Numerical control tension adjusting device for panel production line

A technology for tension adjustment devices and production lines, which is applied in the direction of shearing devices, shearing equipment, manufacturing tools, etc., and can solve problems such as narrowing of spacing, uneven tape, and inability to keep the guiding effect of guide rollers consistent, so as to maintain flatness and reduce split layer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions claimed in the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

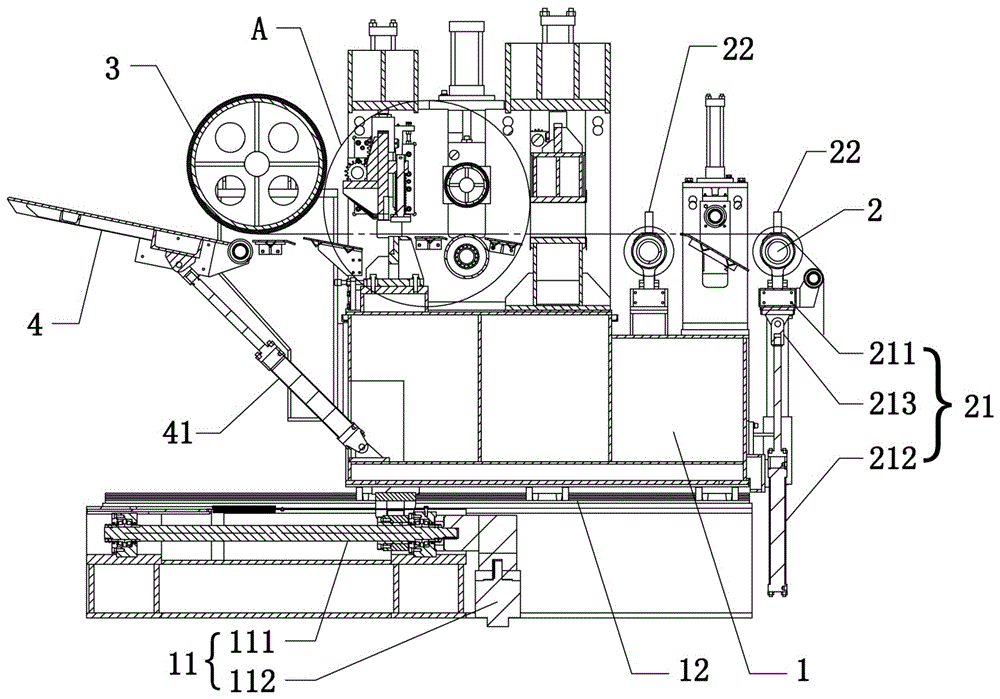

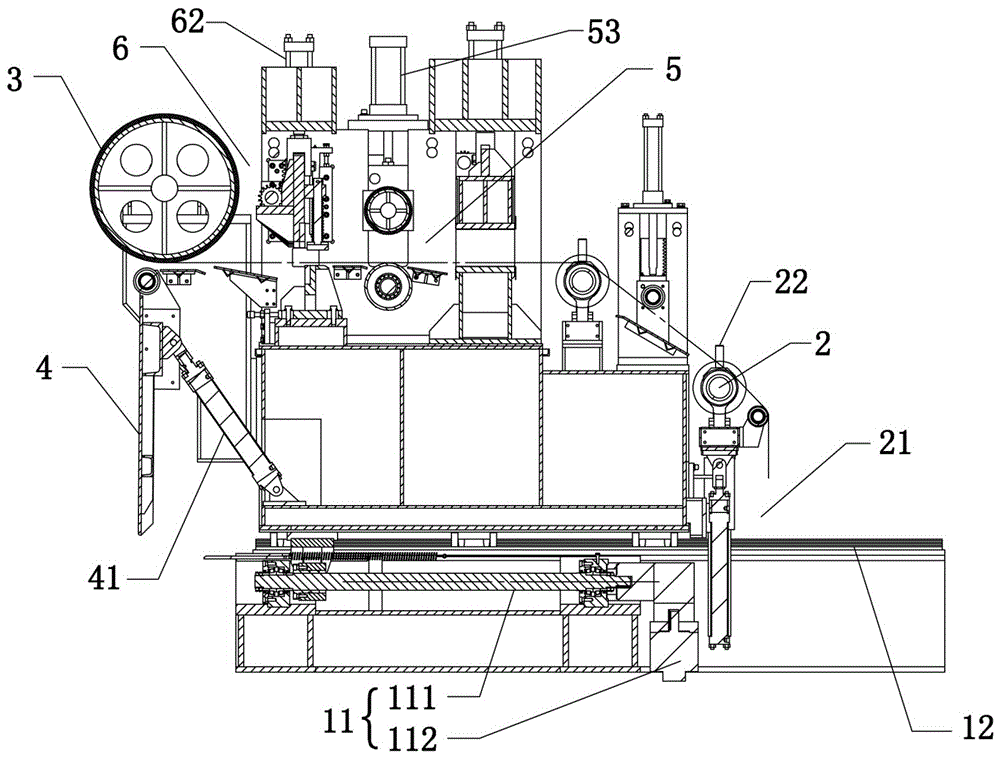

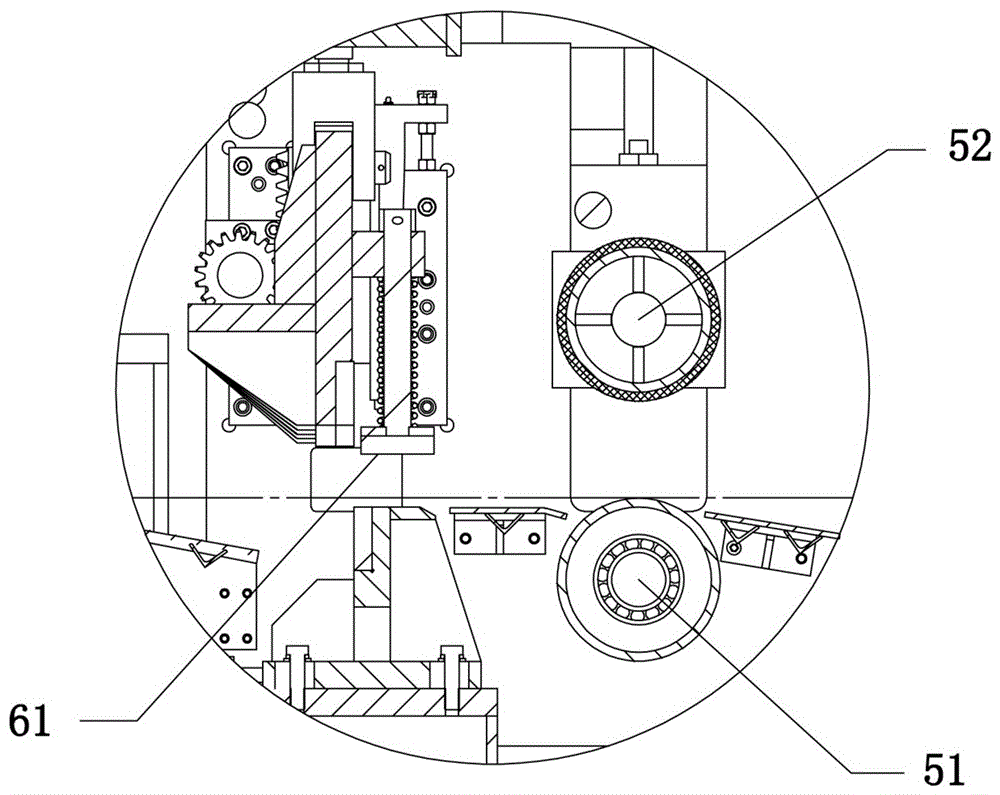

[0017] See attached figure 1 to attach image 3 As shown, a numerically controlled tension adjustment device used in a plate production line in this embodiment includes a moving seat 1 that is slidably connected to a horizontal guide rail 12 extending along the conveying direction of the steel strip, and is used to drive the moving seat 1 horizontally. The sliding mobile base translation mechanism 11, the mobile base translation mechanism 11 includes a horizontal screw 111 threaded with the mobile base 1 and a servo motor 112 for driving the horizontal screw 111 to rotate, and the mobile base 1 is provided with a The separation roller 2 that separates each strip, and the rear side of the separation roller 2 is provided with a guide roller 3 for guiding. Under the precise adjustment, the radius of the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com