Polyaniline-iron attapulgite composite material and synthesis and application method thereof

A technology of attapulgite and composite materials, applied in chemical instruments and methods, water treatment of special compounds, water/sludge/sewage treatment, etc., can solve the problem that ferrous iron cannot be reused and the degradation efficiency of atrazine is low , low utilization rate of Fenton's reagent, etc., to achieve the effect of repeated utilization, environmental friendliness and easy settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

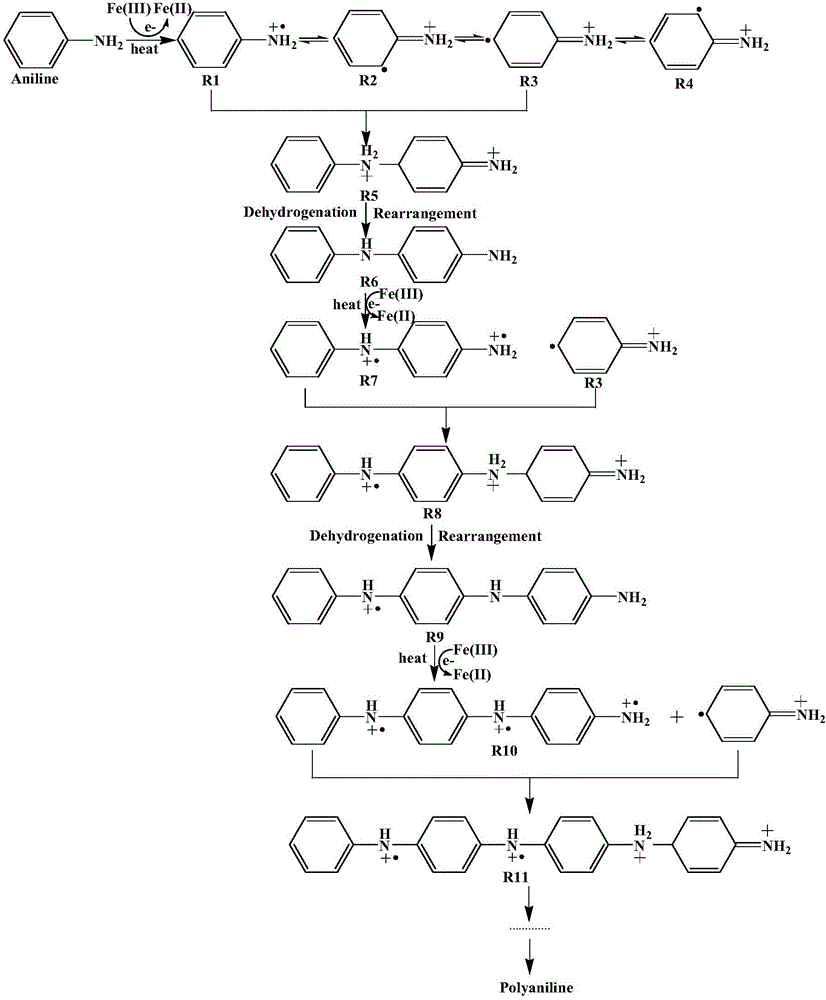

Method used

Image

Examples

Embodiment 1

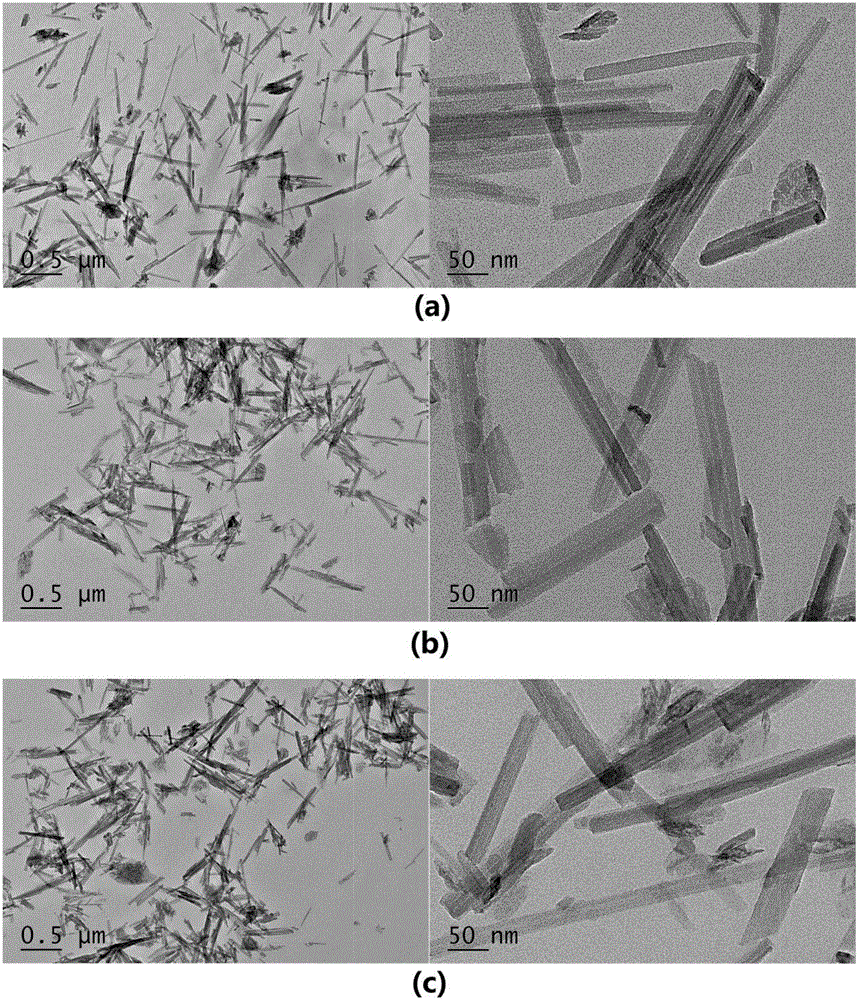

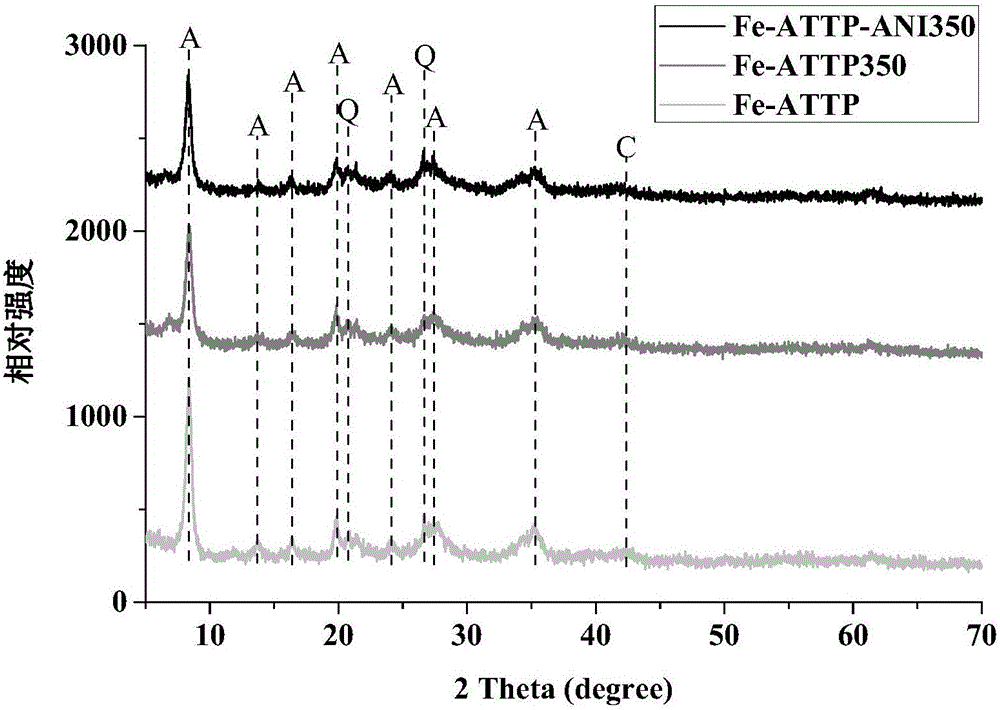

[0054] The synthesis is used for the characterization of the material of degrading organic pesticide atrazine, and its steps are:

[0055](1) Put sodium attapulgite (purchased from Xuyi Xinyuan Technology Co., Ltd., the total cation exchange capacity of attapulgite is 250-300mmol / kg) in 0.1mol / L FeCl 3 Stir in the solution for 8 hours, so that the iron ions replace the sodium ions in the pores of attapulgite, and obtain the clay that absorbs iron ions in the pores; then centrifuge to discard the supernatant, and place the precipitate in 0.1mol / L FeCl 3 solution, so repeated 6 times to get Fe as reported in the literature 3+ Saturated iron attapulgite. After washing the clay with ultrapure water to the supernatant with AgNO 3 The solution was detected without precipitation. Freeze-dried to obtain loaded Fe 3+ iron attapulgite.

[0056] (2) dry iron attapulgite (0.5g) and aniline (60mg) are placed in a high-temperature and high-pressure reactor (the placement method is: fir...

Embodiment 2

[0059] The synthesis is used for the characterization of the material of degrading organic pesticide atrazine, and its steps are:

