A chain type crystal silicon texturing equipment and preparation method

A crystalline silicon and chain-type technology, which is applied in the field of chain-type crystalline silicon texturing equipment and preparation, can solve the problem of single purpose of texturing equipment, and achieve the effect of single purpose, simple process and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

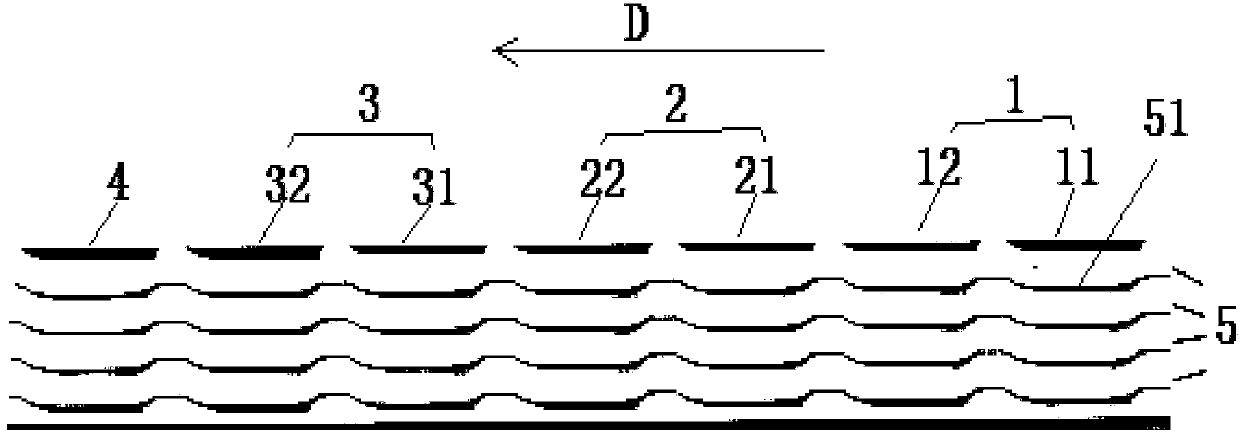

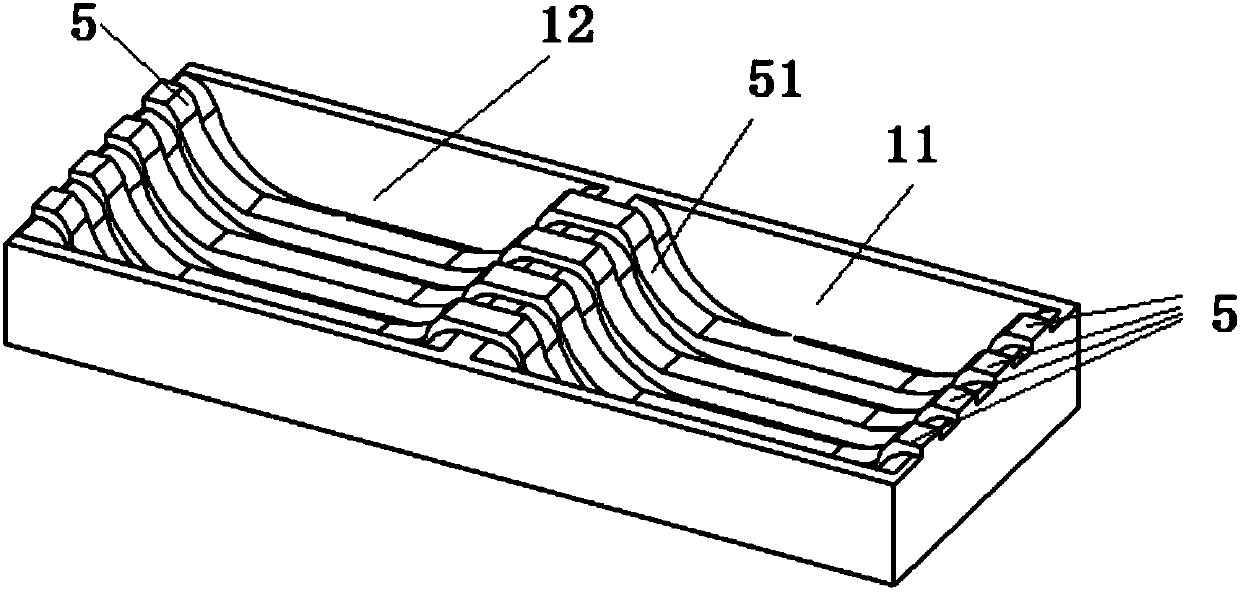

[0026] figure 1 It is a structural schematic diagram of a chain type crystal silicon texturing equipment according to an embodiment of the present invention. Such as figure 1 As shown, a chain-type crystal silicon texturing equipment of the present invention includes texturing tanks 1, cleaning tanks 2, post-processing tanks 3, drying tanks 4 and In the chain drive system 5 of transmission flower basket (not shown in the figure), described flower basket (not shown in the figure) is used for loading silicon chip, and described chain drive system comprises described texturing tank 1, cleaning tank 2 , the independent transmission device 51 that each tank body in post-processing tank 3 and drying tank 4 is all provided with, wherein the operation direction D of crystal silicon is the movement or motion direction of crystal silicon on the texturing process line, each tank There is an interval between the tanks to ensure that the solutions between adjacent tanks are separated; th...

Embodiment 2

[0044] In another specific implementation manner, the parts that are the same as those in Embodiment 1 will not be repeated here, and only the different parts will be described.

[0045] For polysilicon texturing, during the texturing process, the acidic texturing liquid is added to the texturing process tank 11, and the temperature is lowered to a predetermined temperature, and the flower basket loaded with a predetermined number of silicon wafers is transferred to the texturing liquid through a transmission device, and the crystals are reacted for a certain period of time. The silicon surface gets a textured texture of worms. The textured silicon wafers are transported to the first water tank 12 to remove the acidic solution on the surface of the crystalline silicon through the flower basket. Among them, the texturing process tank 11 also includes a texturing liquid delivery device, which has an automatic liquid replenishment function according to the batch of reaction, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com