A pulse power capacitor

A pulsed power, capacitor technology, applied in the field of capacitors, can solve problems such as low reliability and safety, capacitor cracks, expansion breakdown, etc., to achieve high reliability and safety, prevent expansion breakdown, and increase welding ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

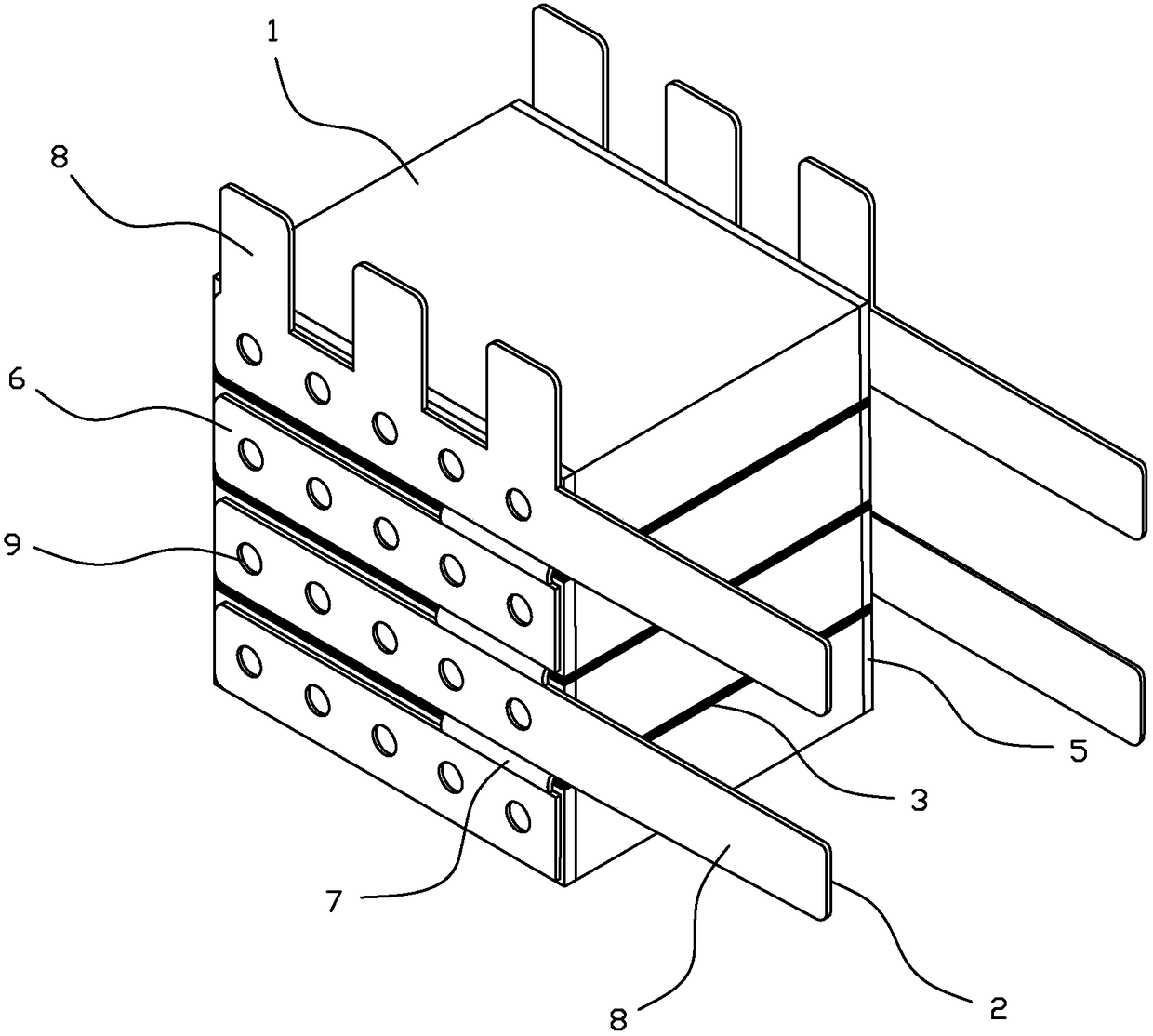

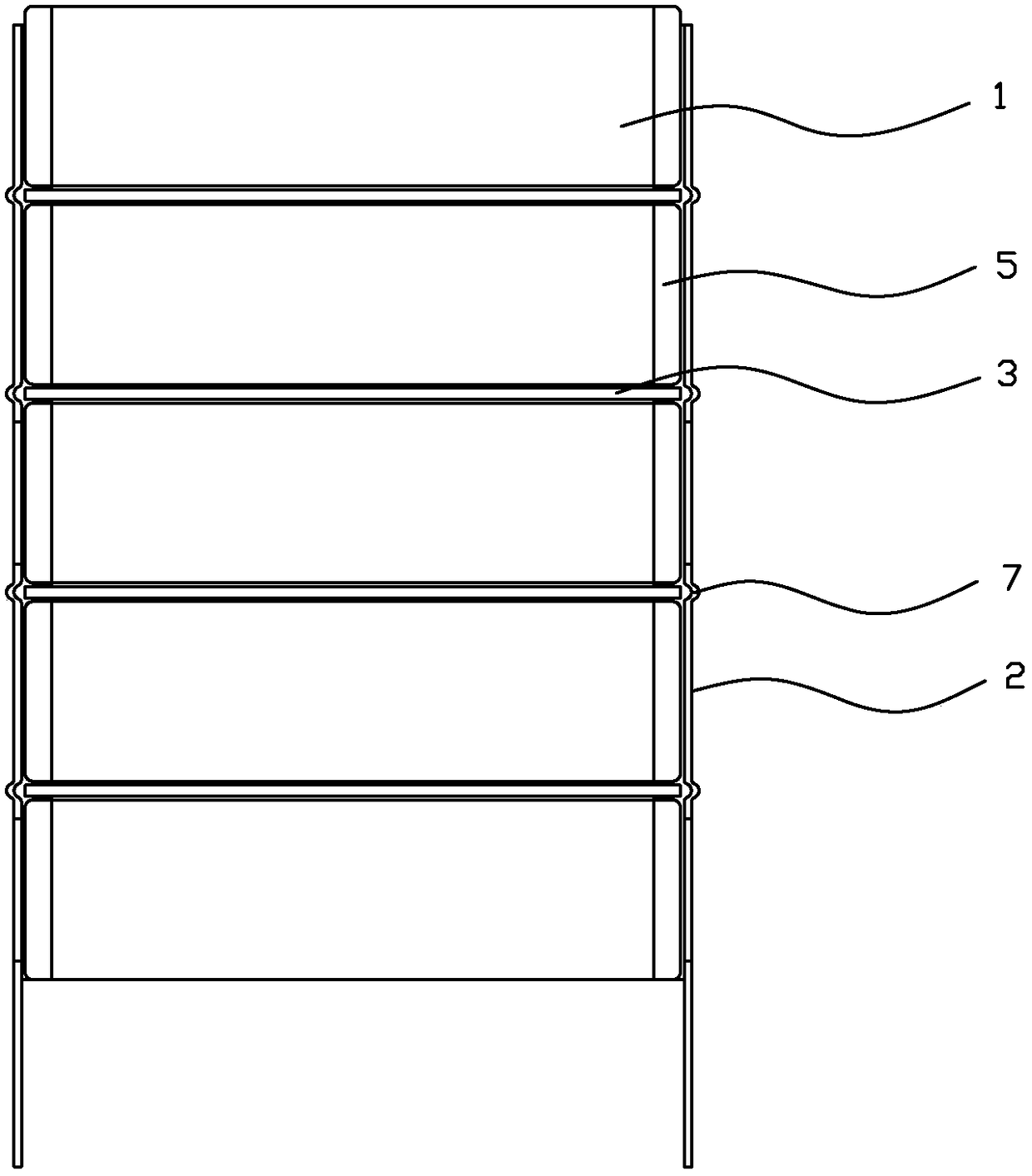

[0035] refer to Figure 1 to Figure 7 A pulse power capacitor of the present invention includes four capacitors 1 and two metal electrode sheets 2, and the four capacitors 1 are stacked and connected in parallel through the two metal electrode sheets 2 to form a parallel capacitor bank. A buffer pad 3 is arranged between two adjacent capacitors 1 , and the buffer pad 3 is made of polytetrafluoroethylene plastic sheet, and is bonded between two adjacent capacitors 1 by red glue 4 . The metal electrode sheet 2 is formed with four electrode plates 6 respectively used to connect the electrodes 5 of the four capacitors 1, the four electrode plates 6 are connected as a whole through the expansion joints 7 connected between two adjacent electrode plates 6, and Several pins 8 are drawn out from the edge of the metal electrode sheet 2 . The electrodes 5 on both sides of the capacitor 1 are respectively welded to the electrode plates 6 of the two metal electrode sheets 2 .

[0036] Th...

