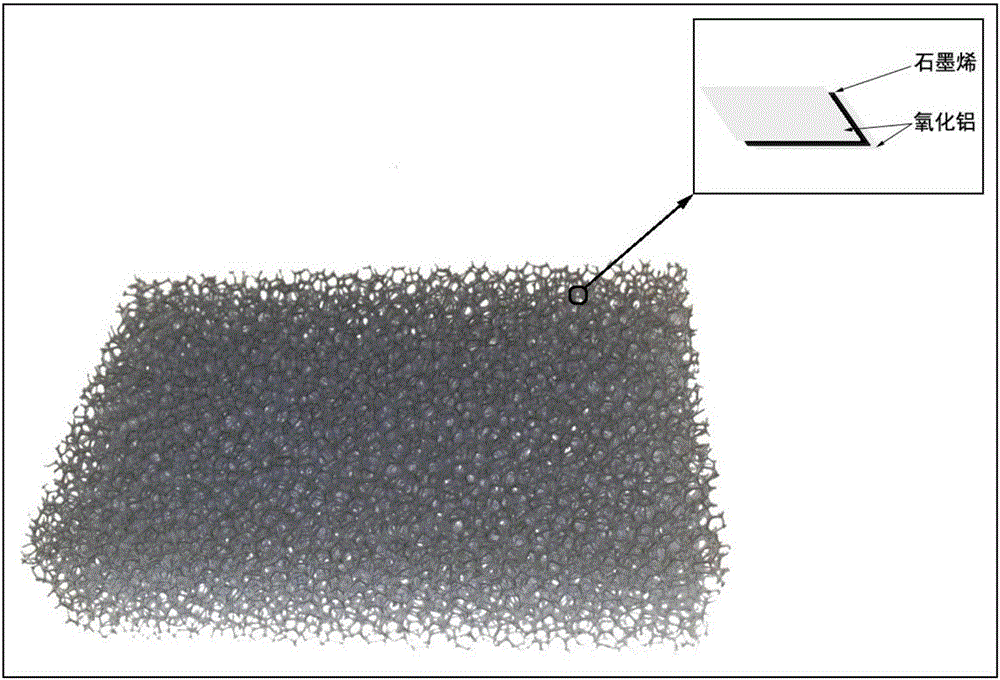

Preparation method of high-temperature and oxidation resisting heat conduction alumina/graphene foam composite material

A technology of graphene foam and composite materials, which is applied in the preparation of alumina/hydroxide, etc., can solve problems such as defects in anti-oxidation performance, and achieve the effect of simple and controllable coating and high oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The graphene oxide powder was added to deionized water for stirring and dispersing, and was stirred at room temperature for 3 hours at a rotational speed of 400 r / min to prepare a graphene oxide aqueous solution with a concentration of 2 mg / ml. 40ml of graphene oxide aqueous solution was placed in the hydrothermal reactor, then the hydrothermal reactor was moved to a muffle furnace and heated to 170 ° C and kept for 10 hours, and the graphene hydrogel obtained by the reaction was frozen after cooling to room temperature to -40°C and freeze-dried at a pressure of 20Pa, then the pure graphene aerogel obtained by freeze-drying and 0.7g of anhydrous aluminum chloride powder were added to ethanol to carry out ultrasonic dispersion, and the power of 300W was ultrasonicated at room temperature for 2 Hour. The mixed suspension of pure graphene aerogel and aluminum chloride solution was added to the hydrothermal reactor, and then the hydrothermal reactor was placed in a muffle f...

Embodiment 2

[0033]The graphene oxide powder was added to deionized water for stirring and dispersion, and stirred at a speed of 500 r / min at room temperature for 2 hours to prepare a graphene oxide aqueous solution with a concentration of 3 mg / ml. 50ml of graphene oxide aqueous solution was placed in the hydrothermal reactor, then the hydrothermal reactor was moved to a muffle furnace and heated to 190 ° C and kept for 12 hours, and the graphene hydrogel obtained by the reaction was frozen after cooling to room temperature. to -30°C and freeze-dried at a pressure of 10Pa, then the pure graphene aerogel obtained by freeze-drying and 0.3g of anhydrous aluminum chloride powder were added to ethylene glycol for ultrasonic dispersion, and the power was 200W at room temperature. Sonicate for 1 hour. The mixed suspension of pure graphene aerogel and aluminum chloride solution was added to the hydrothermal reactor, and then the hydrothermal reactor was placed in a muffle furnace and heated to 180...

Embodiment 3

[0035] The graphene oxide powder was added to deionized water for stirring and dispersion, and stirred at a speed of 300 r / min at room temperature for 2.5 hours to prepare a graphene oxide aqueous solution with a concentration of 2.5 mg / ml. 45ml of graphene oxide aqueous solution was placed in the hydrothermal reactor, then the hydrothermal reactor was moved to a muffle furnace and heated to 200 ° C and kept for 14 hours, and the graphene hydrogel obtained by the reaction was frozen after cooling to room temperature to -50°C and freeze-dried at a pressure of 15Pa, then the pure graphene aerogel obtained by freeze-drying and 0.5g of anhydrous aluminum chloride powder were added to methanol for ultrasonic dispersion, and the power of 250W was ultrasonicated at room temperature for 1.5 Hour. The mixed suspension of pure graphene aerogel and aluminum chloride solution was added to the hydrothermal reactor, and then the hydrothermal reactor was placed in a muffle furnace and heated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com