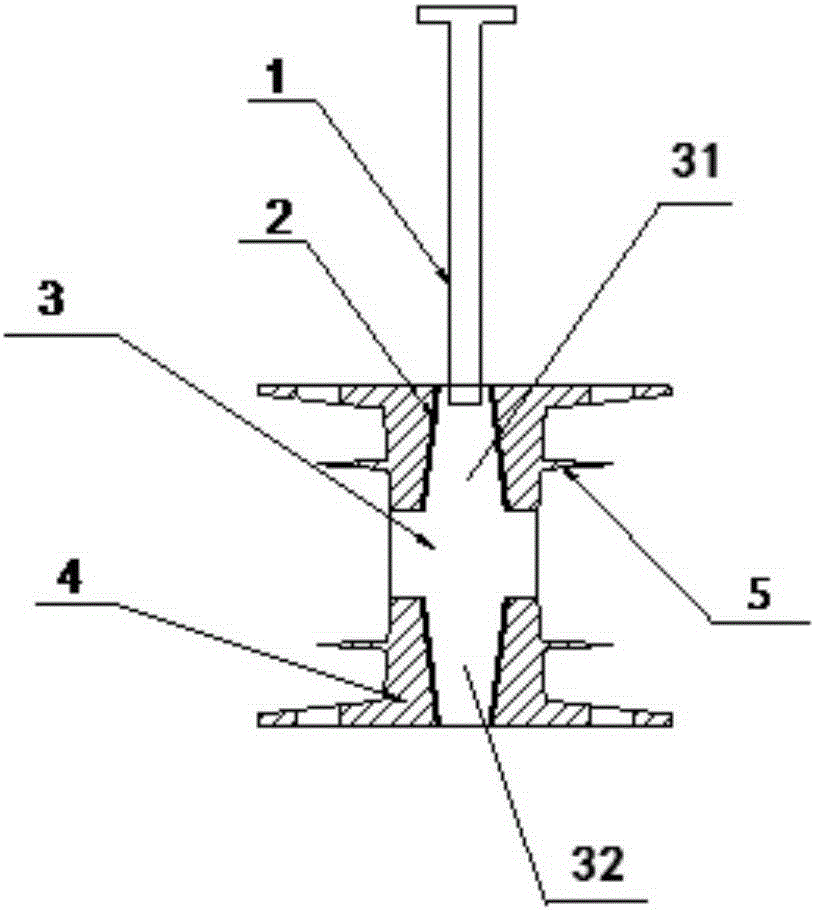

[0028] refer to figure 1 and figure 2 , The strut of the present invention includes: a core column 3 , a pair of bases 4 connected to the core column 3 and a connecting piece 1 fixedly connected to the core column 3 . The stem 3 includes a first end portion 31 and a second end portion 32 disposed opposite to each other. A pair of bases 4 are detachably connected to the first end portion 31 and the second end portion 32 respectively. Therefore, the stud of the present invention realizes the assembly of the base 4 and the stem 3, and the base 4 of the same specification can be combined with the height-adjustable stem 3, so as to solve the confusion defect that the studs of various specifications are used in the same product , Improve the interchangeability and use efficiency of the core support.

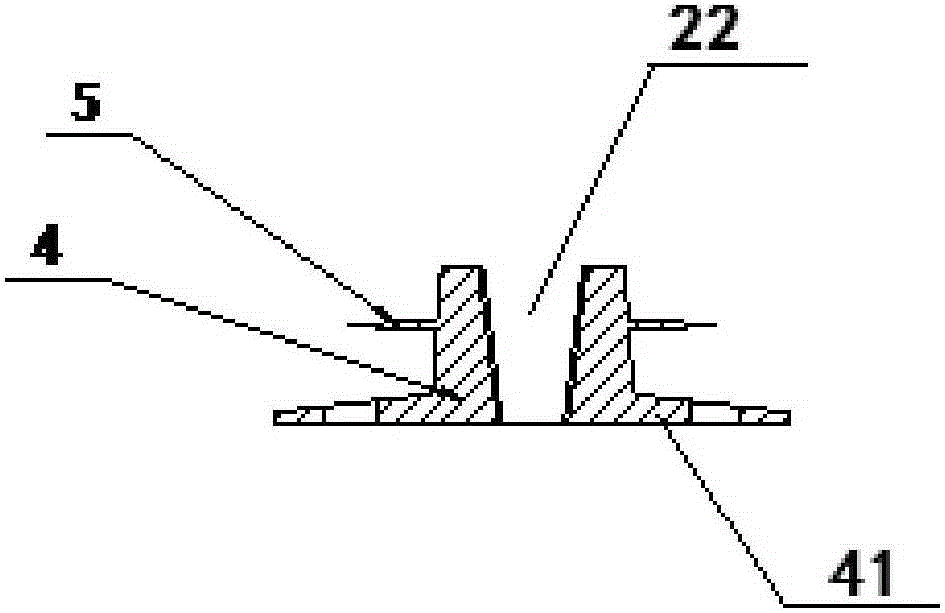

[0029] refer to Figure 1-3 , the base 4 includes a mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com