Preparation method of copper ion chelated nano particle biological coating

A nanoparticle and bio-coating technology, applied in coatings, polyamide coatings, hyaluronic acid coatings, etc., can solve problems such as poor blood compatibility, achieve remarkable results, low process cost, simple construction process and fixing method easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

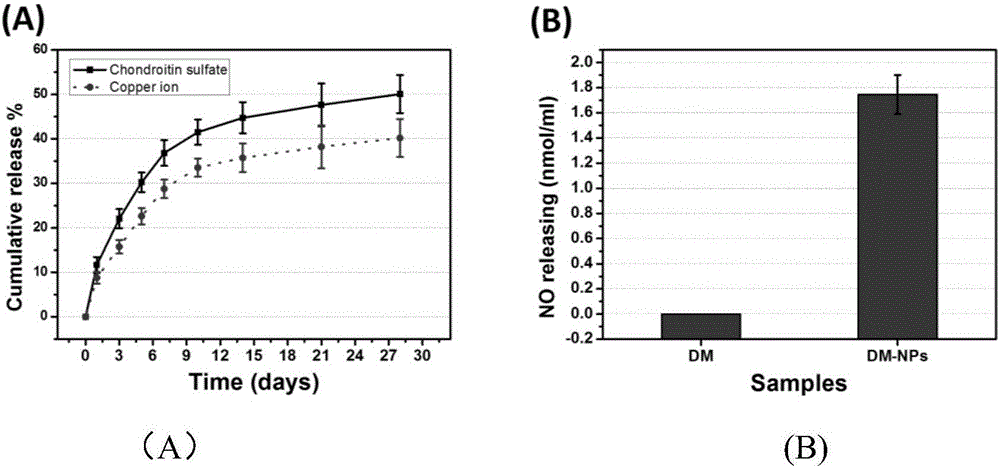

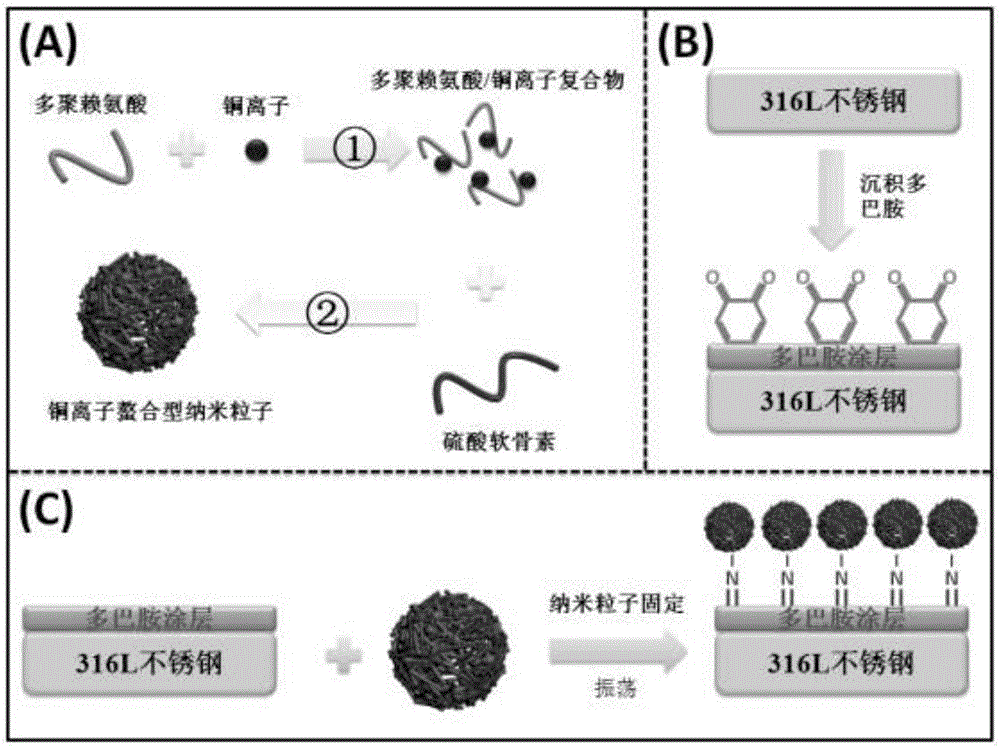

[0025] see figure 1 , the first specific embodiment of the present invention is, a kind of preparation method of copper ion chelating nanoparticle biological coating, and its steps are:

[0026] A, preparation of copper ion chelated nanoparticles: CuCl with a concentration of 0.1mM 2 The aqueous solution was mixed with a polylysine (PLL, molecular weight 150-300 KDa) solution with a concentration of 2.0 mg / ml in equal volumes, and allowed to stand at room temperature for 1 hour. Then the above-mentioned composite liquid is mixed with the chondroitin sulfate solution whose concentration is 10 mg / ml in equal volumes to obtain copper ion chelated nanoparticles;

[0027] B. Deposition of polydopamine coating: Deposit polydopamine coating on the surface of 316L medical stainless steel, and heat treatment at 60°C for 12 hours; on the one hand, dry the sample, and on the other hand, accelerate the conversion of phenolic hydroxyl group to quinone group in the dopamine coating transf...

Embodiment 2

[0030] A preparation method of a copper ion chelating nanoparticle biological coating, the steps of which are:

[0031] A, preparation of copper ion chelated nanoparticles: CuCl with a concentration of 10.0mM 2 The aqueous solution was mixed with a polylysine (PLL, molecular weight 150-300KDa) solution with a concentration of 5.0 mg / ml in equal volumes, and allowed to stand at room temperature for 3 hours. Then the above-mentioned composite solution is mixed with the chondroitin sulfate solution whose concentration is 50 mg / ml in equal volumes to obtain copper ion chelated nanoparticles;

[0032] B. Deposition of polydopamine coating: deposit polydopamine coating on the surface of 316L medical stainless steel, and heat treatment at 60°C for 12 hours;

[0033] C. Preparation of nanoparticle biological coating: Soak the sample deposited with polydopamine coating in step B in the nanoparticle suspension obtained in step A, shake and react at 40°C for 6 hours, rinse with double d...

Embodiment 3

[0035] A preparation method of a copper ion chelating nanoparticle biological coating, the steps of which are:

[0036] A, the preparation of copper ion chelating type nanoparticle: the CuCl that concentration is 5mM Aqueous solution and the polylysine (PLL, molecular weight 150-300KDa) solution equivolume mixing that concentration is 3.0mg / ml, leave standstill under room temperature 2 Hour. Then the above-mentioned composite liquid is mixed with the chondroitin sulfate solution whose concentration is 25 mg / ml in equal volumes to obtain copper ion chelated nanoparticles;

[0037] B. Deposition of polydopamine coating: deposit polydopamine coating on the surface of 316L medical stainless steel, and heat treatment at 60°C for 12 hours;

[0038] C. Preparation of nanoparticle biological coating: Soak the sample deposited with polydopamine coating in step B in the nanoparticle suspension obtained in step A, shake and react at 30°C for 12 hours, and rinse with double distilled wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com