Method for producing gamma-aminobutyric acid by using recombinant Bacillus subtilis

A technology of Bacillus subtilis and aminobutyric acid, which is applied in the field of microbial catalytic production of γ-aminobutyric acid, which can solve the problems of low conversion rate, limited application of endotoxin removal, and acidic conditions required for conversion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] 1. Construction of recombinant Bacillus subtilis genetic engineering bacteria

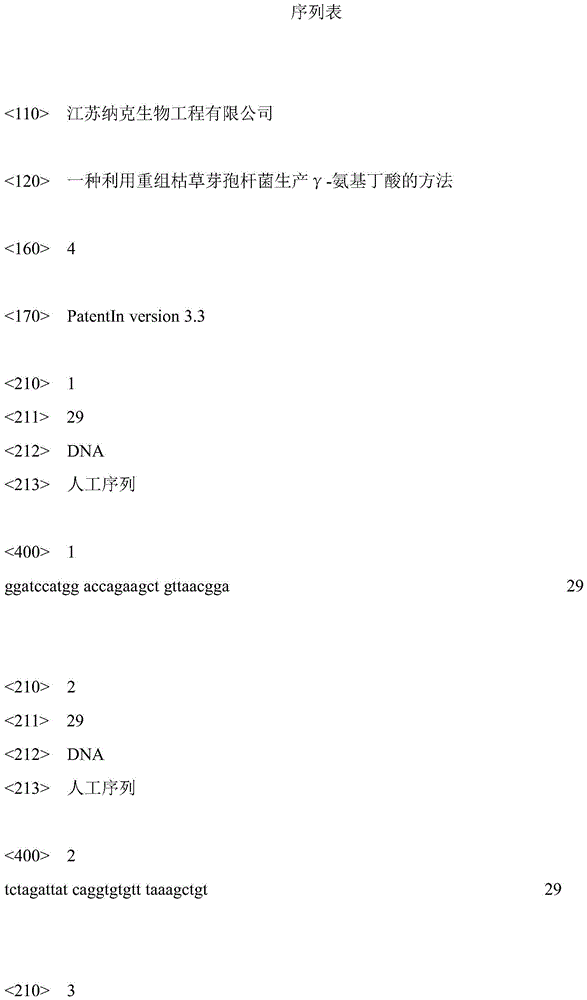

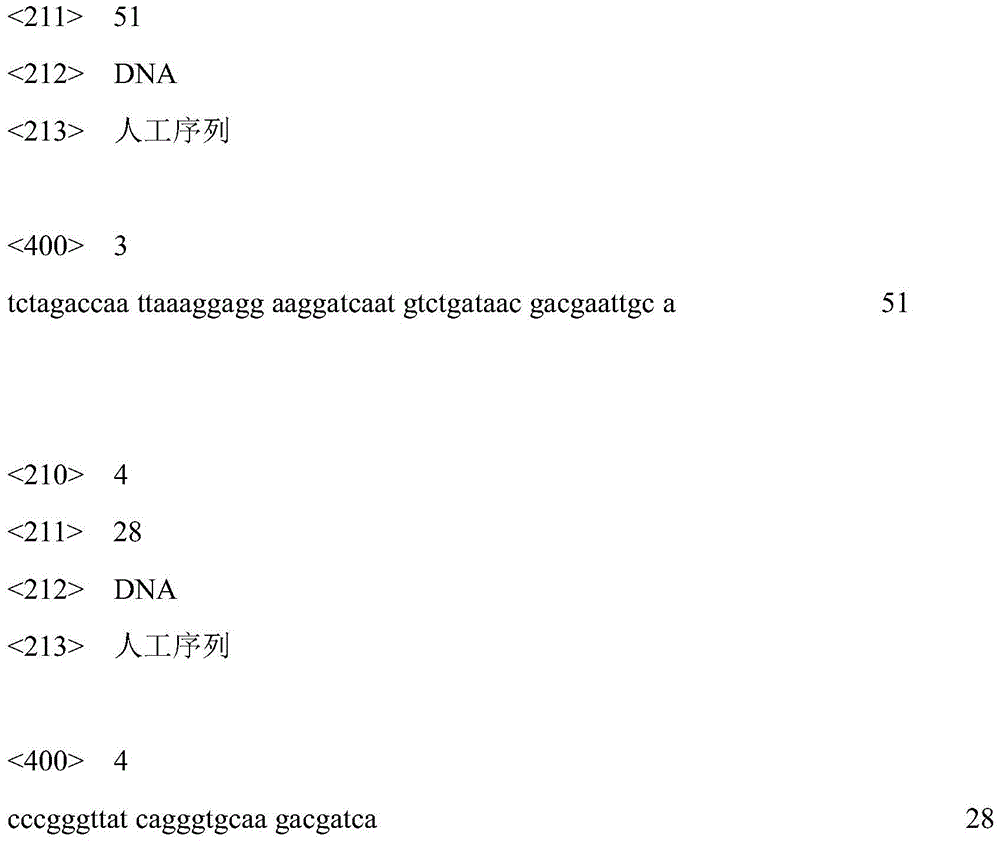

[0020] (1) Cloning of Escherichia coli gadA and pdxH genes

[0021] Genomic DNA of Escherichia coli DH5α was extracted using a bacterial genomic DNA extraction kit. Using the genomic DNA as a template, P1 and P2 as primers, PCR amplifies the gadA gene, and uses primers P3 and P4 as primers to amplify the pdxH gene. Using a PCR product recovery kit, purify the PCR amplified product gadA gene fragment and pdxH gene fragment. The purified PCR product was ligated with the pUCm-T vector, and the ligated reaction product was transformed into Escherichia coli DH5α. Spread the blue-white screening plate, select the white colony on the plate, extract the plasmid, carry out double enzyme digestion and identification of the plasmid, and screen to obtain the recombinant bacteria DH5α / pUCmT-gadA and DH5α / pUCmT-pdxH. Extract the plasmid and send it to Shanghai Sangon Bioengineering Co., Ltd. for sequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com