Special high-performance heat conducting insulation alloy screw rod for reworked plastic modification

A technology of heat conduction, insulation and recycled plastics, applied in the field of plastic processing equipment, can solve problems such as unstable performance, insufficient ball milling fineness, screw expansion, etc., and achieve the effects of easy automatic control, improved modification quality, and increased silk production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] A special high-performance heat-conducting and insulating alloy screw for the modification of recycled plastics, made of the following components: 100kg of stainless steel powder, 0.5kg of titanium carbide, 0.4kg of calcined kaolin, 1.2kg of silicotungstic acid, 5kg of nano-ceramic powder, and tungsten carbide 0.6kg, silicon carbide 3kg, tungstate 0.8kg, zirconia 0.5kg, magnesium aluminum alloy 4kg, calcined calcium chrome garnet 0.4kg, graphene microflake 0.01kg; the working temperature of the screw can reach 500 ℃, and the performance is stable. Uniform heat conduction, wear resistance, corrosion resistance and other advantages, high extrusion efficiency. Made of high-performance heat-conducting and insulating alloy material, the heat-conducting effect is good, and the material is heated evenly.

Embodiment 2

[0014] A special high-performance heat-conducting and insulating alloy screw for the modification of recycled plastics, made of the following components: 100kg of stainless steel powder, 0.5kg of titanium carbide, 0.4kg of calcined kaolin, 1.2kg of silicotungstic acid, 5kg of nano-ceramic powder, and tungsten carbide 0.6kg, silicon carbide 3kg, tungstate 0.8kg, zirconia 0.5kg, magnesium aluminum alloy 4kg, calcined calcium chrome garnet 0.4kg, graphene microflake 0.01kg; the working temperature of the screw can reach 500 ℃, and the performance is stable. Uniform heat conduction, wear resistance, corrosion resistance and other advantages, high extrusion efficiency. Made of high-performance heat-conducting and insulating alloy material, the heat conduction effect is good, and the material is heated evenly;

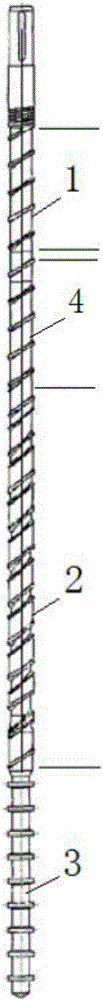

[0015] Such as figure 1 As shown, the above-mentioned screw rod is divided into feeding section 1, melting section 4, modification section 2 and extrusion section 3 in turn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com