A Composite Rigid Core Pile with Stirring Thread Special-shaped Consolidation Body and Its Construction Method

A construction method and screw thread technology, which can be used in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problem of inability to guarantee the concentricity and sag of inner and outer piles, limit the compressive and uplift resistance of composite piles, and the bearing capacity of composite piles. Solve problems such as large force dispersion, achieve high settlement reliability, improve bearing capacity, and improve bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The method of constructing the outer pile 1 first and then the inner pile 3 is used to construct the composite rigid-core pile with a special-shaped consolidation body with spray-spraying thread, specifically: align the guide cone 10 of the closed-end spray-mixing drilling tool with the center of the pile position, start the power head, and the power The head drives the stirring shaft 4 of a closed-end spraying drilling tool to rotate, and the stirring shaft 4 drives the A fixed stirring wing 5 and the spiral excavating blade 7 to stir the soil and sink. During the sinking process, the grouting pump is started at the same time, and the cement slurry is Under the action of pressure, it is sent into the horizontal spray port 8 and the vertical spray port 9 to spray into the soil; when the stirring shaft 4 sinks to the predetermined depth, the rotation direction of the power head is switched and the stirring shaft of the closed-end spraying drilling tool is driven. 4 rotate...

Embodiment 2

[0042] The method of first constructing the inner pile 3 and then constructing the outer pile 1 is to construct the composite rigid-core pile with a special-shaped consolidation body with sprayed threads, specifically:

[0043]1) Construct the inner pile 3 first; the construction method is: use piling equipment to drive, press, or vibrate the concrete square pile into the soil.

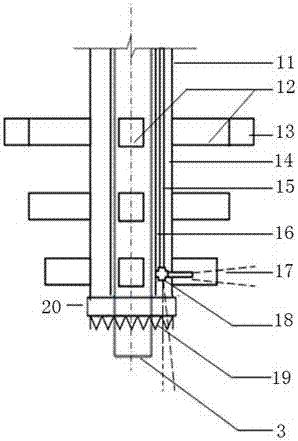

[0044] 2) Then cover the inner pile 3 with the open-type jet-mixing drilling tool. The inner pile 3 is the "track" for the construction of the outer pile 1. The inner pile 3 and the open-type jet-mixing drilling tool maintain concentricity and verticality, and then start Grouting pump, the cement slurry is injected into the soil from the slurry reversing valve 18 through the horizontal nozzle 17, and the power head is started at the same time to drive the spray and agitation drilling tool 11 to rotate and sink;

[0045] 3) When the jet-stirring drilling tool 11 sinks to the same depth as the outer pil...

Embodiment 3

[0047] The method of first constructing the inner pile 3 and then constructing the outer pile 1 is to construct the composite rigid-core pile with the special-shaped consolidation body of the sprayed thread, specifically:

[0048] 1) Construct the inner pile 3 first; the construction method is: use piling equipment to drive, press, or vibrate the concrete square pile into the soil.

[0049] 2) Then cover the inner pile 3 with the open-type jet-mixing drilling tool. The inner pile 3 is the "track" for the construction of the outer pile 1. The inner pile 3 and the open-type jet-mixing drilling tool maintain concentricity and verticality, and then start Grouting pump, the cement slurry is injected into the soil from the slurry reversing valve 18 through the horizontal nozzle 17, and the power head is started at the same time to drive the spray and agitation drilling tool 11 to rotate and sink;

[0050] 3) When the spraying and stirring drill 11 sinks to half the depth of the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com