Method for obtaining lubricating oil containing lubrication-friendly MoS2 nano-particles

A nano-particle and lubricating oil technology, applied in lubricating compositions, petroleum industry, additives, etc., can solve the problems affecting anti-wear and anti-friction, unresearched, anti-oxidation, anti-saponification, and complex detergency, so as to improve anti-wear and anti-friction. The effect of anti-friction properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment includes the following steps:

[0039] In the first step, get 0.1g ZDDP and add it to the ball mill jar;

[0040] Described ball mill jar refers to: nylon ball mill jar, volume is 100ml;

[0041] The second step, take 0.4cm 3 MoS 2 Granular raw materials are added to the ball mill tank;

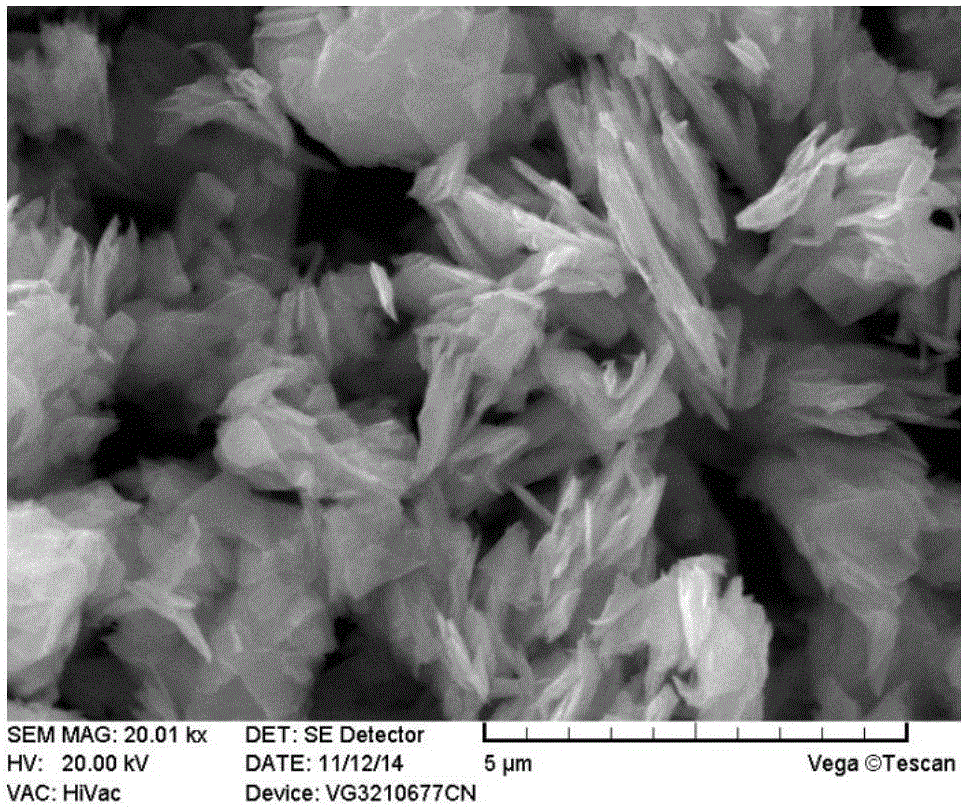

[0042] refer to figure 1 , the particles refer to MoS with an average particle size of 2-3 μm 2 particles;

[0043] The MoS 2 Particle volume is 0.4cm 3 , about 2g;

[0044] In the third step, a total of 50g of zirconia balls of 8mm and 3mm are added to the ball mill jar in a ratio of 1:1;

[0045] The material of the ball is: stainless steel ball, zirconia ball, etc.;

[0046] Step 4: Start the high-energy ball mill for ball milling, set the time to 30h, and the speed to 400rpm to obtain lubrication-friendly MoS 2 nanoparticles;

[0047] The fifth step is to take the above lubrication-friendly MoS 2 Add 0.1g of nanoparticles to 10g of paraffin oil, and ult...

Embodiment 2

[0053] This embodiment includes the following steps:

[0054] In the first step, take 0.1g T154 and add it to the ball mill jar;

[0055] Described ball mill jar refers to: nylon ball mill jar, volume is 100ml;

[0056] The second step, take 0.5cm 3 MoS 2 Granular raw materials are added to the ball mill tank;

[0057] The particles mentioned refer to MoS with an average particle size of 2-3 μm 2 particles, such as figure 1 shown;

[0058] In the third step, a total of 60g of zirconia balls of 3mm and 1mm are added to the ball mill jar in a ratio of 3:1;

[0059] Step 4: Start the high-energy ball mill for ball milling, set the time to 60h, and the speed to 600rpm to obtain T154-modified lubrication-friendly MoS 2 nanoparticles;

[0060] The fifth step is to take the above lubrication-friendly MoS 2 Add 0.2g of nanoparticles to 20g of paraffin oil, and ultrasonically disperse for 15min.

[0061] The ultrasonic dispersion is: working frequency 40kHz; ultrasonic power ...

Embodiment 3

[0065] This embodiment includes the following steps:

[0066] In the first step, take 0.2gMoDDP and add it to the ball mill jar;

[0067] Described ball mill jar refers to: nylon ball mill jar, volume is 100ml;

[0068] The second step, take 0.2cm 3 MoS 2 Granular raw materials are added to the ball mill tank;

[0069] The particles mentioned refer to MoS with an average particle size of 2-3 μm 2 particles, such as figure 1 shown;

[0070] In the third step, a total of 30g of zirconia balls of 8mm and 5mm are added to the ball mill jar in a ratio of 6:1;

[0071] Step 4: Start the high-energy ball mill for ball milling, set the time to 40h, and the speed to 600rpm to obtain MoDTP-modified lubrication-friendly MoS 2 nanoparticles;

[0072] The fifth step is to take the above lubrication-friendly MoS 2 Add 0.1g of nanoparticles to 10g of paraffin oil, and ultrasonically disperse for 30min.

[0073] The ultrasonic dispersion is: working frequency 40kHz; ultrasonic power...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com