A new type of flexible parallel micro-positioning platform with large stroke

A technology of micro-positioning platform and large stroke, which is applied in the direction of machine/bracket, lifting device, lifting frame, etc., which can solve the problems of small deformation and limited working space, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

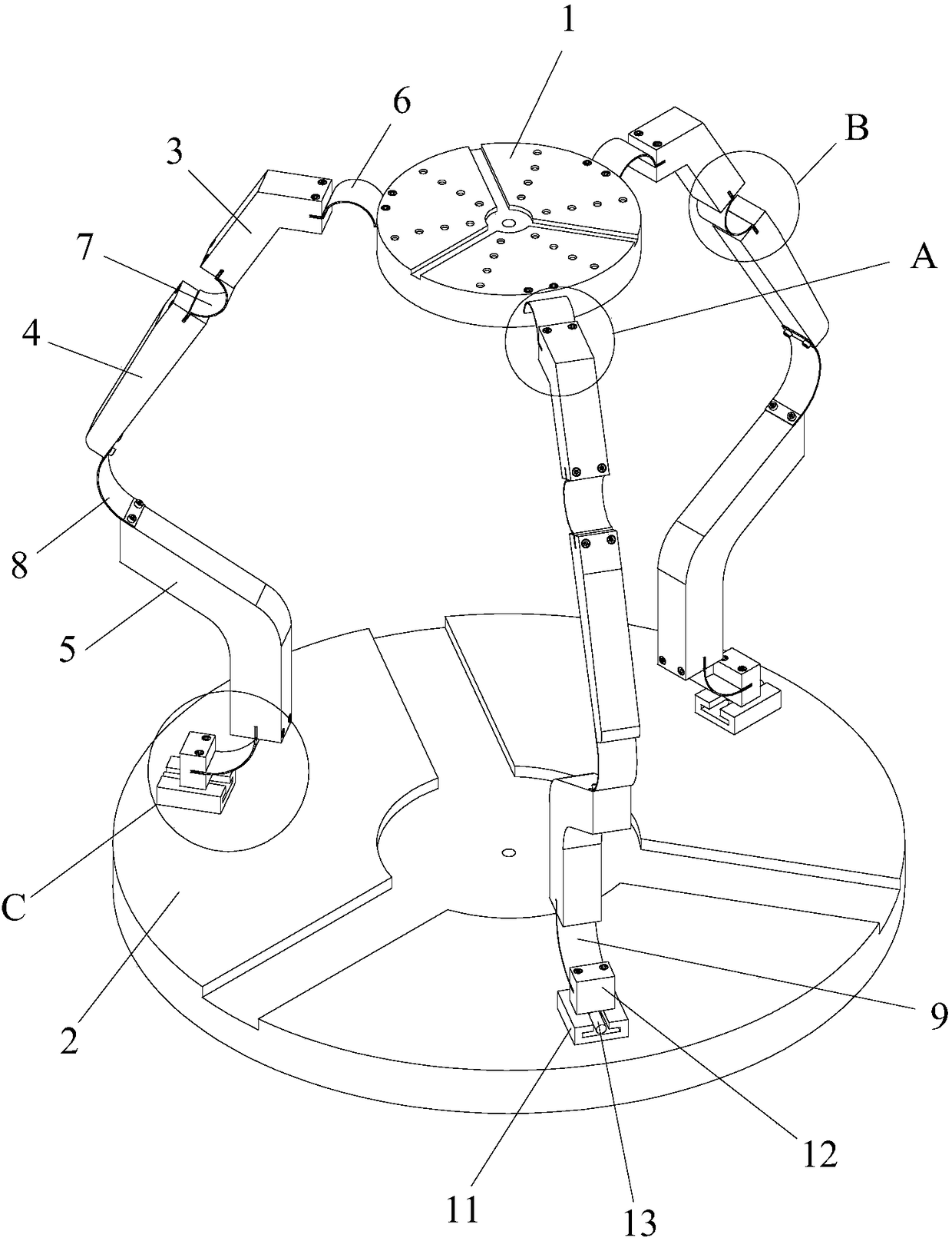

[0029] Such as Figure 1 to Figure 4 As shown in Fig. 1, a new type of large-stroke compliant parallel micro-positioning platform includes a moving platform 1, a fixed platform 2, a driving device set on the fixed platform 2, and three kinematic branch chains for connecting the fixed platform 2 and the moving platform 1, wherein , the moving platform 1 is located above the fixed platform 2, and the three moving branch chains are evenly distributed on the side of the moving platform 1. One end of each moving branch chain is connected to the driving device, and the other end is connected to the moving platform 1. Each moving branch chain is composed of Composed of rigid components and compliant joints.

