Water-based acrylic polyurethane paint and preparation method thereof

A technology of acrylic polyurethane and hydroxyacrylic acid, which is applied in the field of coatings, can solve the problems of slow drying of coating films, increase of VOC content in coatings, increase of VOC content, etc., and achieve the effects of fast drying speed, convenient construction and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

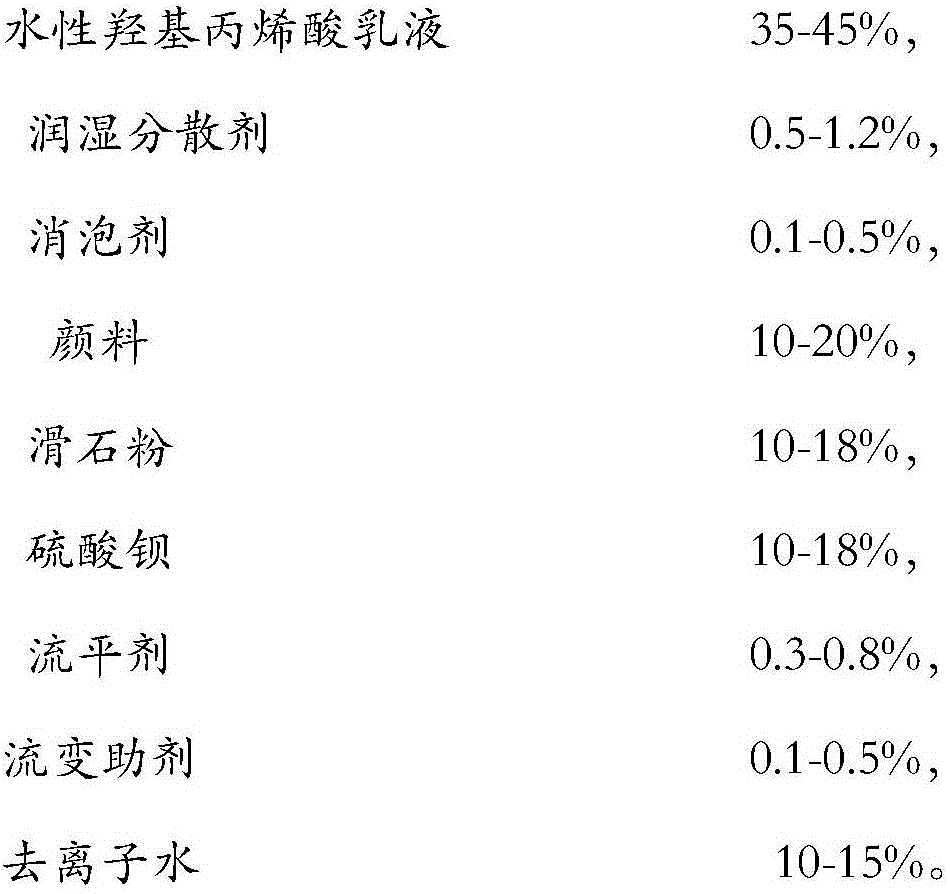

[0023] A kind of waterborne acrylic polyurethane intermediate paint of the present invention, described waterborne acrylic polyurethane intermediate paint is made up of A component and B component, and B component is curing agent; Described A component is made up of the following components by weight percentage :

[0024]

[0025] The weight ratio of the A component and the B component is 5:1.

[0026] The water-based hydroxyl acrylic emulsion is S6520 of the Nupace brand.

[0027] The curing agent is XP2840 of Covestro brand.

[0028] The preparation method of paint in waterborne acrylic polyurethane of the present invention is characterized in that comprising the steps:

[0029] (1) Preparation of component A: Weigh each component by weight percentage, and mix water-based hydroxyacrylic emulsion, wetting and dispersing agent, defoamer, pigment, talcum powder, barium sulfate, leveling agent, rheology additive, Ionized water is sequentially added to the stock preparation...

Embodiment 2

[0033] A kind of waterborne acrylic polyurethane intermediate paint of the present invention, described waterborne acrylic polyurethane intermediate paint is made up of A component and B component, and B component is curing agent; Described A component is made up of the following components by weight percentage :

[0034]

[0035] The weight ratio of the A component and the B component is 7:1.

[0036] The water-based hydroxyl acrylic emulsion is S6520 of the Nupace brand.

[0037] The curing agent is Covestro brand N3900.

[0038] The preparation method of paint in waterborne acrylic polyurethane of the present invention is characterized in that comprising the steps:

[0039] (1) Preparation of component A: Weigh each component by weight percentage, and mix water-based hydroxyacrylic emulsion, wetting and dispersing agent, defoamer, pigment, talcum powder, barium sulfate, leveling agent, rheology additive, Add ionized water to the stock preparation pot in turn, and disp...

Embodiment 3

[0043] A kind of waterborne acrylic polyurethane intermediate paint of the present invention, described waterborne acrylic polyurethane intermediate paint is made up of A component and B component, and B component is curing agent; Described A component is made up of the following components by weight percentage :

[0044]

[0045] The weight ratio of the A component and the B component is 8:1.

[0046] The water-based hydroxyl acrylic emulsion is S6520 of the Nupace brand.

[0047] The curing agent is WL72-100.

[0048] The preparation method of paint in waterborne acrylic polyurethane of the present invention is characterized in that comprising the steps:

[0049] (1) Preparation of component A: Weigh each component by weight percentage, and mix water-based hydroxyacrylic emulsion, wetting and dispersing agent, defoamer, pigment, talcum powder, barium sulfate, leveling agent, rheology additive, Add ionized water into the stock preparation pot in turn, and disperse to a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com