Energy-saving environment-friendly extrusion device for intelligently controlling recycled plastic based on PLC

A recycled plastic, energy-saving and environmentally-friendly technology, applied in the field of plastic processing machinery, to achieve the effects of enhancing the use efficiency, increasing the service life, and increasing the efficiency of silk production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

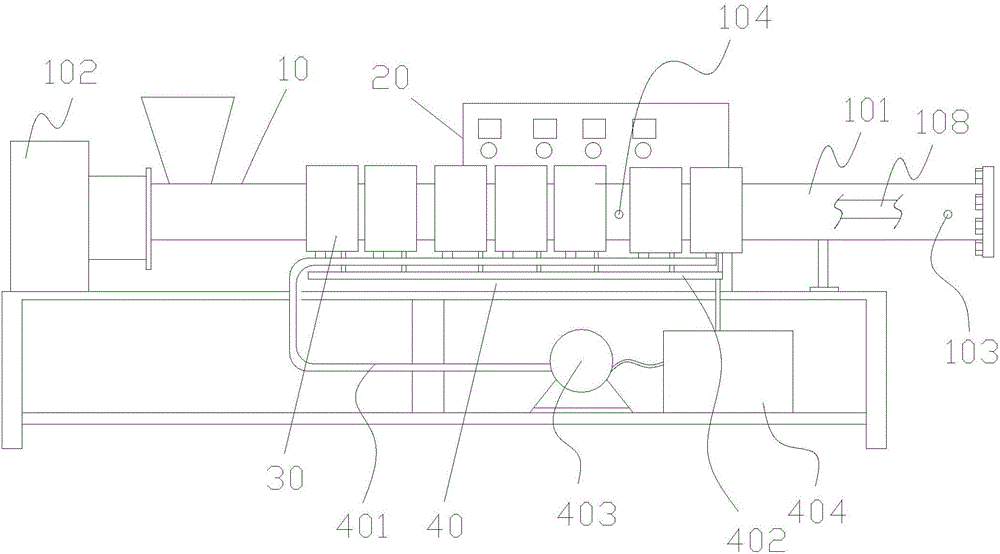

[0026] like figure 1 , figure 2 As shown, an energy-saving and environmentally friendly extrusion device based on PLC intelligent control of recycled plastic includes an extrusion part 10 and a programmable controller 20. The extrusion part 10 mainly includes an extrusion barrel 101 and is connected with the extrusion barrel 101. The transmission mechanism 102 includes a motor and a reducer; a heating screw 108 is arranged in the extrusion barrel 101, and a heating wire 105 is arranged in the heating screw 108, and the heating wire 105 generates heat so that the heating screw 108 absorbs heat energy, Therefore, the material in the extrusion barrel 101 is heated, and the physical and chemical properties of the recycled plastic are further improved, and its strength is improved; the heating wire 105 arranged in the heating screw 108 is static and does not rotate with the heating screw 108; mainly A high temperature resistant bearing 106 is installed in the heating screw 108 , ...

Embodiment 2

[0037] like image 3 As shown, an energy-saving and environmentally friendly extrusion device based on PLC intelligent control of recycled plastic includes an extrusion part 10 and a programmable controller 20. The extrusion part 10 mainly includes an extrusion barrel 101 and an extrusion barrel 101. The transmission mechanism 102 connected by transmission, the transmission mechanism 102 includes a motor and a reducer; a heating screw is arranged in the extrusion barrel 101, and a heating wire is arranged in the heating screw, and the heating wire is heated so that the heating screw absorbs heat energy, thereby It heats the material in the extrusion barrel 101, further improves the physical and chemical properties of the recycled plastic, and improves its strength; an ultrasonic probe 103 is installed at the front end of the extrusion barrel 101, and a temperature sensor is installed in the middle of the extrusion barrel 101. The sensing probe 104, the ultrasonic probe 103 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com