A kind of regenerative energy-saving and environment-friendly charcoal and preparation method thereof

An energy-saving, environment-friendly and charcoal technology, applied in the charcoal field, can solve the problems of ineffective utilization of sawdust and waste wood, environmental pollution, economic losses, etc., achieve a good sustainable development prospect, suppress emission concentration, and reduce energy waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

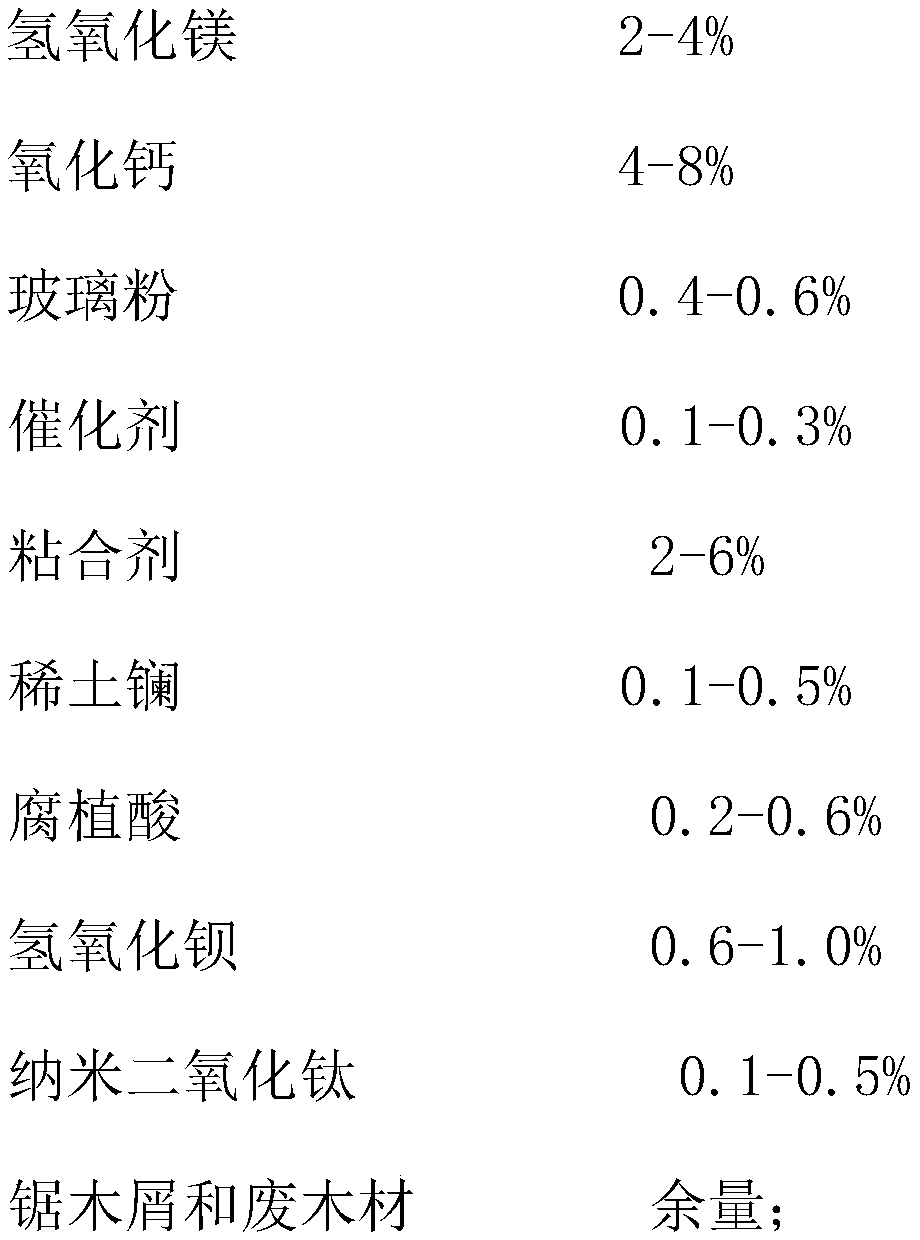

[0036] A kind of regenerated energy-saving and environment-friendly charcoal, said regenerated energy-saving and environment-friendly charcoal comprises the following raw materials by weight percentage:

[0039] Glass powder 0.4%

[0040] Catalyst 0.1%

[0041] Sawdust and waste wood surplus.

[0042] The particle size of the glass powder is 80 mesh.

[0043] The catalyst is potassium nitrate.

[0044] The particle size of the sawdust is 0.1mm.

[0045] The regenerated, energy-saving and environment-friendly charcoal also includes 2% binder, and the binder is paper waste liquid.

[0046] A preparation method of regenerated energy-saving and environment-friendly charcoal, comprising the steps of:

[0047] (1) The waste wood is crushed first, and the sawdust and the crushed waste wood are carbonized by an environmental protection carbonization machine;

[0048] (2) Add magnesium hydroxide, calcium oxide, glass pow...

Embodiment 2

[0052] The difference between this embodiment and the above-mentioned embodiment 1 is that the regenerated energy-saving and environment-friendly charcoal includes the following raw materials in weight percentage:

[0053] Magnesium Hydroxide 2.5%

[0055] Glass powder 0.45%

[0056] Catalyst 0.15%

[0057] Sawdust and waste wood surplus.

[0058] The particle size of the glass powder is 85 mesh.

[0059] The catalyst is potassium carbonate.

[0060] The particle size of the sawdust is 0.3mm.

[0061] The regenerated, energy-saving and environment-friendly charcoal also includes 3% binder, and the binder is paper waste liquid.

[0062] After testing, the regeneration, energy-saving and environment-friendly charcoal prepared in this embodiment can remove 93% of carbon dioxide and sulfur dioxide during combustion, and the combustion time is 25% longer than that of traditional charcoal.

Embodiment 3

[0064] The difference between this embodiment and the above-mentioned embodiment 1 is that the regenerated energy-saving and environment-friendly charcoal includes the following raw materials in weight percentage:

[0067] Glass powder 0.5%

[0068] Catalyst 0.2%

[0069] Sawdust and waste wood surplus.

[0070] The particle size of the glass powder is 90 mesh.

[0071] The catalyst is potassium chloride.

[0072] The particle size of the sawdust is 0.5mm.

[0073] The regenerated, energy-saving and environment-friendly charcoal also includes 4% binder, and the binder is paper waste liquid.

[0074] After testing, the regeneration, energy-saving and environment-friendly charcoal prepared in this embodiment can remove 95% of carbon dioxide and sulfur dioxide during combustion, and the combustion time is 30% longer than that of traditional charcoal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com