Children formula milk containing OPO structure fat and preparation method of children formula milk

A technology for structural oils and children, applied in dairy products, whey, applications, etc., can solve the problems of not mentioning the addition of OPO structural lipids, no OPO structural lipids, high protein denaturation and sedimentation rate, and achieve stable and consistent nutrient content. , The effect of preventing oil agglomeration and floating, and nutrient composition stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

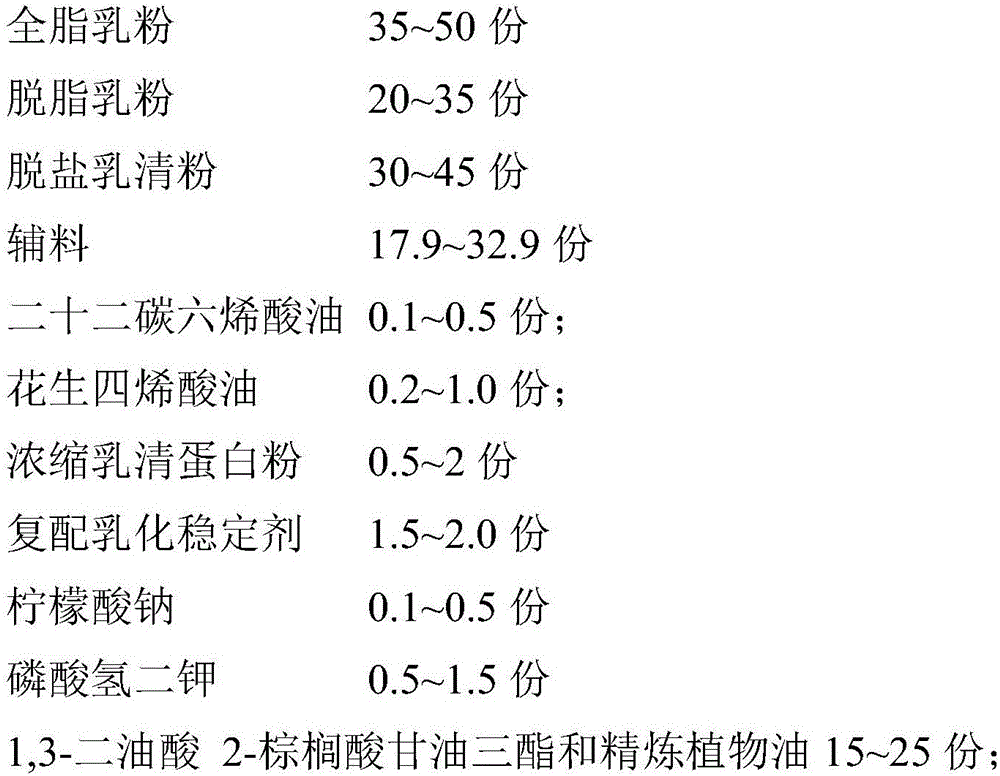

[0035] A child formula milk containing OPO structure oil, including:

[0036]

[0037] Among them, the refined vegetable oil is one or a combination of sunflower oil, rapeseed oil, soybean oil, and palm kernel oil; the compound nutrient contains vitamin A, D, taurine, iron, zinc and other nutrients.

[0038] In the prepared formula milk, the main characteristic indexes of the product are as follows:

[0039] Polyunsaturated fatty acid ≥0.23 / 100g;

[0040] 1,3-Dioleic acid 2-palmitic acid triglyceride 0.35~1.40g / 100g;

[0041] The content of palmitic acid in Sn-2 is ≥40%.

