One-time tunneling two-roadway-retained excavating operation production line

A production line and operation technology, which is applied to mining equipment, earthwork drilling, shaft lining, etc., can solve problems such as increased labor intensity of workers, roadway extrusion deformation, and reduction of roadway net section, so as to improve coal recovery rate, control deformation, The effect of improving the overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

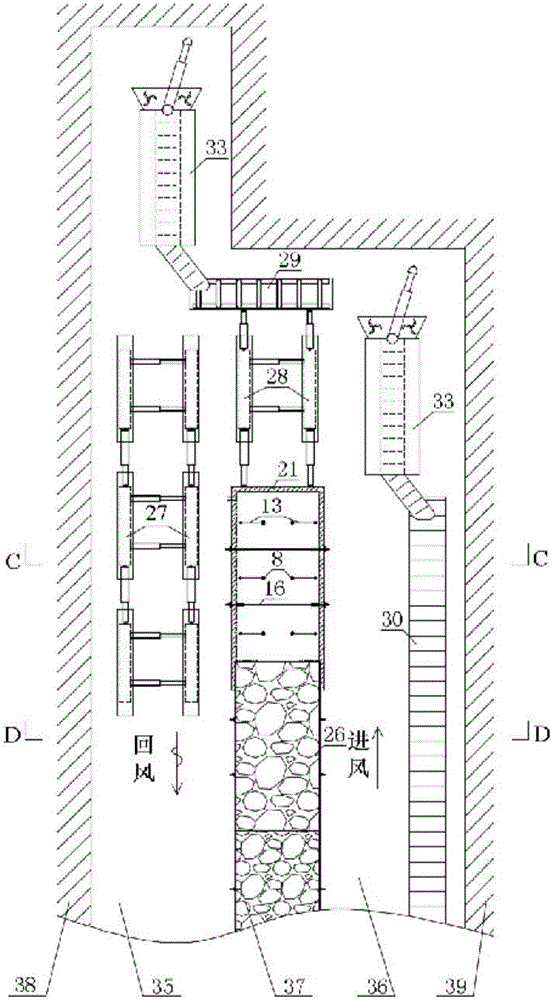

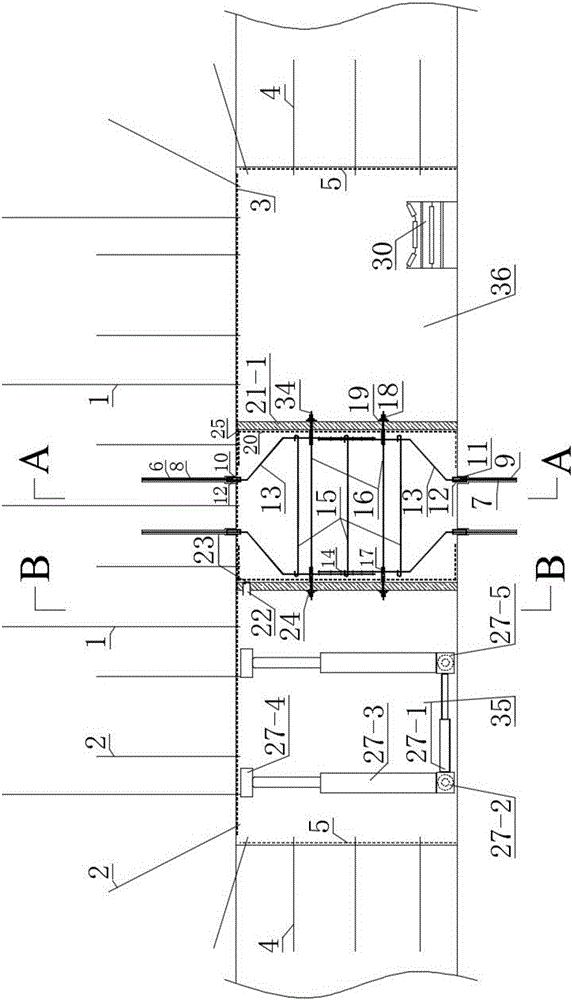

[0031]The setting of gob-side roadway for mining without coal pillars has to go through five stages: excavation of the roadway, stability of the roadway after excavation, influence of disturbance of backing pressure in advance of mining, peak value of backing pressure after mining, and recovery of post-mining pressure. In the U-shaped ventilation of the present invention, " The gob-side entry + middle partition wall + parallel channel” is used to set up double-entry and support methods in one excavation. The gob-side entry, the concrete artificial coal pillars beside the entry, and the mining trough are considered as a whole and excavated together. During the excavation along the tunnel, the gob-side entry is used as the sewage air tunnel during the excavation, and it is also used as the auxiliary transportation roadway adjacent to the tunnel during the mining period. In the coal mining stage of the next section, it is reserved as the gob-side entry and used as the mining tunnel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com