A kind of preparation method of aryl boric acid catechol ester modified phenolic resin

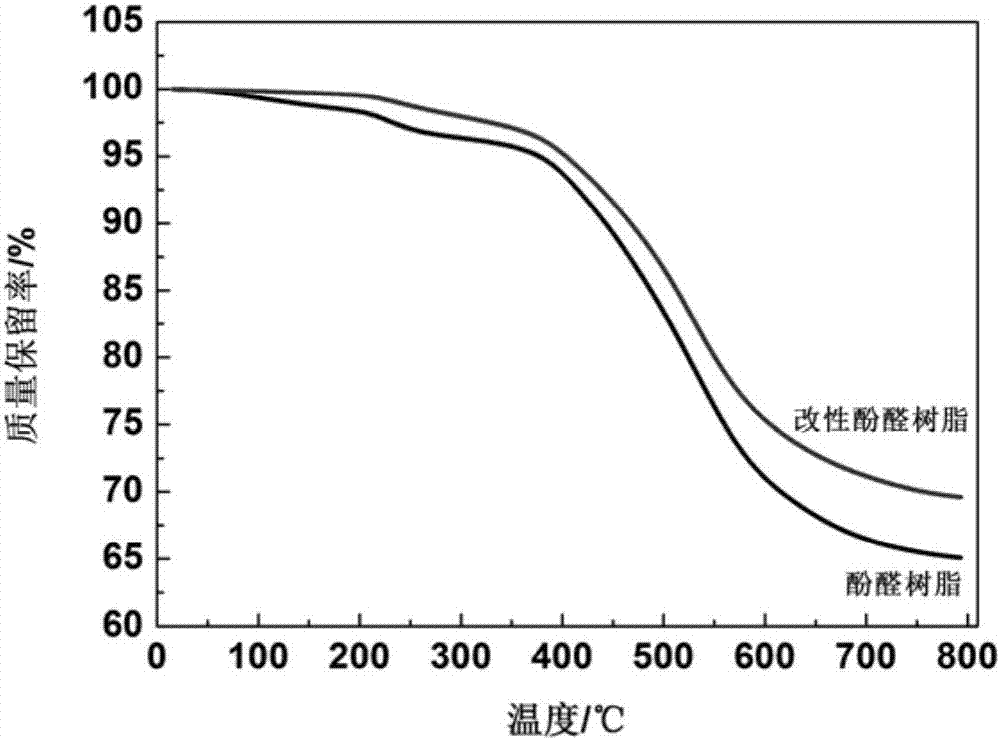

A technology of catechol aryl borate and phenolic resin, which is applied in the field of preparation of catechol aryl borate modified phenolic resin, can solve the problems of unstable product quality and high curing temperature, and achieve excellent storage stability properties, high thermal stability, improved effect of curing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