Embodiment 2

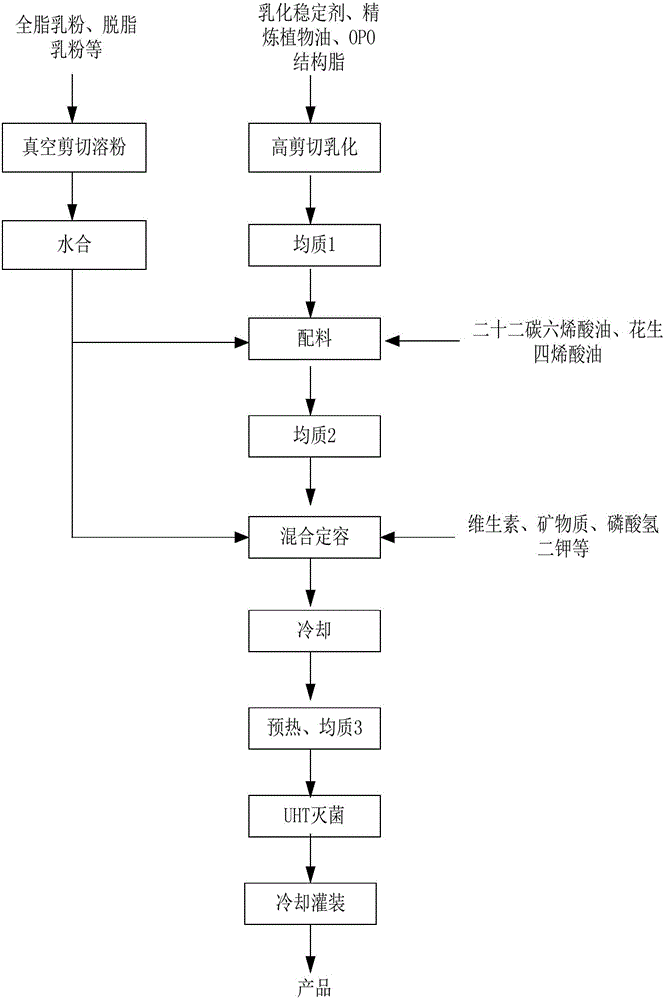

[0043] Such as figure 1 Shown is the preparation process flow chart. The preparation method of formula milk for children includes the following steps:

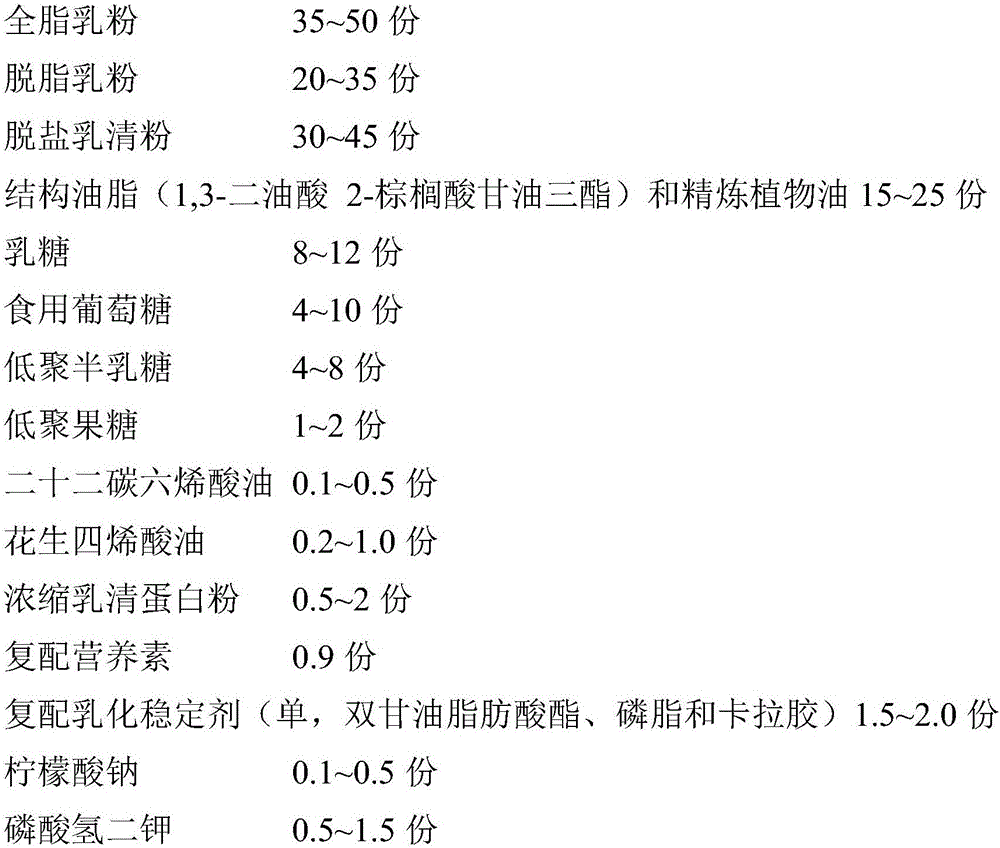

[0044] 1) Mix 30~45 parts of desalted whey powder, 20~35 parts of skimmed milk powder, 35~50 parts of whole milk powder, 0.5~2 parts of concentrated whey protein powder, 8~12 parts of lactose, 4~10 parts of edible glucose 1~2 parts, 1-2 parts of fructooligosaccharides, 4~8 parts of galacto-oligosaccharides, weighed according to the formula ratio and dissolved in purified water at 40~45℃ under vacuum high-speed shearing, control the concentration to about 20%, and cool to 4~6 Hydrate at ℃ for 15~24h to make hydrated milk;

[0045] 2) Pump the purified water at 50~60℃ into the batching tank, slowly put in the compound emulsion stabilizer, after shearing and circulating in the 2900r / m high-speed emulsification shearing tank for 10-15min, then add OPO structure oil and mix and refine Vegetable oil (sunflower seed oil, rapeseed oil, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com