A kind of fruit and vegetable skin dregs compression molding equipment

A technology of compression molding and fruit and vegetable skins, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of waste of resources, a large number of by-products, economic losses, etc., to facilitate processing and manufacturing, improve service life, improve The effect of compression efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

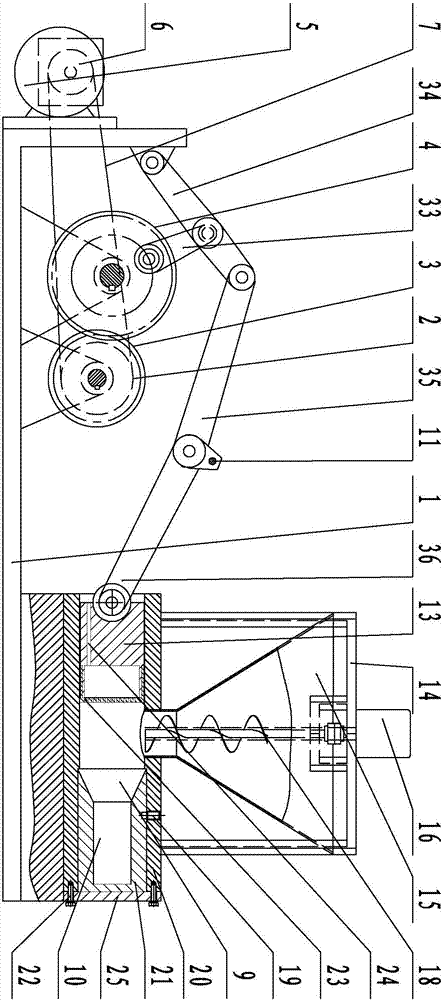

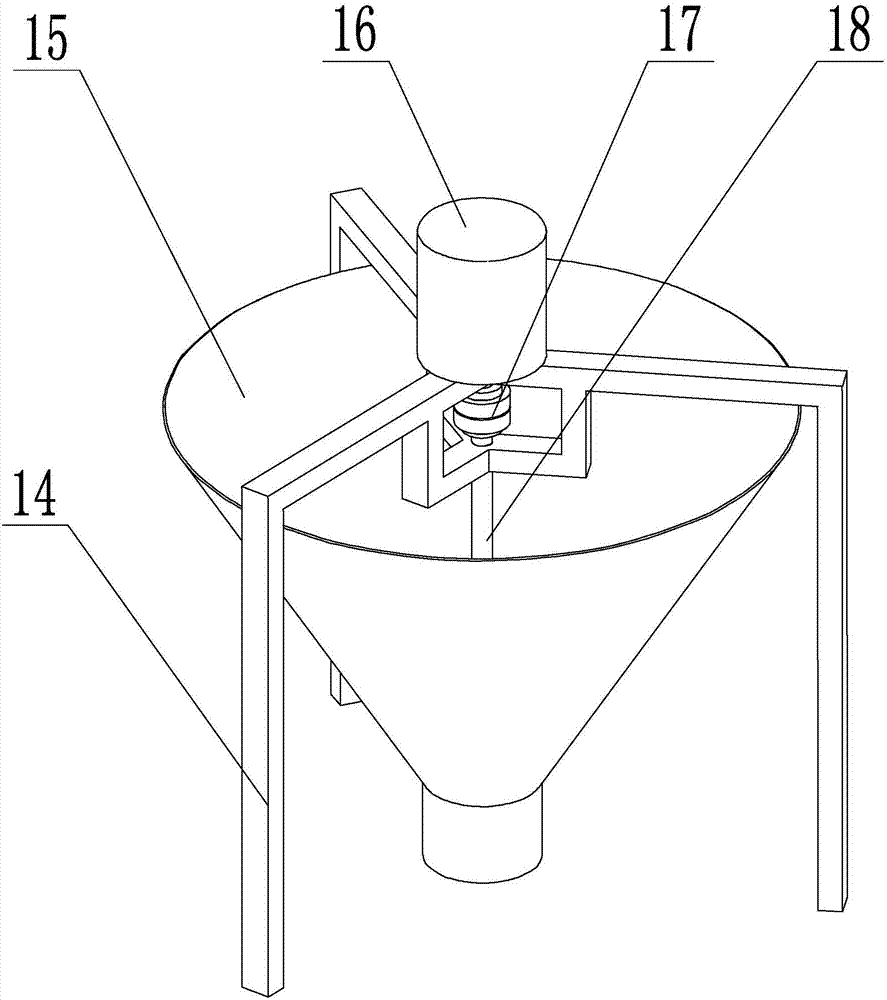

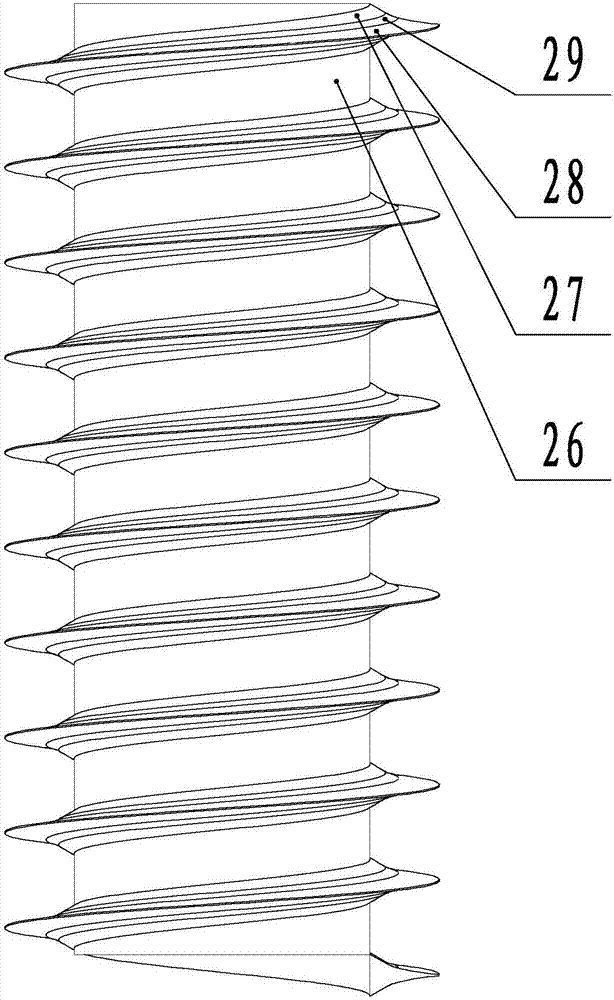

[0017] The present invention will be described in further detail below in conjunction with the embodiments given in the accompanying drawings.

[0018] refer to figure 1 , figure 2 , image 3 and Figure 4 As shown, a kind of fruit and vegetable dregs compression molding equipment of the present embodiment comprises a frame 1, a main motor 5, a speed reduction mechanism and a compression mechanism, the main motor 5 is fixedly installed on one side of the frame 1, and the speed reduction mechanism Installed on the frame 1 and connected with the main motor 5 through transmission, the compression mechanism is fixedly installed on the side of the frame 1 facing away from the deceleration mechanism and connected with the deceleration mechanism through transmission, characterized in that the deceleration mechanism includes a driving gear 3. The driven gear 4 and the connecting rod mechanism, the driving gear 3 is connected to the rotating shaft of the main motor 5, the driven ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com