[0060] (1) Put sodium attapulgite (purchased from Xuyi Xinyuan Technology Co., Ltd., the total cation exchange capacity of attapulgite is 250-300mmol / kg) in 0.1mol / L FeCl 3 Stir in the solution for 8 hours, so that the iron ions replace the sodium ions in the pores of attapulgite, and obtain the clay that absorbs iron ions in the pores; then centrifuge to discard the supernatant, and place the precipitate in 0.1mol / L FeCl 3 solution, so repeated 6 times to get Fe as reported in the literature 3+ Saturated iron attapulgite. After washing the clay with ultrapure water to the supernatant with AgNO 3 The solution was detected without precipitation. Freeze-dried to obtain loaded Fe 3+ iron attapulgite.

[0061] (2) dry iron attapulgite (0.5g) and aniline (60mg) are placed in a high-temperature and high-pressure reactor (the placement method is: fi...

Embodiment 3

[0064] The synthesis is used for the characterization of the material of degrading organic pesticide atrazine, and its steps are:

[0065] (1) Put sodium attapulgite (purchased from Xuyi Xinyuan Technology Co., Ltd., the total cation exchange capacity of attapulgite is 250-300mmol / kg) in 0.1mol / L FeCl 3 Stir in the solution for 8 hours, so that the iron ions replace the sodium ions in the pores of attapulgite, and obtain the clay that absorbs iron ions in the pores; then centrifuge to discard the supernatant, and place the precipitate in 0.1mol / L FeCl 3 solution, so repeated 6 times to get Fe as reported in the literature 3+ Saturated iron attapulgite. After washing the clay with ultrapure water to the supernatant with AgNO 3 The solution was detected without precipitation. Freeze-dried to obtain loaded Fe 3+ iron attapulgite.

[0066] (2) dry iron attapulgite (0.5g) and aniline (60mg) are placed in a high-temperature and high-pressure reactor (the placement method is: fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com