Preparing method for starch-modified heavy metal trapping agent

A technology of heavy metal trapping agent and starch, which is applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of low amino content and low copper removal rate, so as to increase amino content, Effect of improving copper removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

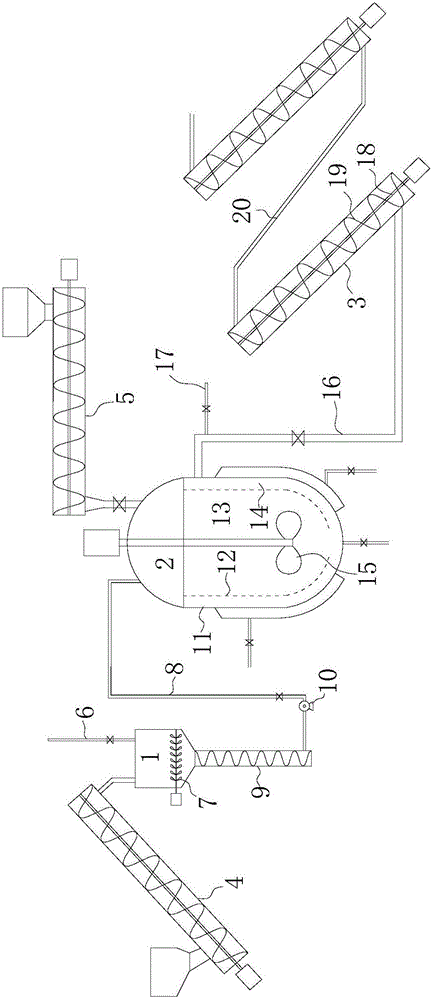

Method used

Image

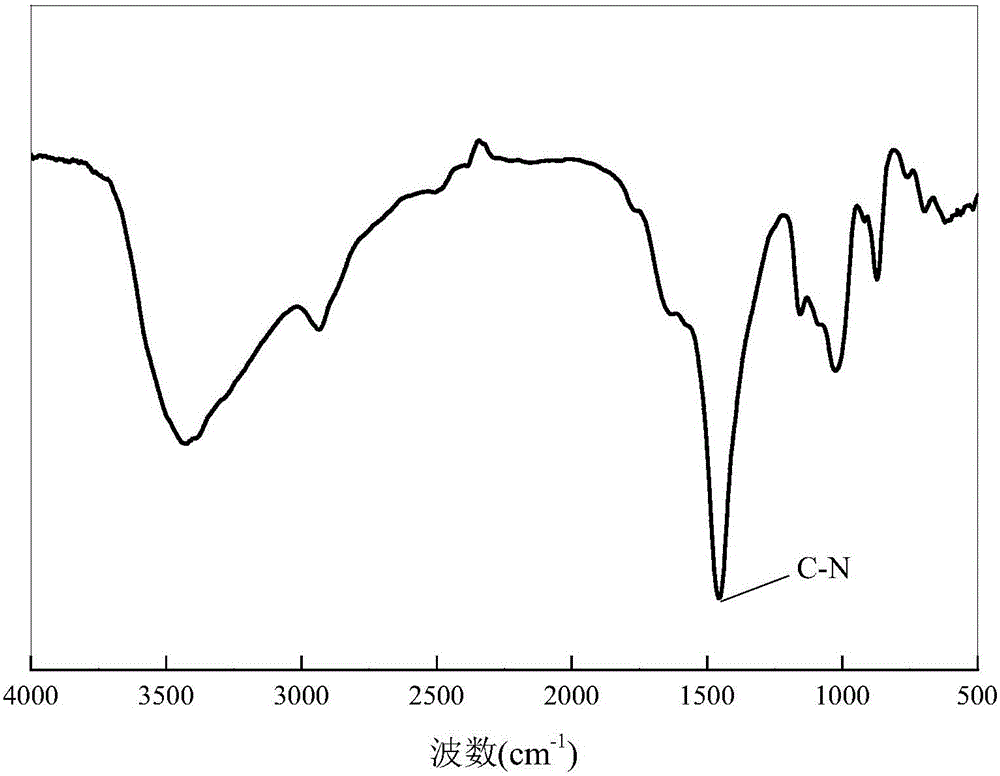

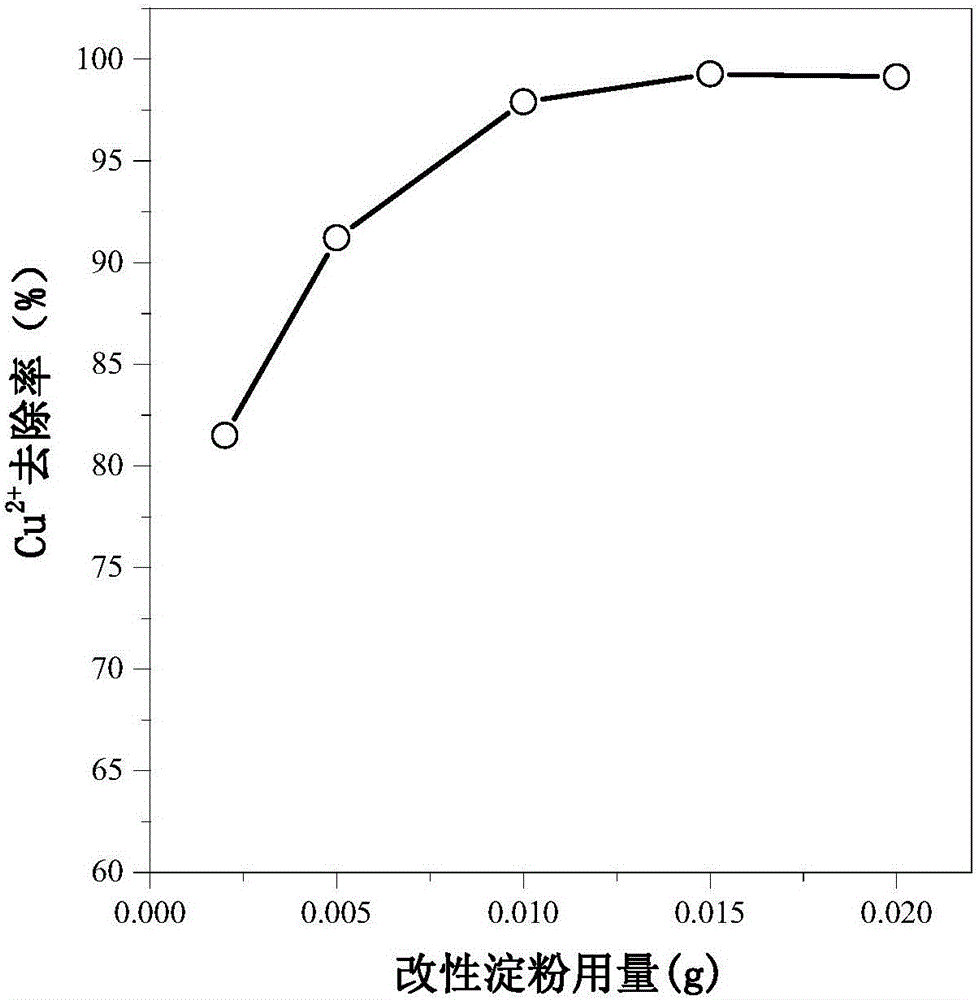

Examples

Embodiment 1

[0080] (1) dissolving cornstarch in a mass fraction of 1% sodium chloride aqueous solution, the mass ratio of cornstarch to sodium chloride aqueous solution is 1:1.5, adding catalyst sodium hydroxide, the mass ratio of catalyst and cornstarch is 1:75 , heated to 25°C, slowly drop epichlorohydrin, the mass ratio of epichlorohydrin and corn starch is 1:40, keep the constant temperature water bath, continue to react for 18 hours, then stop the reaction. Neutralize to about pH=6 with 2% hydrochloric acid, perform vacuum filtration, wash with water, and vacuum-dry for 3 hours. The sedimentation volume of the obtained cross-linked starch is 31 mL, and the water content is 11%.

[0081] (2) Add cross-linked starch, with epichlorohydrin as etherification agent, the mass ratio of etherification agent to cross-linked starch (in percent, the same below) is 85:100, and the mass fraction is 60% of high chlorine Acid (aqueous solution) was used as the initiator, and the mass ratio of the in...

Embodiment 2

