Anti-runaway protection system and method for downward belt conveyor

A belt conveyor and protection system technology, applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve problems such as inability to work, lack of control and adjustment of operating speed, etc., to achieve reduced impact, good use effect, and convenience The effect of promotional use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

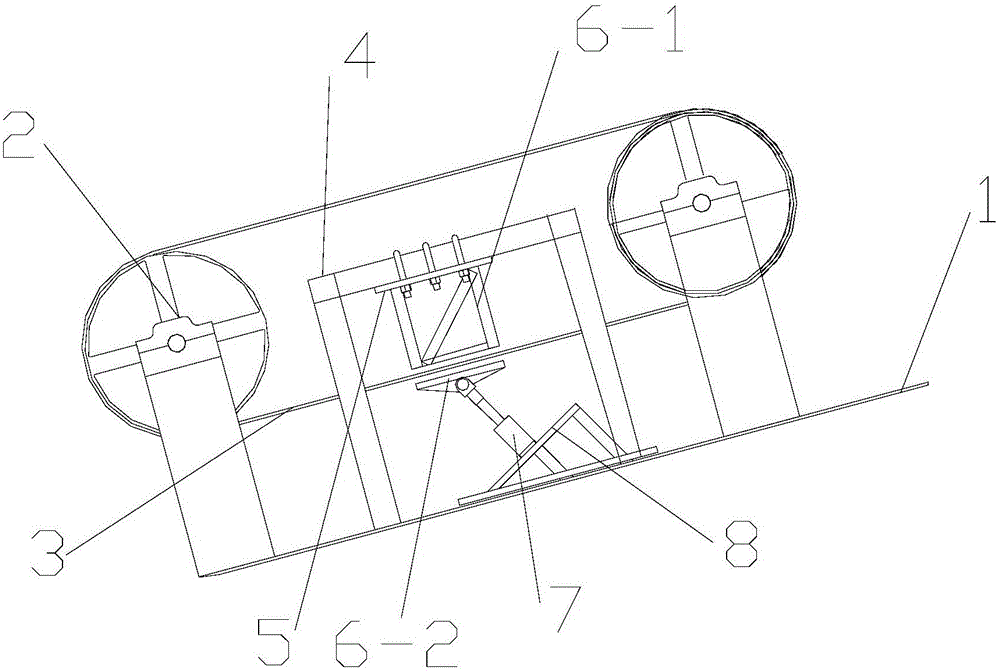

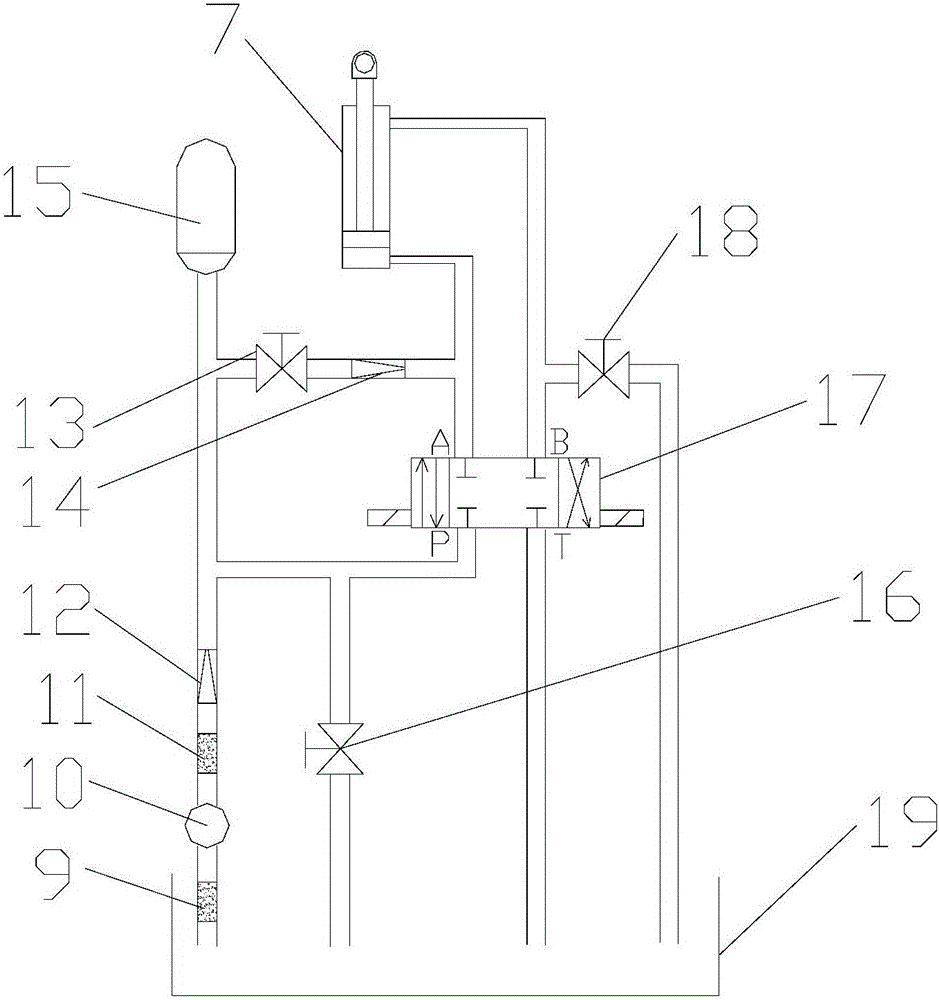

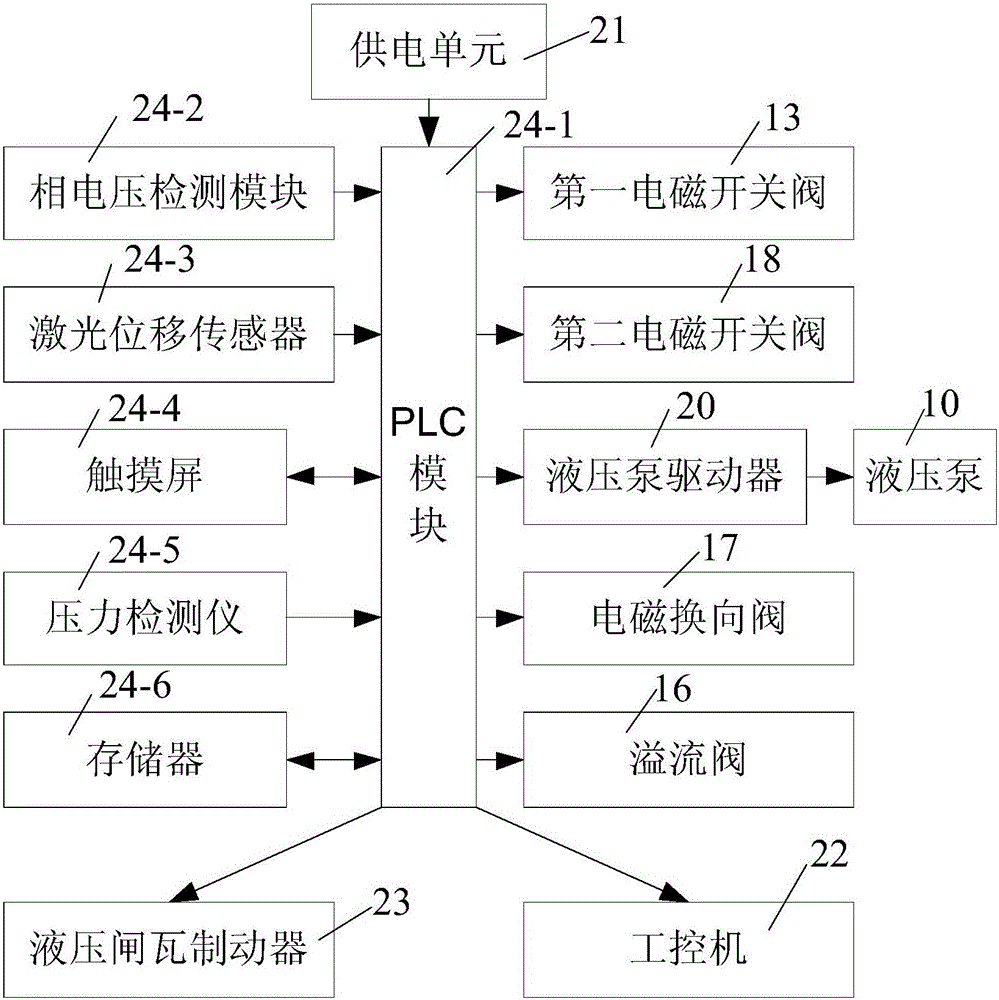

[0056] like figure 1 , figure 2 and image 3 As shown, the anti-running protection system of a down-moving belt conveyor according to the present invention includes a damping device for braking the operation of the belt conveyor 2 parallelly installed on the down-moving inclined surface 1, and is used to drive the damping device. The hydraulic execution subsystem for the action of the device and the control subsystem for real-time detection and control of the running state of the belt conveyor 2;

[0057] The damping device includes a mounting frame 4 installed on both sides of the belt conveyor 2 and a mounting plate 5 fixedly installed between the two mounting frames 4. The mounting plate 5 is arranged on the top belt and the bottom belt 3 of the belt conveyor 2 in parallel. Between, on the bottom surface of mounting plate 5, the upper damping device 6-1 that is parallel with bottom belt 3 is installed, the height of upper damping device 6-1 is less than the distance betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com