Method for manufacturing part by means of additive manufacturing technique

A manufacturing technology, a technology for components, applied in the field of additive manufacturing, which can solve the problems of high cost and time-consuming correction of manufacturing steps or additional support structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

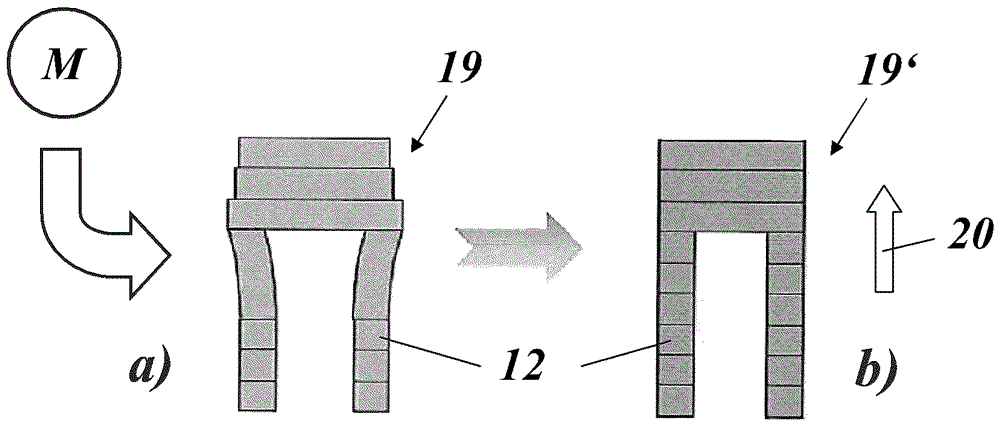

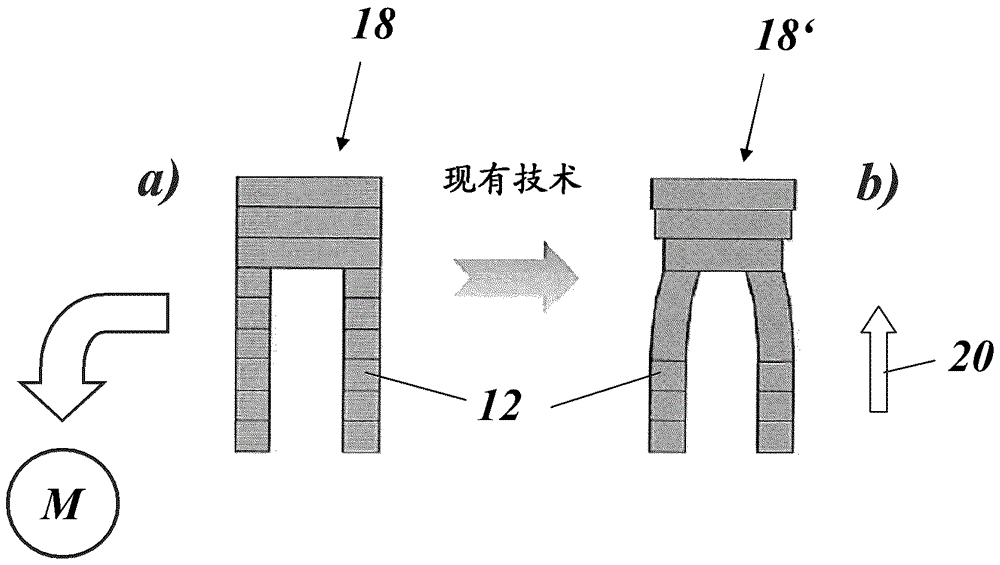

[0045] The method used by the present invention is fundamentally different from the method according to the above-mentioned document EP 2361720B1: in the present invention, the (original) CAD profile (18 in Fig. Gradient CAD designs of different shapes of the resulting part 19' (19 in Fig. 3(a)).

[0046] This is done by taking into account all deformations / distortions that will occur during the SLM process and all related subsequent post-AM fabrication steps (eg removal of the component from the substrate plate, heat treatment HT, etc.). Thus, although the SLM process uses as input a CAD section 19 (which has a different geometry than the target component 19'), the final result (19' in Figure 3(b)) will be completely accurate to the target design (CAD design 18) match, whereas fabrication based on the non-gradient CAD design 18 results in a distorted component 18' (Fig. 2(b)).

[0047] Essentially, the geometry of a part to be manufactured using additive manufacturing techni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com