A kind of steel for construction machinery with yield strength ≥ 960mpa and its production method

A yield strength, engineering machinery technology used in low alloy steel and its production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below:

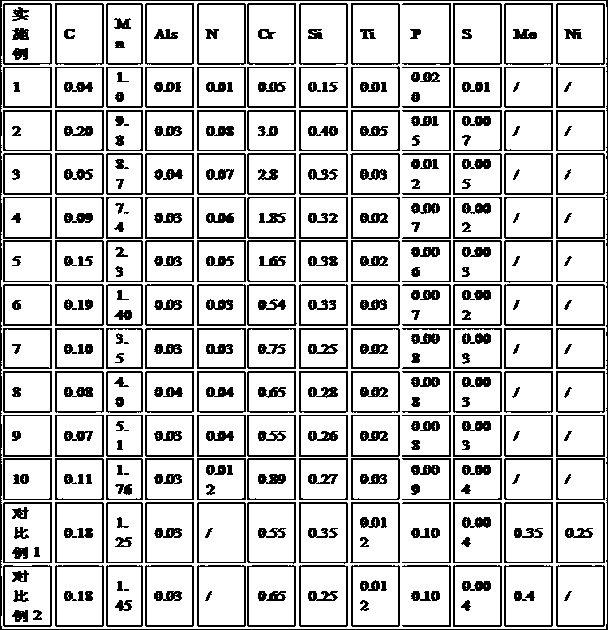

[0025] Table 1 is the value list of each embodiment of the present invention and comparative examples;

[0026] Table 2 is the main process parameter list of each embodiment of the present invention and comparative example;

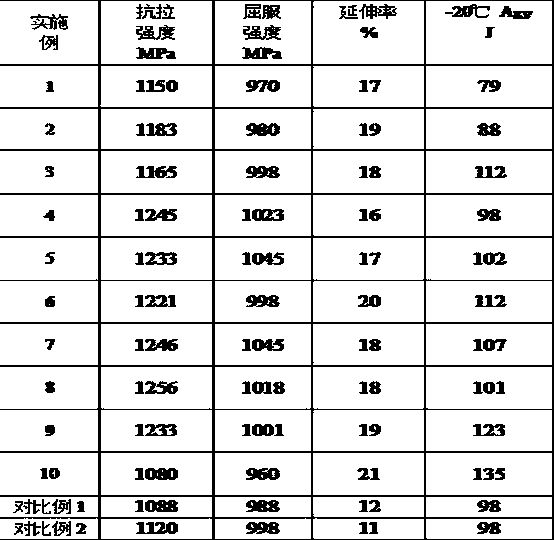

[0027] Table 3 is a list of the performance tests of the various embodiments of the present invention and comparative examples.

[0028] Each embodiment of the present invention is produced according to the following production process:

[0029] 1) Smelting, after adding low-carbon ferromanganese and pure iron raw materials according to the composition ratio during smelting, vacuum treatment is carried out, and after the vacuum treatment is completed, ferrotitanium and nitrogen with a particle size of 1~3mm are added to the vacuum furnace according to the proportion ferrochromium;

[0030] 2) Tapping and pouring into billets: During this period, tapping and casting into billets within 8 to 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com