Comprehensive resource recycling method for waste cathode carbon blocks of aluminum cells

A technology of aluminum electrolytic cell waste and cathode carbon blocks, which is applied in the field of comprehensive utilization of solid waste resources, can solve the problems of ineffective recycling of valuable substances, high processing costs, and complicated processes, and achieve low raw material prices, high purity, and simple processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

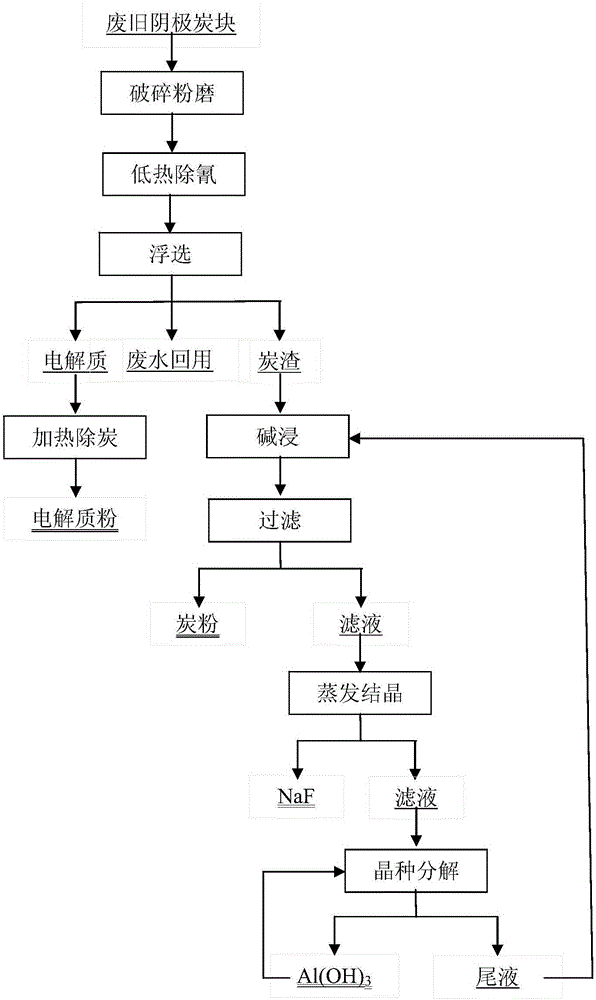

Method used

Image

Examples

Embodiment 1

[0049] Take 10g of the waste cathode carbon block of a domestic aluminum electrolytic cell, the main element content is (wt%): C70.9, Al8.23, O9.55, F5.38, Na2.57, Fe1.21, crush and grind to -200 mesh accounted for 90%, laid flat in a 9cm×6cm flat-bottomed square porcelain boat.

[0050] Put the porcelain boat containing the waste cathode powder in a muffle furnace, heat it to 400℃ and keep it for 30 minutes; the cyanide-removing waste cathode powder is mixed with water at a mass concentration of 25% to form a slurry, which is carried out by a single tank flotation machine Rough selection. The flotation inhibitor is water glass with a dosage of 320g / t waste cathode; the collector is kerosene with a dosage of 400g / t waste cathode; the foaming agent is No. 2 oil with a dosage of 40g / t waste cathode. The flotation foam and the underflow were washed with water and then dried and weighed. The obtained carbon residue and electrolyte residue were 7.35g and 2.46g, respectively.

[0051] ...

Embodiment 2

[0055] Take 30g of the waste cathode carbon block of an aluminum electrolytic cell in a domestic factory, the content of main elements is (wt%): C70.9, Al8.23, O9.55, F5.38, Na2.57, Fe1.21, crush and grind to -200 mesh accounted for 80%, laid flat in a 12cm×8cm flat-bottomed square porcelain boat.

[0056] Put the porcelain boat containing the waste cathode powder in a muffle furnace, heat it to 400℃ and keep it for 10 minutes; the cyanide-removing waste cathode powder is mixed with water at a mass concentration of 10% to form a slurry, which is carried out by a single tank flotation machine Rough selection. The flotation inhibitor is water glass with a dosage of 200g / t waste cathode; the collector is kerosene with a dosage of 600g / t waste cathode; the foaming agent is No. 2 oil with a dosage of 20g / t waste cathode. The flotation foam and the underflow were washed with water and then dried and weighed. The obtained carbon residue and electrolyte residue were 23.64g and 6.14g, re...

Embodiment 3

[0061] Take 100g of the waste cathode carbon block of an aluminum electrolytic cell in a domestic factory, and the main element content is (wt%): C70.9, Al8.23, O9.55, F5.38, Na2.57, Fe1.21, and crush the ink to -200 mesh accounted for 60%, laid flat in a square porcelain boat with a flat bottom of 12cm×8cm.

[0062] Put the porcelain boat containing the waste cathode powder in the muffle furnace, heat it to 300℃ and keep it for 60 minutes; the cyanide-removing waste cathode powder is mixed with water at a mass concentration of 30% to form a slurry, which is carried out by a single tank flotation machine Rough selection. The flotation inhibitor is water glass with a dosage of 320g / t waste cathode; the collector is kerosene with a dosage of 200g / t waste cathode; the foaming agent is No. 2 oil with a dosage of 100g / t waste cathode. The flotation foam and underflow were washed with water and then dried and weighed. The obtained carbon residue and electrolyte residue were 80.51g and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com