[0092](1) dissolving cornstarch in a mass fraction of 1% sodium chloride aqueous solution, the mass ratio of cornstarch to sodium chloride aqueous solution is 1:1.5, adding catalyst sodium hydroxide, the mass ratio of catalyst and cornstarch is 1:75 , heated to 25°C, slowly dropwise adding epichlorohydrin, the mass ratio of epichlorohydrin to corn starch is 1:40, in a constant temperature water bath, continue to react for 14 hours, then stop the reaction. Neutralize with 2% hydrochloric acid to about pH=6, carry out vacuum filtration, wash with water, and vacuum dry for 3 hours. The sedimentation volume of the obtained cross-linked starch is 33mL, and the water content is 11%.

[0093] (2) add cross-linked starch, take epichlorohydrin as etherification agent, the mass ratio of etherification agent and cross-linked starch is 85:100, and be 60% perchloric acid (aqueous solution) as initiator with mass fraction, The mass ratio of initiator and cross-linked starch was 0.74:100, an...

Embodiment 3

[0097] (1) dissolving cornstarch in a mass fraction of 1% sodium chloride aqueous solution, the mass ratio of cornstarch to sodium chloride aqueous solution is 1:1.5, adding catalyst sodium hydroxide, the mass ratio of catalyst and cornstarch is 1:75 , heated to 25°C, slowly dropwise adding epichlorohydrin, the mass ratio of epichlorohydrin to corn starch is 1:40, in a constant temperature water bath, continue to react for 8 hours, then stop the reaction. Neutralize to about pH=6 with 2% hydrochloric acid, perform vacuum filtration, wash with water, and vacuum-dry for 3 hours. The sedimentation volume of the obtained cross-linked starch is 41 mL, and the water content is 11%.

[0098] (2) add cross-linked starch, take epichlorohydrin as etherification agent, the mass ratio of etherification agent and cross-linked starch is 85:100, and be 60% perchloric acid (aqueous solution) as initiator with mass fraction, The mass ratio of initiator and cross-linked starch was 0.65:100, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com