High-pressure electrolysis water control system and control method thereof

A high-voltage electrolysis and water control technology, applied in electrolysis components, electrolysis process, cells, etc., can solve problems such as poor control of power supply voltage, unsuitable for industrial production, danger, etc., to improve safety, increase safety, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

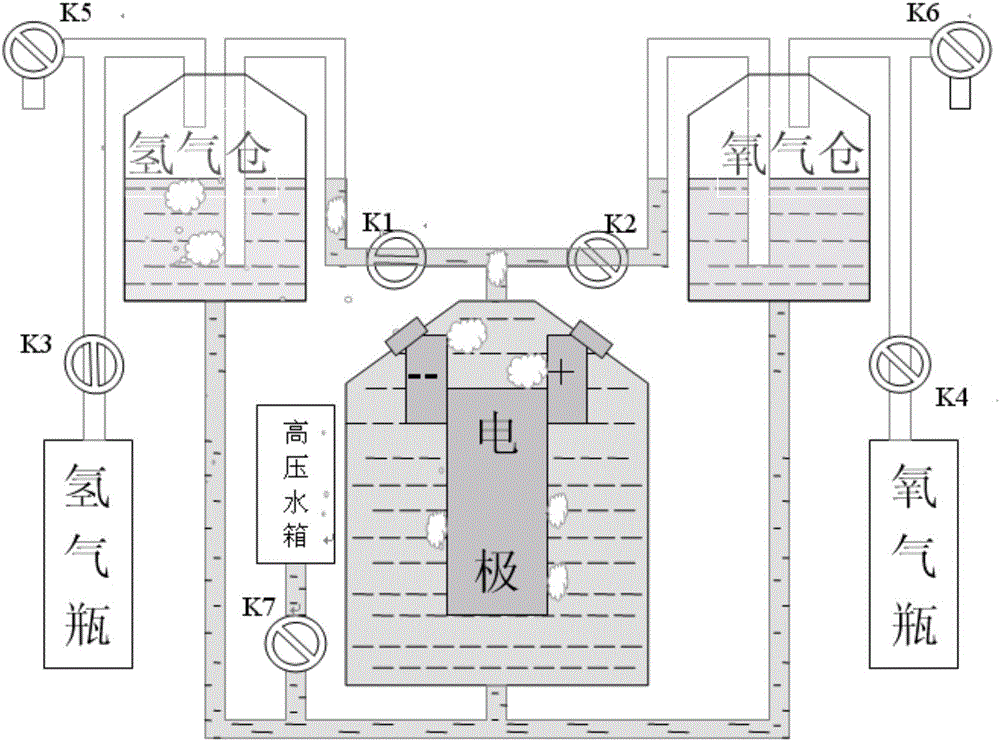

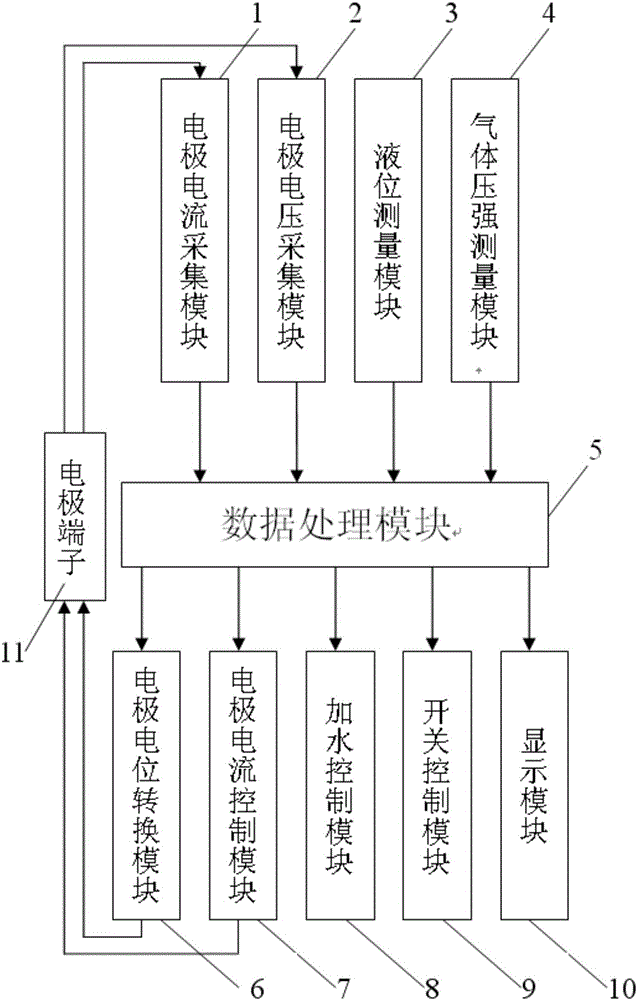

[0042] Below in conjunction with accompanying drawing, the present invention will be further described:

[0043] Such as figure 2 As shown, a high-voltage electrolyzed water control system includes an electrode current acquisition module 1, an electrode voltage acquisition module 2, a liquid level measurement module 3, a gas pressure measurement module 4, a data processing module 5, an electrode potential conversion module 6, and an electrode current control module. Module 7, water adding control module 8, switch control module 9, display module 10 and electrode terminal 11; The input end of described data processing module 5 is respectively connected with electrode current acquisition module 1, electrode voltage acquisition module 2, liquid level through data line The measurement module 3 and the gas pressure measurement module 4 are connected, and the output ends are respectively connected with the electrode potential conversion module 6, the electrode current control modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com