Powered coal conveyor belt washing equipment

A technology for cleaning devices and conveyor belts, which is applied in the direction of cleaning devices, conveyors, conveyor objects, etc., which can solve the problems of large space occupation, large circulating water volume, and poor cleaning effect, so as to ensure the scraping effect and reduce the installation accuracy requirements , keep clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

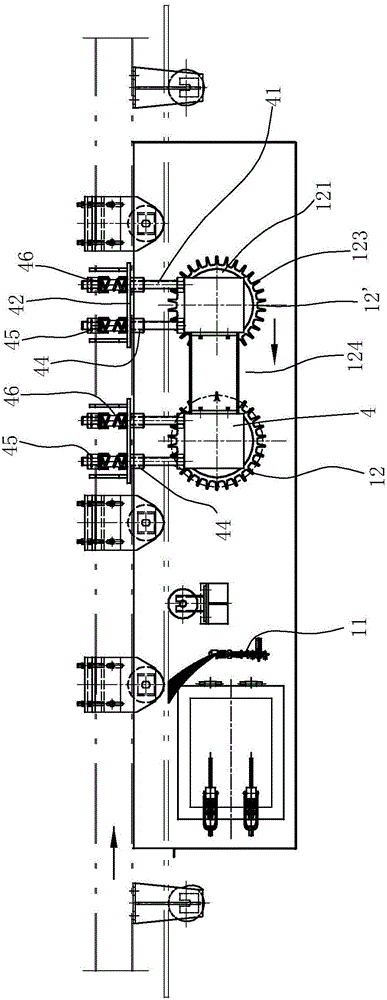

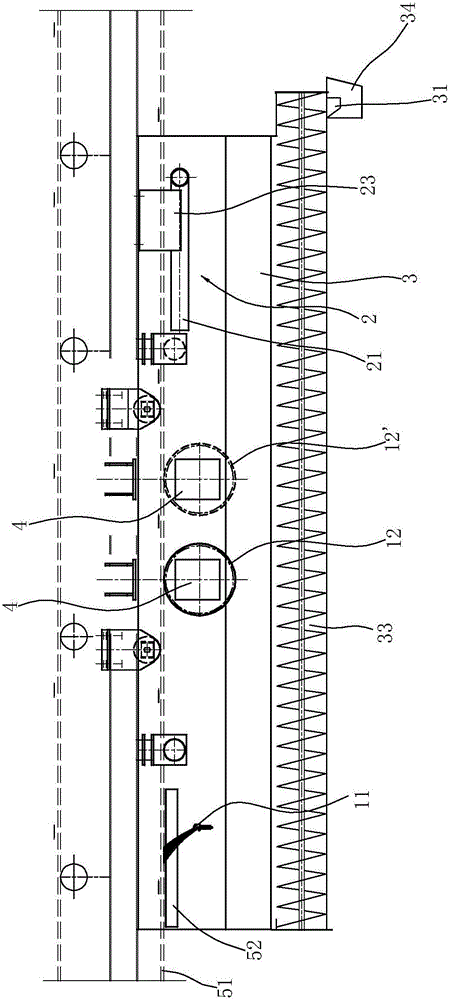

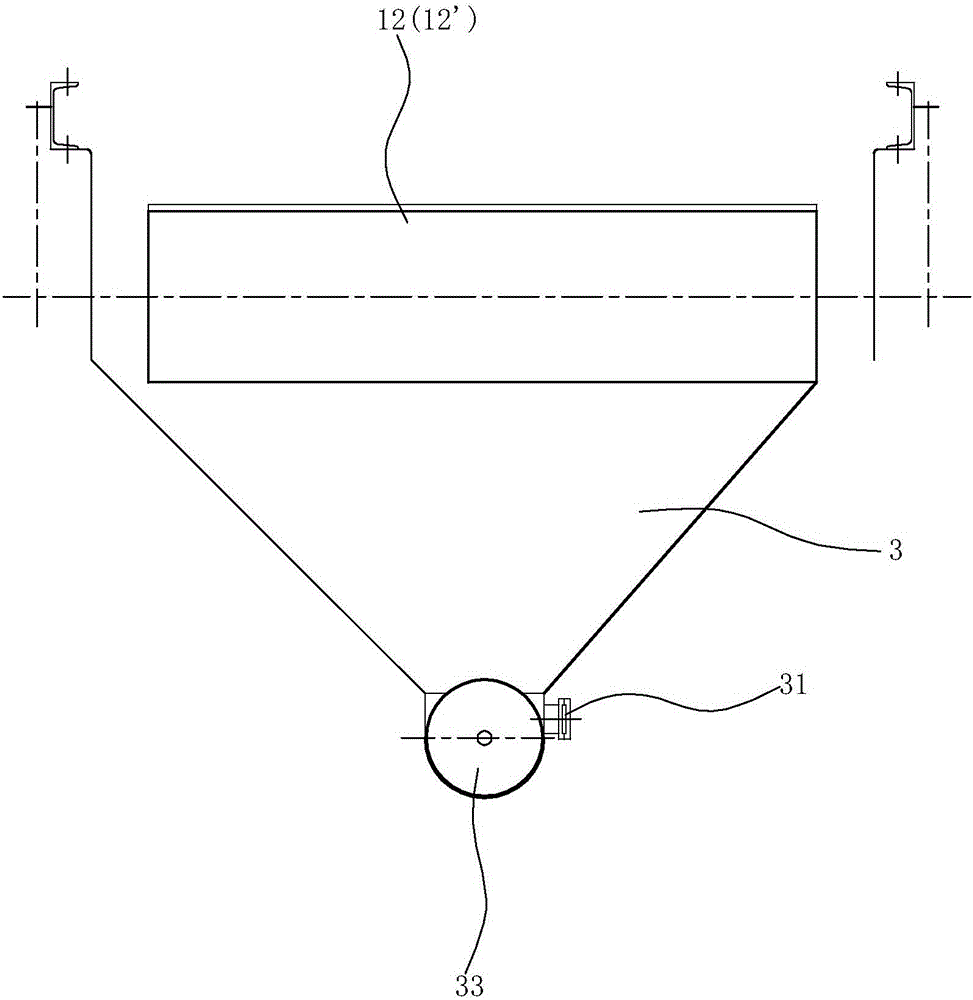

[0029] Such as Figure 1 to Figure 9 As shown, the pulverized coal conveyor belt cleaning device includes a cleaning device 1, a drying device 2 and a water tank 3 arranged below the return belt.

[0030] Wherein there are multiple groups of cleaning devices 1, which are arranged at intervals along the length direction of the return belt 51; the number of cleaning devices is related to the conveying distance of the belt conveyor and the conveying materials, and can be specifically determined according to actual conditions.

[0031] Each group of cleaning devices 1 sequentially includes a water spray head 11 and a mud scraping roller along the conveying direction of the belt. There are two mud scraping rollers in each group of cleaning devices, and the driving device 122 drives and connects the first mud scraping roller 12, and the first mud s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com