Compressor system and method for operating the compressor system in dependence on the operating state of the rail vehicle

A technology for compressor systems and rail vehicles, applied to the operating mechanism of railway vehicle brakes, the arrangement of pumps/compressors, components of pumping devices for elastic fluids, etc., which can solve problems such as noise emissions and achieve energy reduction Consumption, reduced cooling requirements, and slower running effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

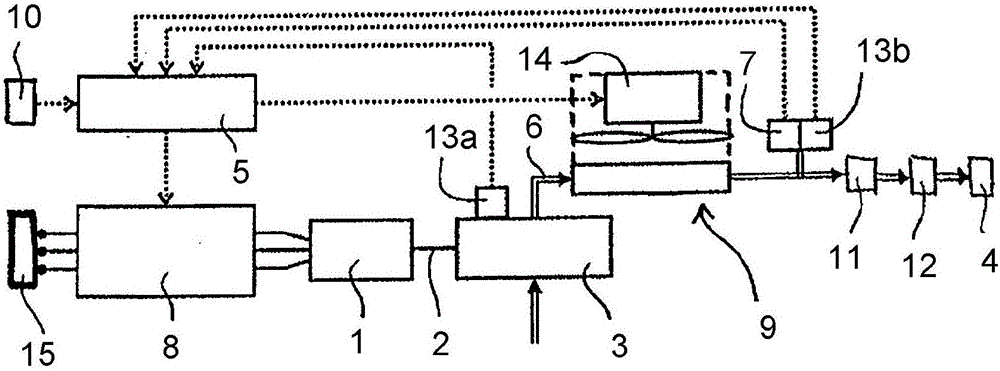

[0022] according to figure 1 , a compressor system for a rail vehicle has an electric motor 1 , which drives a compressor 3 for generating compressed air via a drive shaft 2 . The compressed air produced by the compressor 3 is conveyed via the compressed air duct 6 to the cooling unit 9 with the cooling fan 14 . Downstream of the cooling unit 9 , a pressure sensor 7 and a temperature sensor 13 b are arranged in the compressed air guide line 6 . Furthermore, the compressed air line 6 leads into a pre-separator 11 , after which (downstream) an air treatment unit 12 is connected. The compressed air that has been dried and freed of particles is then fed into the compressed air container 4 . The temperature sensor 13 a arranged on the compressor 3 as well as the temperature sensor 13 b and the pressure sensor 7 all transmit the measured temperature and the measured pressure to the regulating device 5 . In addition, the regulating device 5 also receives signals from the train man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com