Grower for effectively restraining gallium oxide crystal defects

A technology for crystal defects and growth devices, applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., to achieve the effects of extending service life, reducing loss, and suppressing the content of impurity elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

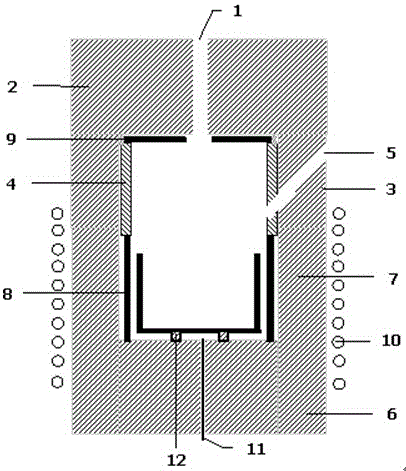

[0026] Embodiment: The present invention provides a growth device design that effectively suppresses defects in gallium oxide crystals, and is also suitable for growing large-sized gallium oxide crystals by using the guided mode method or the pulling method. Specifically, the following steps can be taken:

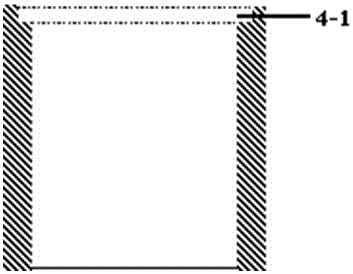

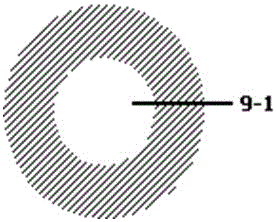

[0027] First, install heat preservation and heating thermal field components in the single crystal furnace. The thermal field components include a lower thermal insulation component 6 made of zirconia fiber boards that surrounds the heating element 8, an iridium crucible 7, and an oxide crucible that supports the iridium reflector 9. Zirconium inner insulation cylinder 4, upper insulation part 2 and middle insulation part 3 made of zirconia fiberboard, iridium reflective screen 9 and circular induction coil 10 surrounding the insulation component group. The purity of each thermal field component material is higher than 99.7%.

[0028] The heating element 8 is separated fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com