Punching production main machine

A main engine and punching technology, applied in the direction of piercing tools, metal processing equipment, manufacturing tools, etc., can solve the problems of low production efficiency, low safety factor, high work intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

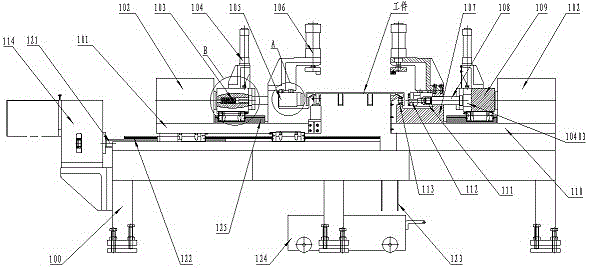

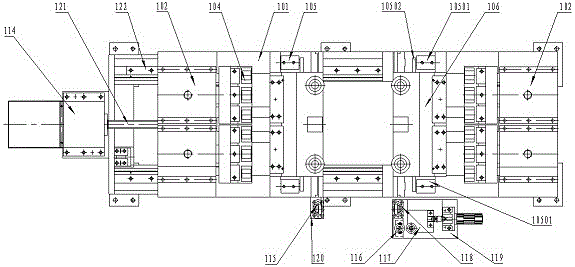

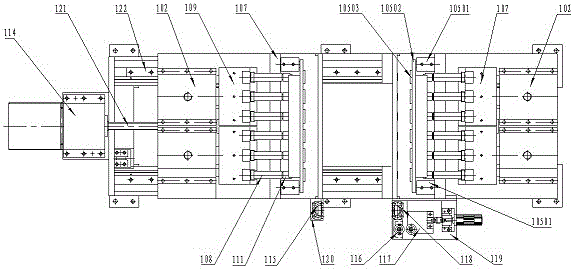

[0082] Such as Figure 1 to Figure 3 As shown, a punching production host includes a base, a punching device, a hydraulic power device and an electrical control device. The base is provided with a fixed base 110, a mobile base 101 and a driving device for the mobile base. The punching device includes a left punching device and a right punching device, the left punching device is arranged on the mobile base 101 , and the right punching device is arranged on the fixed base 110 .

[0083] The base 100 is provided with two first guide rails 122, and the mobile base driving device drives the mobile base 101 to move along the first guide rails 122 in the Y direction;

[0084] Mobile base drives include:

[0085] The servo power device 114 is fixed on the base 100,

[0086] Lead screw 121, one end links to each other with servo power unit 114, present embodiment adopts ball screw,

[0087] The screw nut is connected to the lower part of the mobile base 101 and meshes with the bal...

Embodiment 2

[0119] A punching production host, the upper pressing device 106 includes a cylinder bracket 10601, an upper pressing cylinder 10602, a guide post 10603, a guide sleeve 10604, a linear bearing, an upper pressing plate 10606, and an upper pressing block 10607; The lower end of the left side of the support 10601 is connected to the top of the left vertical plate of the formwork 107 with bolts, and the upper side pressing cylinder 10602 is vertically installed on the upper end of the right side of the cylinder support 10601, and the piston rod of the upper side pressing cylinder 10602 is connected with the upper side. The binder plate 10607 is fixed with bolts, and the guide sleeve 10604 is fixed on the cylinder bracket 10601 with bolts. The inner side of the guide sleeve 10604 is equipped with a linear bearing, and the guide post 10603 can slide along the linear bearing. The lower end of the guide post 10603 and the upper binder plate 10606 is connected with bolts, and the upper ...

Embodiment 3

[0122] A punching production host, the upper pressing device 106 includes a cylinder bracket 10601, a multi-axis cylinder, an upper pressing plate 10606, and an upper pressing block 10607; the lower end of the left side of the cylinder bracket 10601 is connected to the mold frame 107 by bolts On the upper part of the left vertical plate, the multi-axis cylinder is vertically installed on the upper end of the right side of the cylinder bracket 10601. The piston rod of the multi-axis cylinder is connected with the upper pressing plate 10607 with bolts, and the upper pressing block 10607 is connected with the upper pressing plate with bolts. The bottom surface of the material plate 10606; the rest of the structure is the same as that of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com