Preparation method and application of metal-doped spinel structure fast ion conductor coated nickel-containing positive electrode material

A technology of spinel structure and metal doping, applied in the preparation of lithium-ion batteries, preparation of metal-doped spinel structure fast ion conductors coated with nickel-containing positive electrode materials, field of modified lithium-ion battery positive electrode materials , can solve the problems of high cost, complex operation of fast ion conductors, and difficulty in industrial production, and achieve the effect of preventing dissolution loss, facilitating large-scale industrial production, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

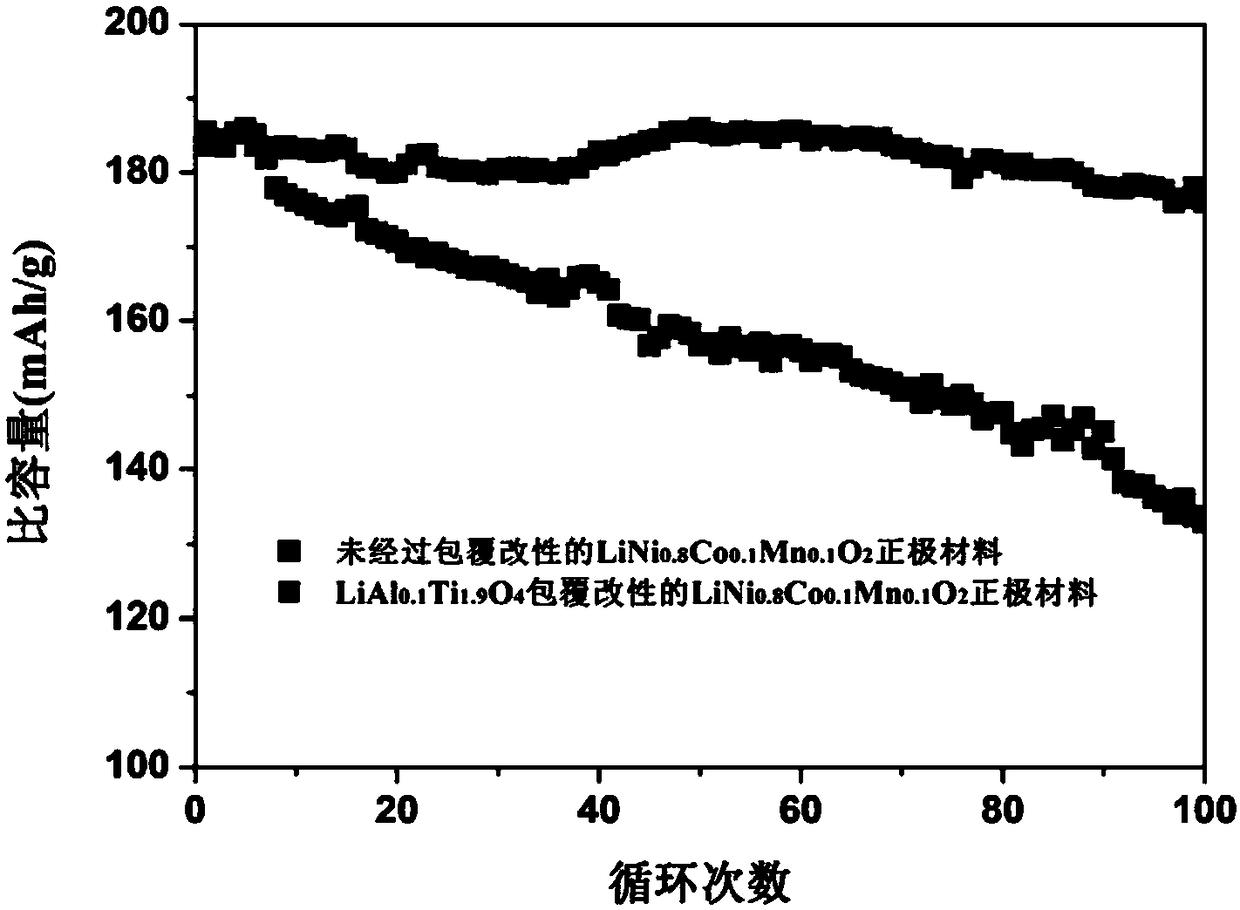

[0037] (1) According to LiAl 0.1 Ti 1.9 O 4 The coating mass percentage of the fast ion conductor relative to the positive electrode material is 0.5%. A quantitative amount of titanium isopropoxide is fully dispersed in anhydrous ethanol for 0.5 h using a mechanical stirring method or an ultrasonic method.

[0038] (2) The titanium isopropoxide dispersion in step (1) is heated in a water bath at 80°C, and the layered LiNi 0.8 Co 0.1 Mn 0.1 O 2 The positive electrode material was added to the titanium isopropoxide dispersion, and stirred and dispersed for 0.5 h.

[0039] (3) Dissolve the aluminum-containing metal salt in deionized water according to 1.4% of the atomic percentage of the doped metal element in the fast ion conductor, and add it to the titanium isopropoxide dispersion in step (2), and Continue stirring for 1.0h.

[0040] (4) Add the mixture obtained in step (3) to the reaction kettle, keep it at 80°C for 24h in a blast drying box, cool to room temperature naturally, wash...

Embodiment 2

[0048] (1) According to LiCe 0.05 Ti 1.95 O 4 The coating mass percentage of the fast ion conductor relative to the positive electrode material is 1.5%. A quantitative amount of titanium isopropoxide is fully dispersed in anhydrous ethanol for 0.2h by mechanical stirring method or ultrasonic method.

[0049] (2) The titanium isopropoxide dispersion in step (1) is heated in a water bath at 50°C, and the layered LiNi 0.85 Co 0.05 Mn 0.1 O 2 The positive electrode material was added to the titanium isopropoxide dispersion, and stirred and dispersed for 0.8 h.

[0050] (3) The cerium-containing metal salt is dissolved in deionized water according to 0.7% of the atomic percentage of the fast ion conductor occupied by the doped metal element, and added to the titanium isopropoxide dispersion in step (2), and Continue to stir for 1.5h.

[0051] (4) Add the mixture obtained in step (3) to the reaction kettle, keep it at 120°C for 48h in a blast drying box, cool it naturally to room temperatu...

Embodiment 3

[0056] (1) According to LiV 0.15 Ti 1.85 O 4 The coating mass percentage of the fast ion conductor relative to the positive electrode material is 2.0%. A quantitative amount of titanium isopropoxide is fully dispersed in absolute ethanol for 1.5 hours by mechanical stirring method or ultrasonic method.

[0057] (2) The titanium isopropoxide dispersion in step (1) is heated in a water bath at 50°C, and the layered LiNi 0.5 Co 0.2 Mn 0.3 O 2 The positive electrode material was added to the titanium isopropoxide dispersion, and stirred and dispersed for 4.0 h.

[0058] (3) The vanadium-containing metal salt is dissolved in deionized water according to 2.0% of the atomic percentage of the fast ion conductor occupied by the doped metal element, and added to the titanium isopropoxide dispersion in step (2), and Continue stirring for 1.0h.

[0059] (4) Add the mixture obtained in step (3) to the reaction kettle, keep it at 140°C for 36 hours in a blast drying box, cool it naturally to room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com