Piston skirt profile line structure

A piston skirt and wire structure technology, which is applied to pistons, engine components, machines/engines, etc., can solve problems such as the inability to guarantee piston heat resistance, stable guiding and good sealing functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

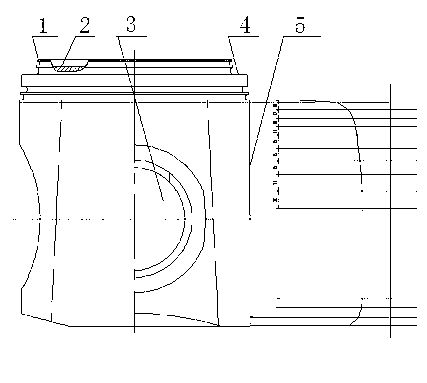

[0008] like figure 1 As shown, the shape line structure of the piston skirt includes a seal ring groove 1, an inner ring support surface 2, a piston pin hole 3, an outer ring support surface 4, and a convex and elliptical shape line 5. The seal ring groove 1 is set on the top skirt cylinder On the mating surface, the inner ring support surface 2 and the outer ring support surface 4 are set on the top of the piston skirt, the piston pin hole 3 is set in the middle of the piston skirt, and the convex and elliptical shape line 5 is set on the outer cylindrical surface of the piston skirt. Invented a piston skirt shape line structure, the outer circle of the piston is designed as a special-shaped outer circle (convex to elliptical), that is, the cross section perpendicular to the piston axis is an ellipse or a modified ellipse, and the ellipticity along the axis direction follows a certain law The convex ellipse of the piston shape is different from the ordinary ellipse. The pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com