Closed back pressure bidirectional upsetting extrusion forming method for preparing refractory metal ultrafine grain material

A refractory metal, ultra-fine grain technology, used in metal processing equipment, manufacturing tools, forging/pressing/hammer devices, etc. Small blank size and other problems, to achieve the effect of improving rigidity, large deformation, and solving the problem of eccentric load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

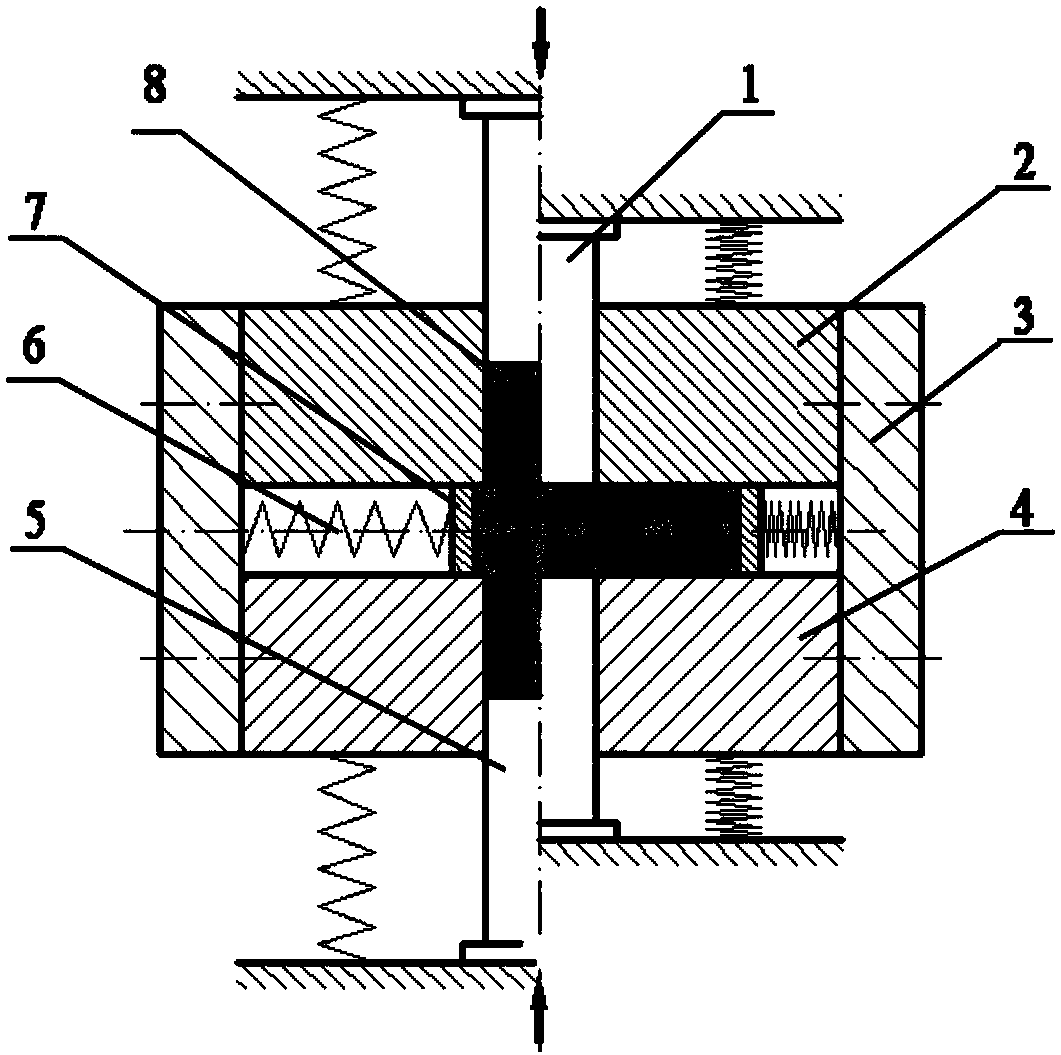

[0026] see figure 1 , this embodiment discloses a closed-type back-pressure two-way upsetting extrusion forming method for preparing refractory metal ultrafine-grained materials. The forming method is based on a combined die, which consists of an upper die 2 and a lower die Die 4 is formed, the combined die forms a cross-shaped channel, the cross-shaped channel is formed by the vertical intersection of the first channel and the second channel, the cross-shaped channel is symmetrical to the center line of the first channel, and the cross-shaped channel is relatively The center line of the second channel is symmetri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com