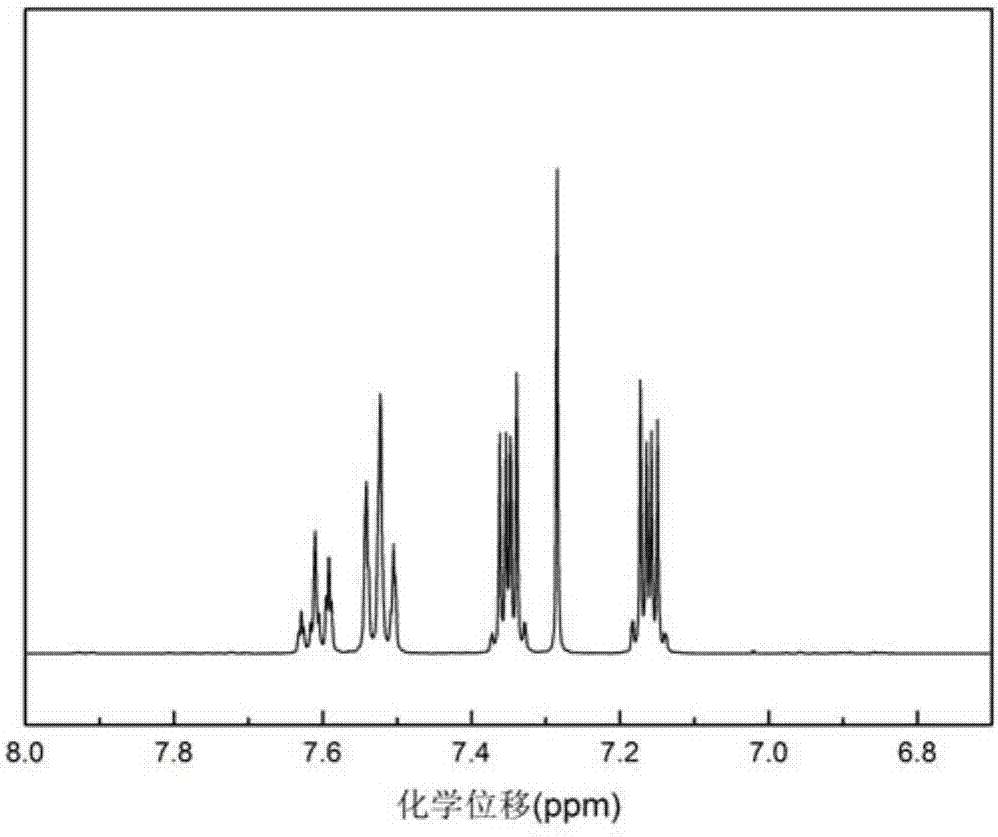

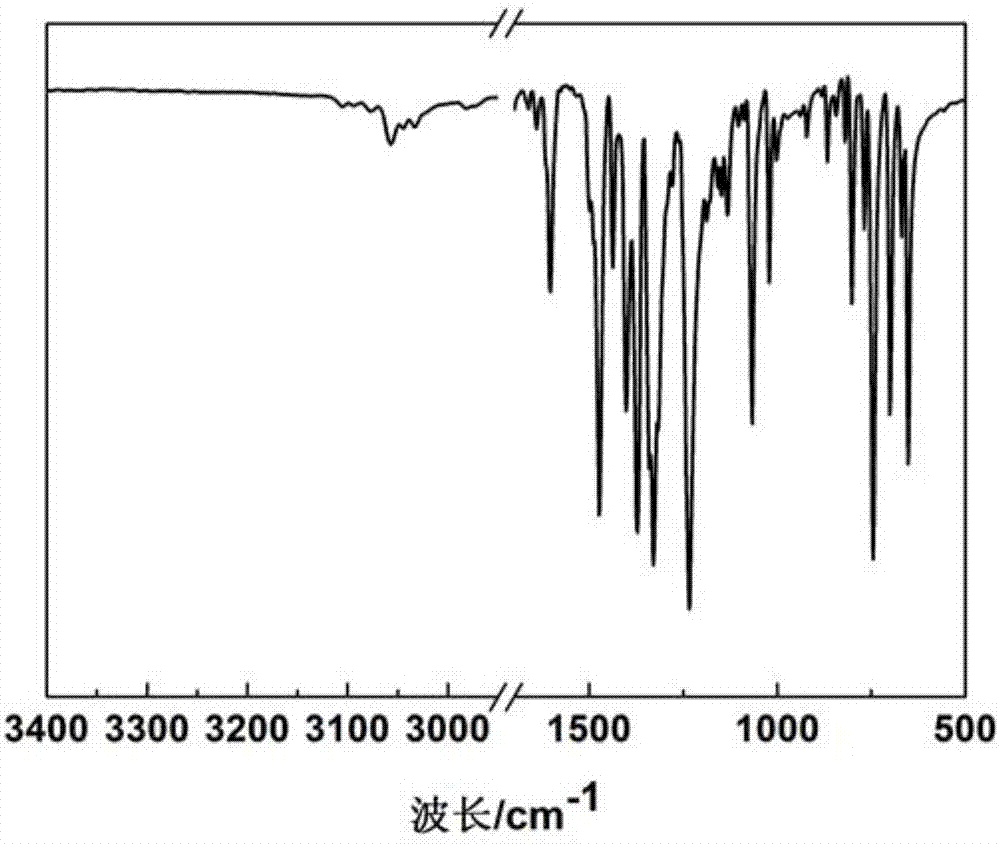

[0031] Step 1: According to the molar ratio of phenylboronic acid:catechol=1:1. First, add 2.00g of phenylboric acid and 1.80g of catechol to a four-necked flask equipped with a stirring blade, thermometer, thermocouple and condenser, add 90mL of toluene as solvent and water-carrying agent, and stir to make the contents of the bottle Mix well, heat up to 110°C, reflux for 4h. During the reflux process, a Dean-Stark device was used to separate the water produced in the reaction.

[0032] Step 2: Cool the reaction slowly to room temperature. Under vacuum conditions, vacuum distillation was performed to remove the remaining solvent to obtain a white solid. After recrystallization, a pure aryl boronic acid catechol ester compound is obtained.

[0033] Step 3: Add the aryl boronic acid catechol ester compound prepared in step 2 to the thermosetting phenolic resin, grind uniformly, and then transfer to a petri dish covered with a polytetrafluoroethylene film, and place in a vacuum ove...

Embodiment 2

[0039] Step 1: According to the molar ratio of boric acid: catechol=1:1. First, add 2.00g boric acid and 1.12g catechol to a four-necked flask equipped with a stirring blade, thermometer, thermocouple and condenser, add 90mL of toluene as solvent and water-carrying agent, and stir to make the contents of the bottle evenly mixed , The temperature was raised to 110°C, and the reaction was refluxed for 12h. During the reflux process, a Dean-Stark device was used to separate the water produced in the reaction.

[0040] Step 2: Cool the reaction slowly to room temperature. Under vacuum conditions, vacuum distillation was performed to remove the remaining solvent to obtain a gray solid. After recrystallization, a pure boric acid catechol ester compound is obtained.

[0041] Step 3: Add the boric acid catechol ester compound prepared in step 2 to the thermosetting phenolic resin, grind uniformly, and then transfer to a petri dish covered with a polytetrafluoroethylene film, and place i...

Embodiment 3

[0043] Step 1: According to the molar ratio of 4-hydroxymethylphenylboronic acid:catechol=1:1. First, add 2.00 g of 4-hydroxymethyl phenylboronic acid and 1.45 g of catechol to a four-necked flask equipped with a stirring blade, thermometer, thermocouple and condenser, add 80 mL of toluene as a solvent and water-carrying agent, and stir. Mix the contents of the bottle uniformly, heat up to 110°C, and reflux for 12 hours. During the reflux process, a Dean-Stark device was used to separate the water produced in the reaction.

[0044] Step 2: After the reaction is complete, slowly cool to room temperature. Under vacuum conditions, vacuum distillation was performed to remove the remaining solvent to obtain a gray solid. After recrystallization, a pure aryl boronic acid catechol ester compound is obtained.

[0045] Step 3: Add the aryl boronic acid catechol ester compound prepared in step 2 to the thermosetting phenolic resin, grind uniformly, and then transfer to a petri dish covere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com