Preparation method of rare earth heat stabilizer

A rare earth heat stabilizer and rare earth technology, which are applied in the field of PVC heat stabilizers, can solve the problems of slow reaction speed, many industrial waste water, and few types of reagents, etc., and achieve the effects of improving yield, simple operation process and improving mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

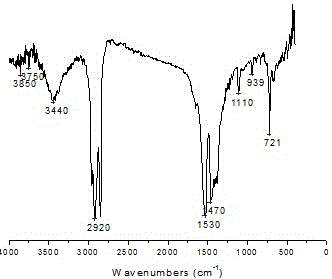

Image

Examples

Embodiment 1

[0019] A preparation method of rare earth heat stabilizer, comprising the following steps:

[0020] (1) Dissolve lanthanum nitrate and neodymium nitrate in ethanol to prepare a rare earth-ethanol solution with a concentration of 2.4 mol / L. Control the molar ratio of lanthanum nitrate and neodymium nitrate to 0.78:0.25, move the rare earth-ethanol solution into the reaction vessel, and heat to 90°C;

[0021] (2) Prepare an aqueous sodium hydroxide solution with a concentration of 1.2mol / L, and add it dropwise to the rare earth-ethanol solution, control the molar ratio of hydroxide ions to two rare earth cations to be 3:1.03, and react for 15 minutes;

[0022] (3) Add stearic acid into the reaction vessel three times, 50% of the total amount of stearic acid is added for the first time, 30% of the total amount is added for the second time, 20% of the total amount is added for the third time, and stearic acid is controlled. The molar ratio of the acid to the rare earth cation is ...

Embodiment 2

[0026] A preparation method of rare earth heat stabilizer, comprising the following steps:

[0027] (1) Dissolve lanthanum nitrate and neodymium nitrate in ethanol to prepare a rare earth-ethanol solution with a concentration of 2.4 mol / L. Control the molar ratio of lanthanum nitrate and neodymium nitrate to 0.78:0.25, move the rare earth-ethanol solution into the reaction vessel, and heat to 80°C;

[0028] (2) Prepare an aqueous sodium hydroxide solution with a concentration of 1.2mol / L, and add it dropwise to the rare earth-ethanol solution, control the molar ratio of hydroxide ions to two rare earth cations to be 3:1.03, and react for 20 minutes;

[0029] (3) Add stearic acid into the reaction vessel three times, 50% of the total amount of stearic acid is added for the first time, 30% of the total amount is added for the second time, 20% of the total amount is added for the third time, and stearic acid is controlled. The molar ratio of the acid to the rare earth cation is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com