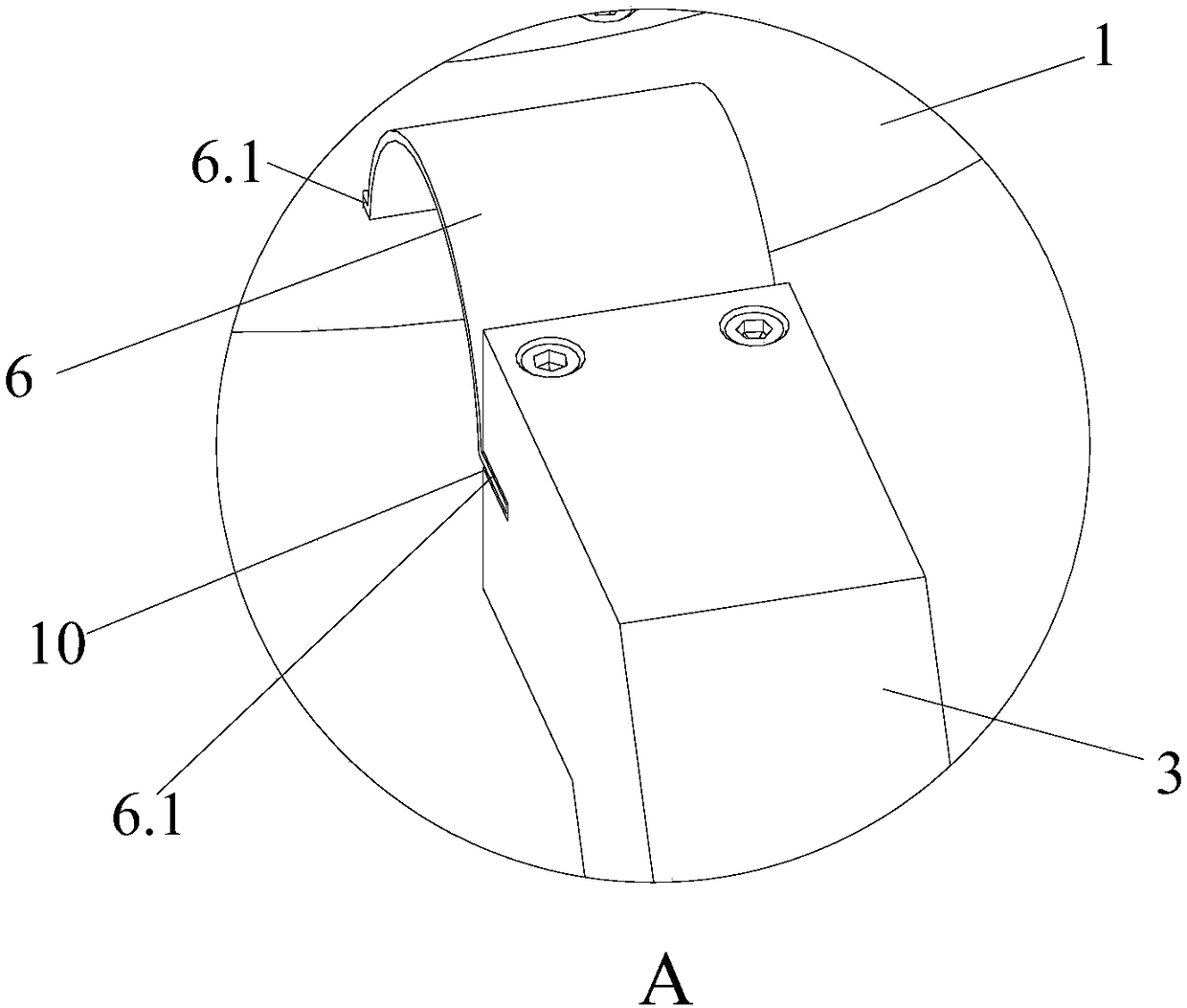

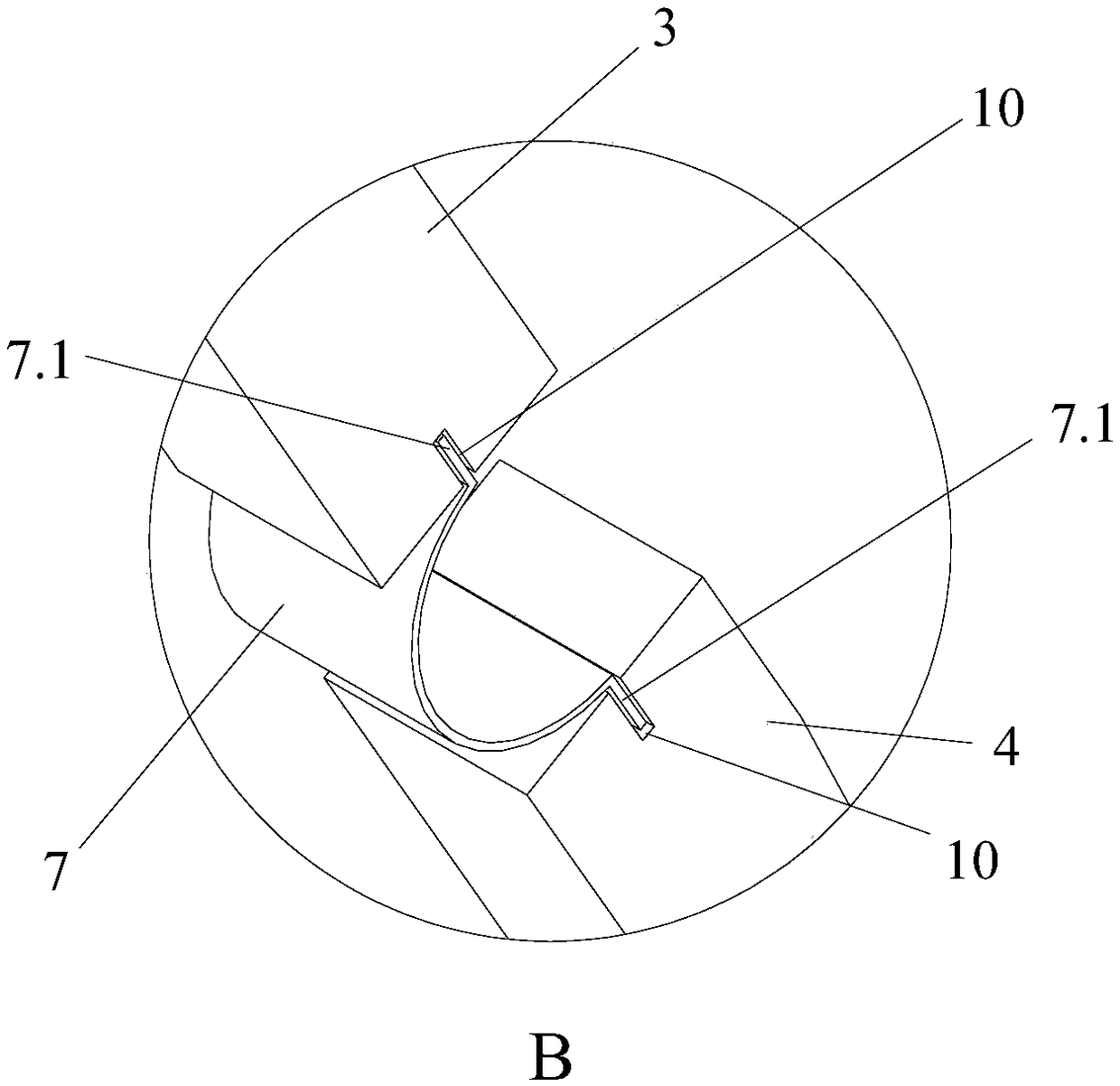

[0030] Each kinematic branch chain of the present invention is made up of rigid component and flexible joint connection means: each kinematic branch chain comprises rigid component one 3, rigid component two 4 and rigid component three 5; Rigid component one 3 and rigid componen...

Embodiment 2

[0037] The only difference between this embodiment and Embodiment 1 is that the compliant parallel micro-positioning platform may include two or more kinematic branch chains for connecting the fixed platform and the moving platform, wherein each kinematic branch chain is composed of rigid components and Composed of supple joint connections. Each kinematic branch chain includes several rigid components, and each rigid component is connected by compliant joints. The rigid components at both ends of each motion branch chain are respectively connected with compliant joints, and the rigid components at both ends of the motion branch chain are respectively connected with the moving platform and the driving device through the compliant joints. The openings of adjacent compliant joints in each kinematic branch chain are opposite.

[0038] The micro-positioning platform of this embodiment adopts two or more than four motion branch chains to realize two-degree-of-freedom or multi-degre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com