Composition for forming dye polarizer and dye polarizer

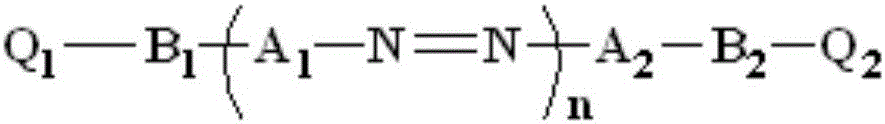

A technology of polarizer and composition, which is applied in the field of compositions for forming dye-type polarizers and dye-type polarizers, and achieves the effects of good heat resistance, high orientation, and prevention of randomization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

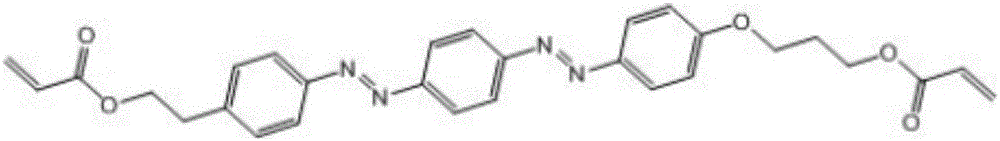

[0173] : Synthesis of Curable Anisotropic Dye (Chemical Formula 1a)

[0174] Formaldehyde (1.2eq) and sodium bisulfate (1eg) were added to water and stirred for 1 hour. Aniline (1 eq) was added to the solution and stirred at 60°C for 16 hours. After the reaction, the solution was cooled to a temperature below 0°C, thereby precipitating unpurified product dissolved in the solvent, then filtered, washed with ethyl acetate, and dried in a vacuum oven. Thus, Intermediate 1 was prepared.

[0175] A DMF solution of 4-hydroxyethylaniline (1 eq) was mixed with sodium nitrite (1.1 eq) dissolved in distilled water, and 1N HCl was slowly added thereto at 0°C, followed by stirring for about 1 hour. The stirred solution was added dropwise to a solution of Intermediate 1 (1 eq) and sodium acetate (3.5 eq) dissolved in 40 ml distilled water. At this time, the temperature was maintained at 0°C, and after the dropwise addition, stirring was performed for about 4 hours. After stirring, the ...

preparation Embodiment 2

[0180] : Synthesis of Curable Anisotropic Dye (Chemical Formula 1b)

[0181] Formaldehyde (1.2eq) and sodium bisulfate (1eg) were added to water and stirred for 1 hour. Aniline (1 eq) was added to the solution and stirred at 60°C for 16 hours. After the reaction, the solution was cooled to a temperature below 0°C, thereby precipitating unpurified product dissolved in the solvent, then filtered, washed with ethyl acetate, and dried in a vacuum oven. Thus, Intermediate 1 was prepared.

[0182] A DMF solution of 4-hydroxyethyl-3-fluoro-aniline (1 eq) was mixed with sodium nitrite (1.1 eq) dissolved in distilled water, and 1 N HCl was slowly added thereto at 0 °C, followed by stirring for about 1 Hour. The stirred solution was added dropwise to a solution of Intermediate 1 (1 eq) and sodium acetate (3.5 eq) dissolved in 40 ml distilled water. At this time, the temperature was maintained at 0°C, and after the dropwise addition, stirring was performed for about 4 hours. After s...

preparation Embodiment 3

[0187] : Synthesis of Curable Anisotropic Dye (Chemical Formula 1c)

[0188] Formaldehyde (1.2eq) and sodium bisulfate (1eg) were added to water and stirred for 1 hour. Aniline (1 eq) was added to the solution and stirred at 60°C for 16 hours. After the reaction, the solution was cooled to a temperature below 0°C, thereby precipitating unpurified product dissolved in the solvent, then filtered, washed with ethyl acetate, and dried in a vacuum oven. Thus, Intermediate 1 was prepared.

[0189] A DMF solution of 4-hydroxyethylaniline (1 eq) was mixed with sodium nitrite (1.1 eq) dissolved in distilled water, and 1N HCl was slowly added thereto at 0°C, followed by stirring for about 1 hour. The stirred solution was added dropwise to a solution of Intermediate 1 (1 eq) and sodium acetate (3.5 eq) dissolved in 40 ml distilled water. At this time, the temperature was maintained at 0°C, and after the dropwise addition, stirring was performed for about 4 hours. After stirring, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polarization | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com