Nano-copper regenerated cellulose fiber and preparation method thereof

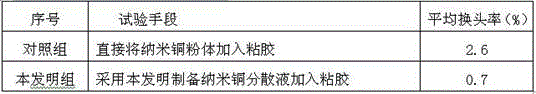

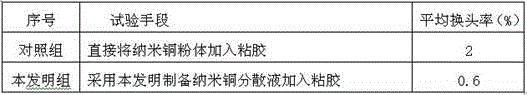

A technology of regenerated cellulose and nano-copper, applied in the fiber field, can solve problems such as easy shedding, nano-copper agglomeration, affecting spinnability and finished fiber indicators, and achieves the effect of not being easy to shed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

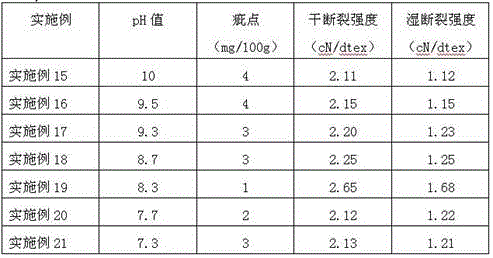

Examples

Embodiment 1

[0041] Example 1 Preparation of Nano Copper Regenerated Cellulose Fibers

[0042] Nano copper dispersion preparation:

[0043] (1) Suspension preparation: Add nano-copper powder into deionized water with a hardness lower than 1. The purity of the nano-copper powder is 99.5%, particle size D90: 1um, specific surface area: 4.0m 2 / g, the conductivity of the deionized water: 500us / cm, made of nano-copper suspension, the addition ratio of nano-copper powder is 5g / 100ml, and then add 1 wt% hexadecyl trimethyl bromide Ammonium (CTAB) dispersant, stir well.

[0044] (2) Ultrasonic treatment: Ultrasonic treatment was used for 15 minutes, and the pH was adjusted to 7.5 with NaOH and acetic acid to prepare a 5 wt% nano-copper dispersion for use.

[0045] Preparation of spun viscose: cellulose pulp is used as raw material, and the spun viscose collagen solution is obtained through impregnation, pressing, crushing, aging, yellowing, filtering, aging and degassing.

[0046] Ball m...

Embodiment 2

[0055] Example 2 Preparation of Nano Copper Regenerated Cellulose Fibers

[0056] Nano copper dispersion preparation:

[0057] (1) Suspension preparation: Add nano-copper powder into deionized water with a hardness lower than 1. The nano-copper powder has a purity of 99.6%, a particle size D90 of 0.8um, and a specific surface area of 4.0m 2 / g, the conductivity of the deionized water: 450us / cm, made of nano-copper suspension, the addition ratio of nano-copper powder is 10g / 100ml, to which 2 wt% cetyl trimethyl bromide is added Ammonium (CTAB) dispersant, stir well.

[0058] (2) Ultrasonic treatment: Sonicate for 25 minutes, adjust the pH to 8.0 with NaOH and acetic acid, and prepare a 10 wt% nano-copper dispersion for use.

[0059] Preparation of spun viscose: cellulose pulp is used as raw material, and the spun viscose collagen solution is obtained through impregnation, pressing, crushing, aging, yellowing, filtering, aging and degassing.

[0060] Ball milling: The...

Embodiment 3

[0069] Example 3 Preparation of Nano Copper Regenerated Cellulose Fibers

[0070] Nano copper dispersion preparation:

[0071] (1) Suspension preparation: Add nano-copper powder into deionized water with a hardness lower than 1. The nano-copper powder has a purity of 99.9%, particle size D90: 0.89um, and specific surface area: 4.5m 2 / g, the conductivity of the deionized water: 400us / cm, made of nano-copper suspension, the addition ratio of nano-copper powder is 15g / 100ml, to which 3 wt% cetyl trimethyl bromide is added Ammonium (CTAB) dispersant, stir well.

[0072] (2) Ultrasonic treatment: Ultrasonic treatment for 30 min, adjust the pH to 8.8 with NaOH and acetic acid, and prepare a 15 wt% nano-copper dispersion for use.

[0073] Preparation of spun viscose: cellulose pulp is used as raw material, and the spun viscose collagen solution is obtained through impregnation, pressing, crushing, aging, yellowing, filtering, aging and degassing.

[0074] Ball milling: The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com