Embodiment 2

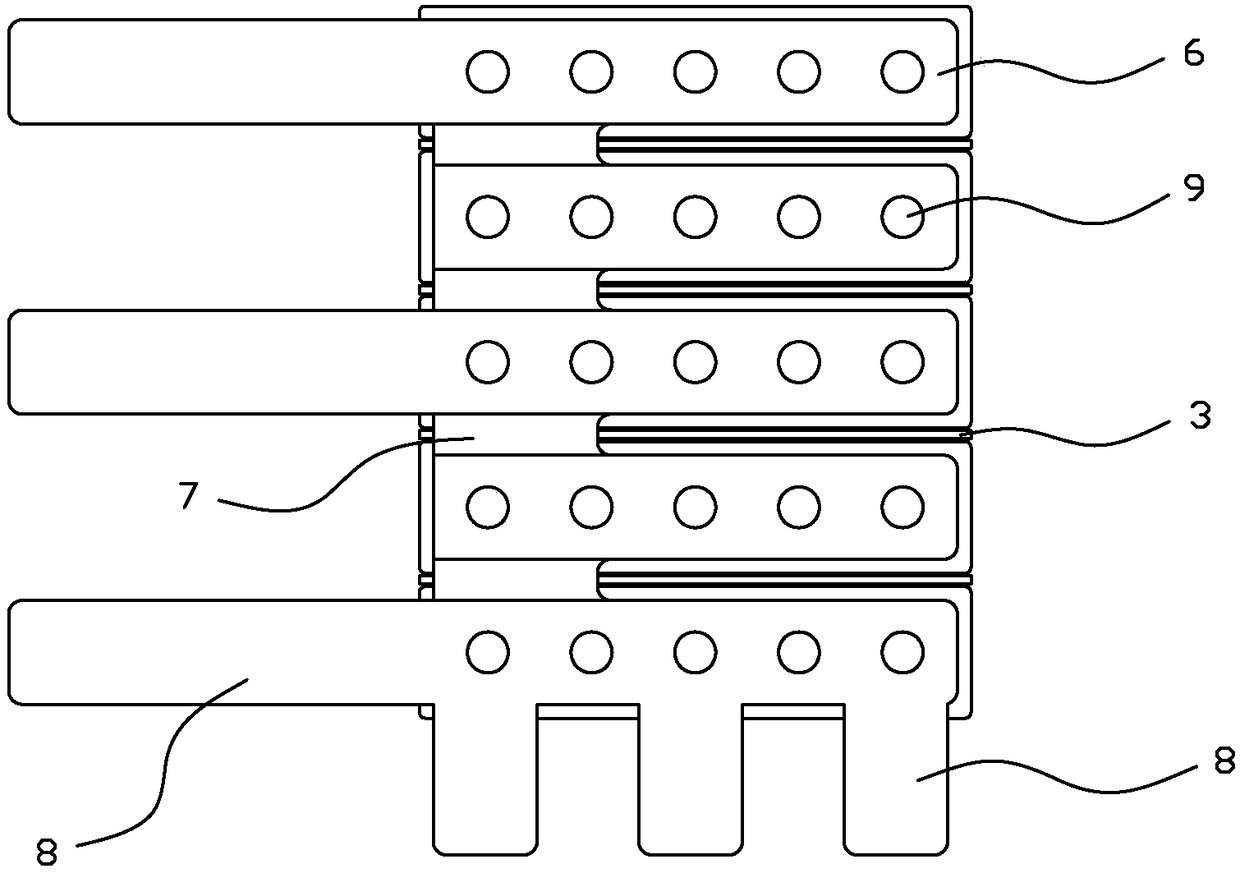

[0039] refer to Figure 8 and Figure 9 The difference between this embodiment and Embodiment 1 is that a pulse power capacitor in this embodiment includes two capacitors 1 and two metal electrode sheets 2, and the two capacitors 1 are stacked and connected in parallel through two metal electrode sheets 2 to form a parallel connection. capacitor bank. The metal electrode sheet 2 is formed with two electrode plates 6 respectively used to connect the electrodes 5 of the two capacitors 1 , and the two electrode plates 6 are connected as a whole through an expansion joint 7 connected between the two electrode plates 6 . One pin 8 is formed on the side of the metal electrode sheet 2 and three pins 8 are formed on the bottom.

Embodiment 3

[0041] refer to Figure 10 and Figure 11 The difference between this embodiment and Embodiment 1 is that a pulse power capacitor in this embodiment includes five capacitors 1 and two metal electrode sheets 2, and five capacitors 1 are stacked and formed by connecting two metal electrode sheets 2 in parallel. Parallel capacitor bank. The metal electrode sheet 2 is formed with five electrode plates 6 respectively used to connect the electrodes 5 of five capacitors 1 , and the five electrode plates 6 are connected as a whole through expansion joints 7 connected between two adjacent electrode plates 6 . Three pins 8 are formed on the side of the metal electrode sheet 2 , and three pins 8 are formed on the bottom.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com