A sand-shooting quantitative structure for automatic core shooting

A quantitative structure and automatic technology, which is applied in the direction of casting molding equipment, molding machine parts, metal processing equipment, etc., can solve the problems of sand leakage in the nozzle seal, split flow decompression, and false injection, so as to achieve dense sand shooting and avoid The effect of shunting and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

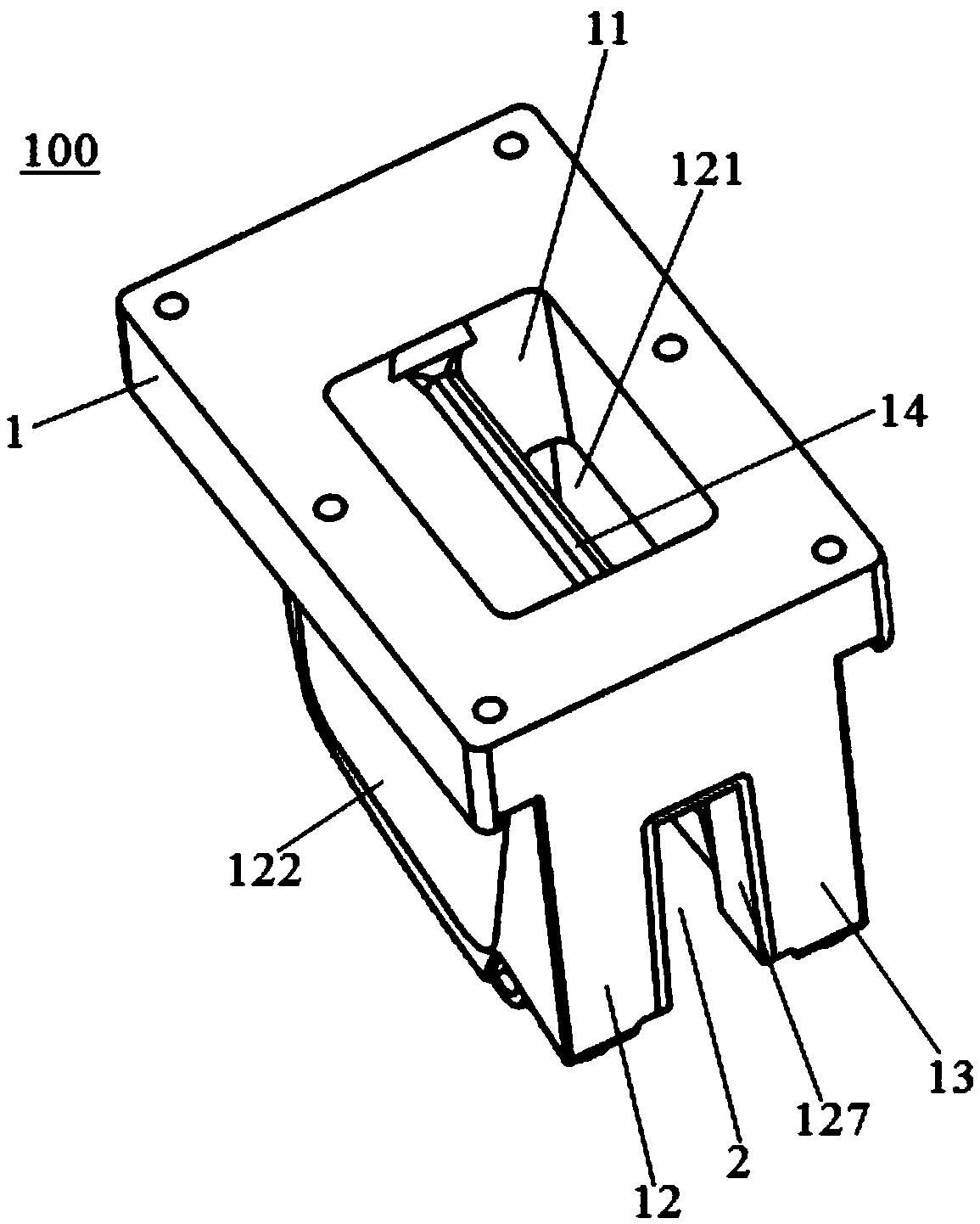

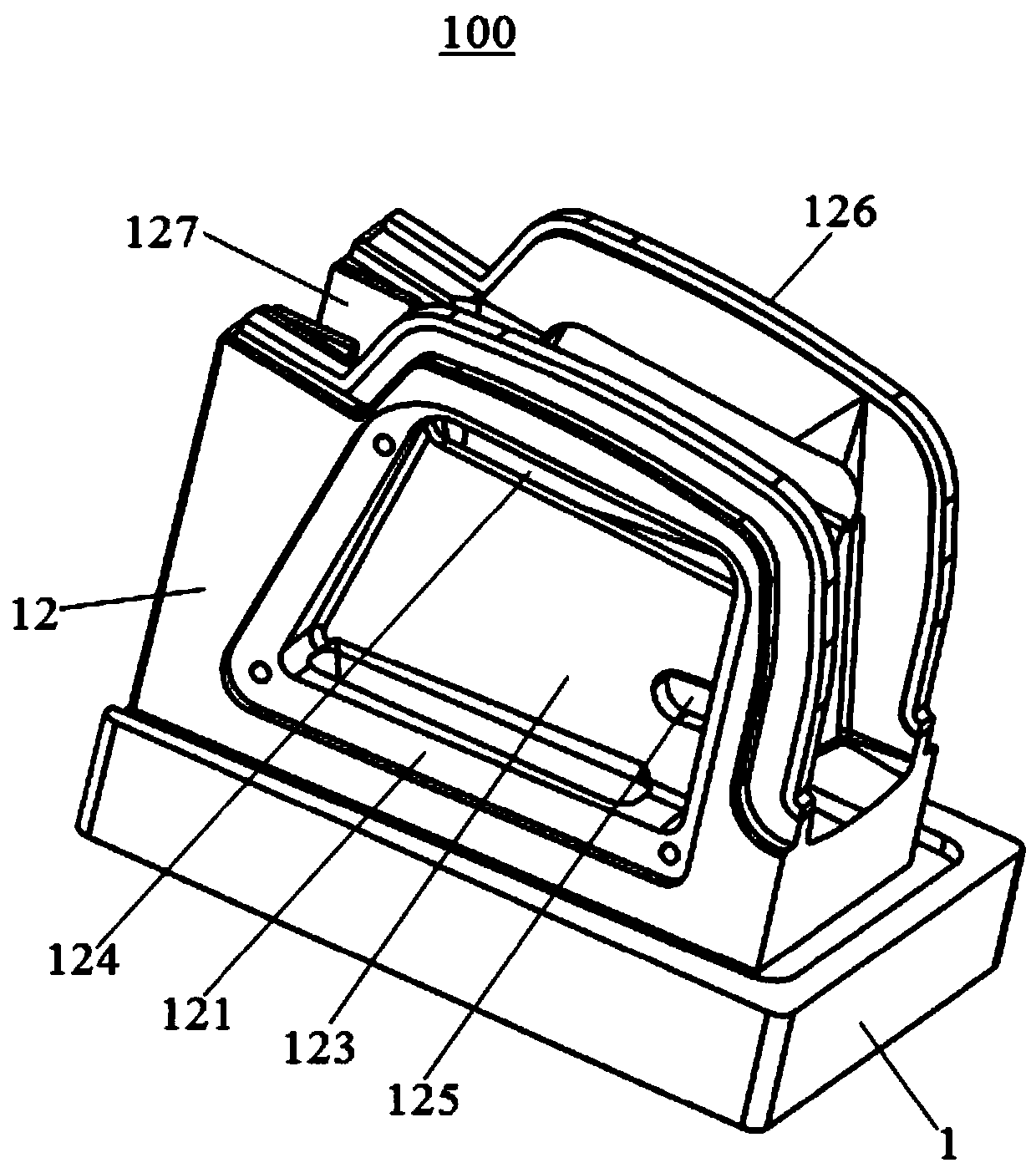

