Automatic moving and fetching device for neodymium iron boron performed compact

A neodymium-iron-boron, removal technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of material waste, low production efficiency, large proportion of manual work, etc., to prevent raw materials from missing edges and corners, improving The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

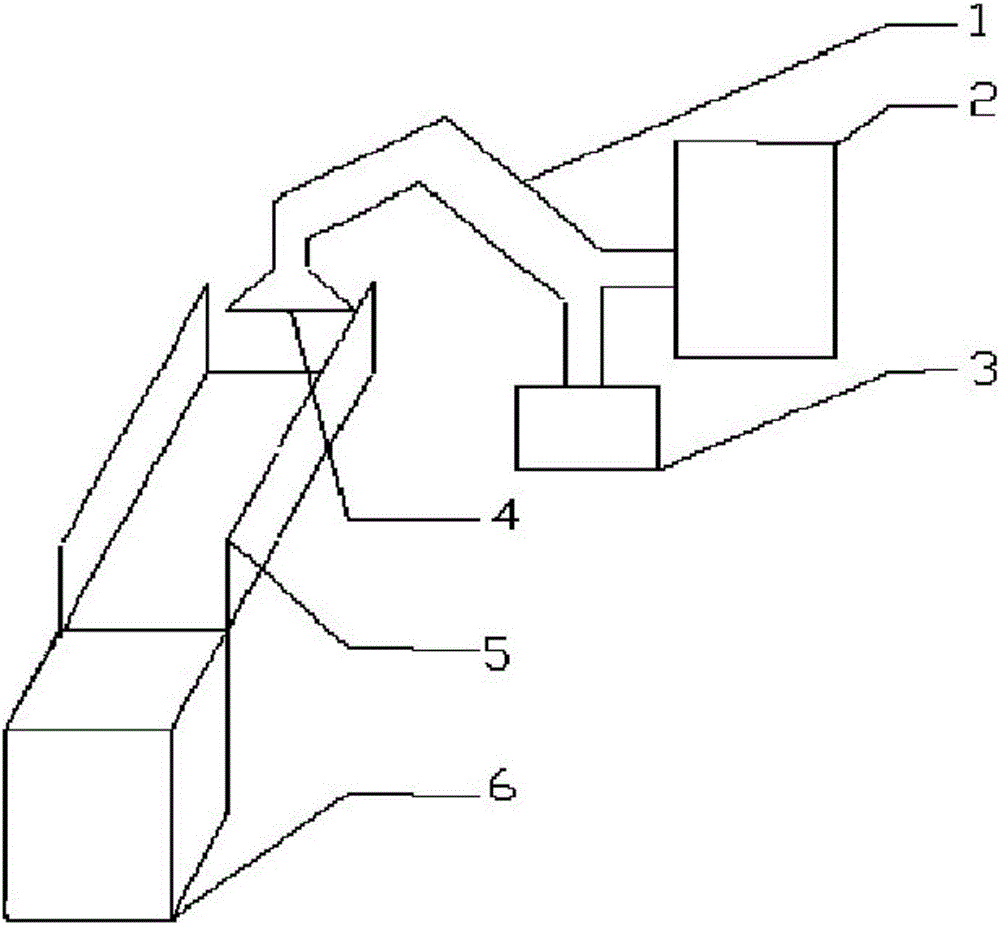

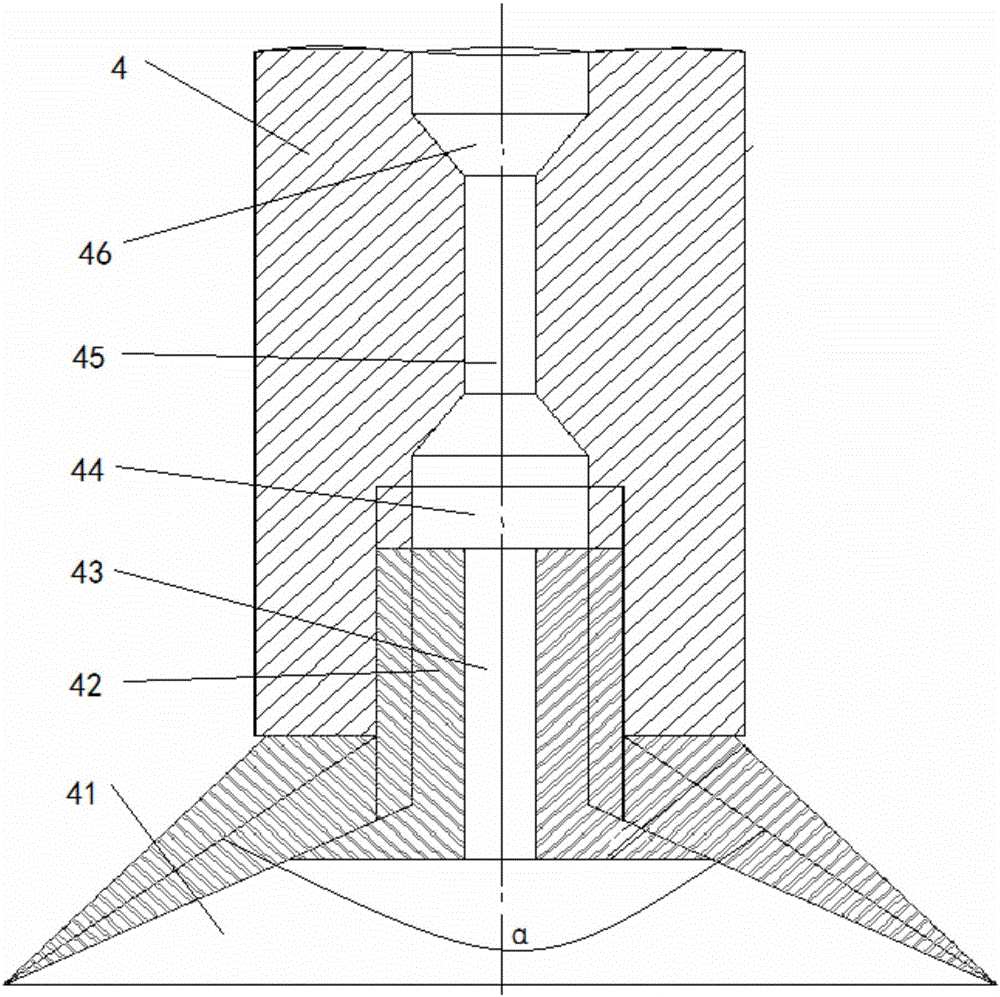

[0023] figure 1 It is a schematic diagram of the overall structure of an automatic removal device for NdFeB prefabricated compacts of the present invention. Such as figure 1 As shown, the device of the present invention includes a vacuum adsorption unit, a prefabricated compact moving protection channel 5, a prefabricated compact receiving platform 6, a PLC control circuit, and a servo unit (not shown), wherein the vacuum adsorption unit is used for removing NdFeB prefabricated compact, which includes a gas supply unit (not shown, a nitrogen supply unit in this embodiment), a gas channel 1 (a nitrogen channel in this embodiment), a vacuum generating unit 2, a powder collector 3 and sucker4. The gas supply unit communicates with the gas flow channel 1 and is used for supplying inert gas (such as nitrogen) to the gas channel to protect the NdFeB prefabricated compact. The vacuum generating unit 2 communicates with the gas channel 1 and is used to form negative pressure in the...

Embodiment 2

[0029] Except that the thickness of the sponge in embodiment 1 is replaced by 15mm by 10mm, all the other components and parameters are the same as embodiment 1.

Embodiment 3

[0031] Except that the taper angle α in embodiment 1 is replaced by 105° from 135°, other components and parameters are the same as in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com