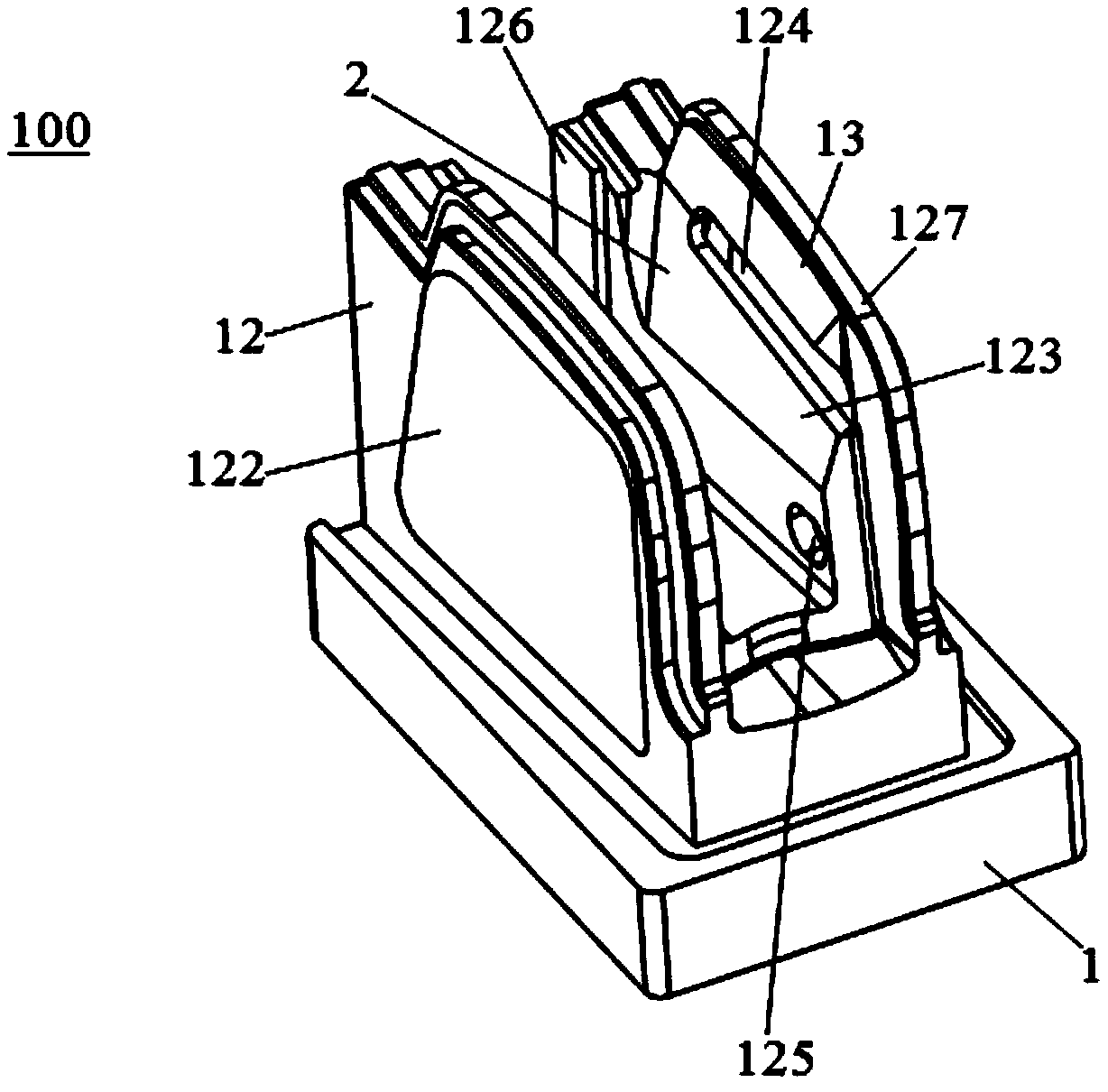

[0018] Please refer to Figure 1-Figure 3 , the present embodiment is a sand shooting quantitative structure 100 for automatic core shooting, which is mainly used in conjunction with sand molds. It includes a nozzle body 1 and a first cavity 2 formed by the cooperation of the nozzle body 1 and the sand mold.

[0019] The shot head body 1 includes a sand inlet 11 arranged on the upper surface, a first enclosure body 12 and a second enclosure body 13 which form the first cavity 2 and are oppositely arranged.

[0020] The first enclosure body 12 has the same structure as the second enclosure body 13, and includes a second cavity 121 which is hollow inside, a first sealing plate 122 which closes one side of the second cavity 121, and a second sealing plate 122 which closes the other side of the second cavity 121. The second sealing plate 123 on the surface. The second sealing plate 123 is provided with a main sand injection port 124 and a secondary sand injection port 125 communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com