Magnetic increase built-in V-shaped adjustable flux motor

A magnetic flux motor and magnetic technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit, electrical components, etc., can solve the problems of uncontrollable demagnetization of alnico permanent magnets, etc., to ensure stability, controllability, change Air-gap flux, risk reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

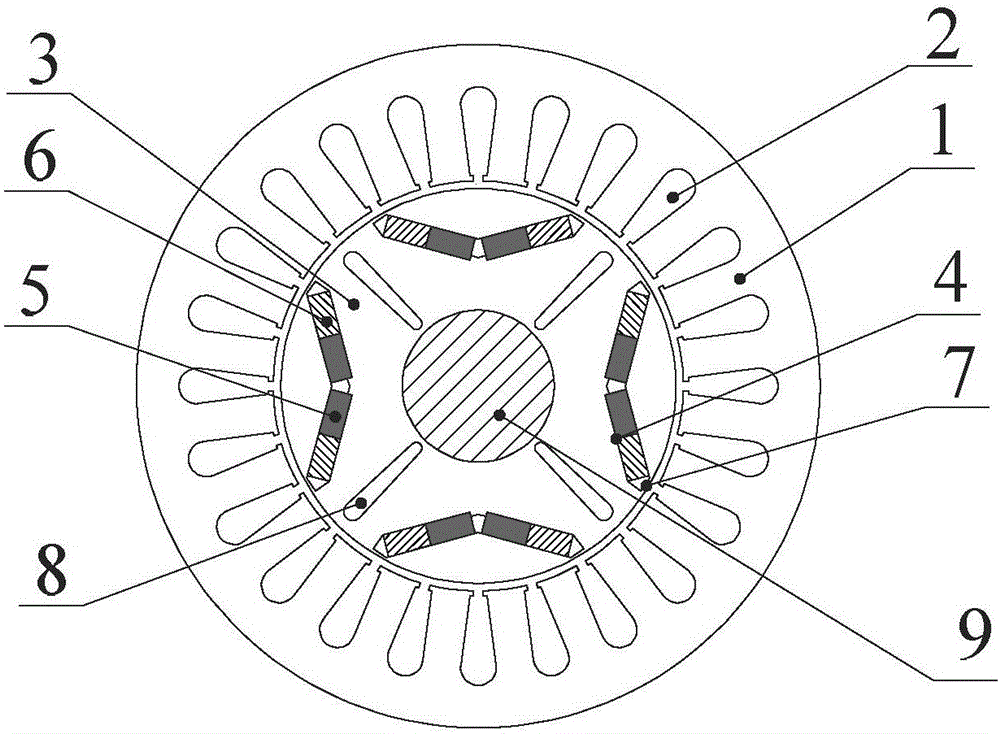

[0018] Specific implementation mode one: the following combination Figure 1 to Figure 3 This embodiment is described. The magnetized built-in V-type adjustable flux motor described in this embodiment includes a stator, a rotor, and a rotating shaft. The stator includes a stator core 1 and an armature winding 2. The armature winding 2 is arranged on the winding of the stator core 1. In the groove, the rotating shaft 9 is made of cast steel, the stator and the rotating shaft 9 are the same as the conventional permanent magnet synchronous motor; the rotor includes a permanent magnet slot, NdFeB magnetic pole 5, AlNiCo magnetic pole 6, magnetic bridge 7 and quadrature axis magnetic barrier 8. The rotor is alternately and uniformly arranged with V-shaped permanent magnet slots 4 and quadrature-axis magnetic barriers 8 along the circumferential direction. Both the V-shaped permanent magnet slots 4 and the quadrature-axis magnetic barriers 8 run through the entire motor in the axial ...

Embodiment 1

[0021] to combine figure 1 To illustrate this embodiment, the magnetization-increased built-in V-type adjustable flux motor includes a stator, a rotor, and a rotating shaft. The stator in the present invention includes a stator core 1 and an armature winding 2. The armature winding 2 is arranged in the slot of the stator iron core, and the rotating shaft 9 is made of cast steel. The stator and shaft 9 are the same as those of conventional permanent magnet synchronous motors; V-shaped permanent magnet slots 4 and quadrature-axis magnetic barriers 8 are alternately and uniformly arranged along the circumferential direction. Both V-shaped permanent magnet slots 4 and quadrature-axis magnetic barriers 8 run through the entire motor in the axial direction. V-shaped permanent magnet slots 4 have two rectangular installations. In each rectangular slot, a set of NdFeB magnetic poles 5 and AlNiCo magnetic poles 6 are set respectively. The magnetization direction of the boron magnetic ...

Embodiment 2

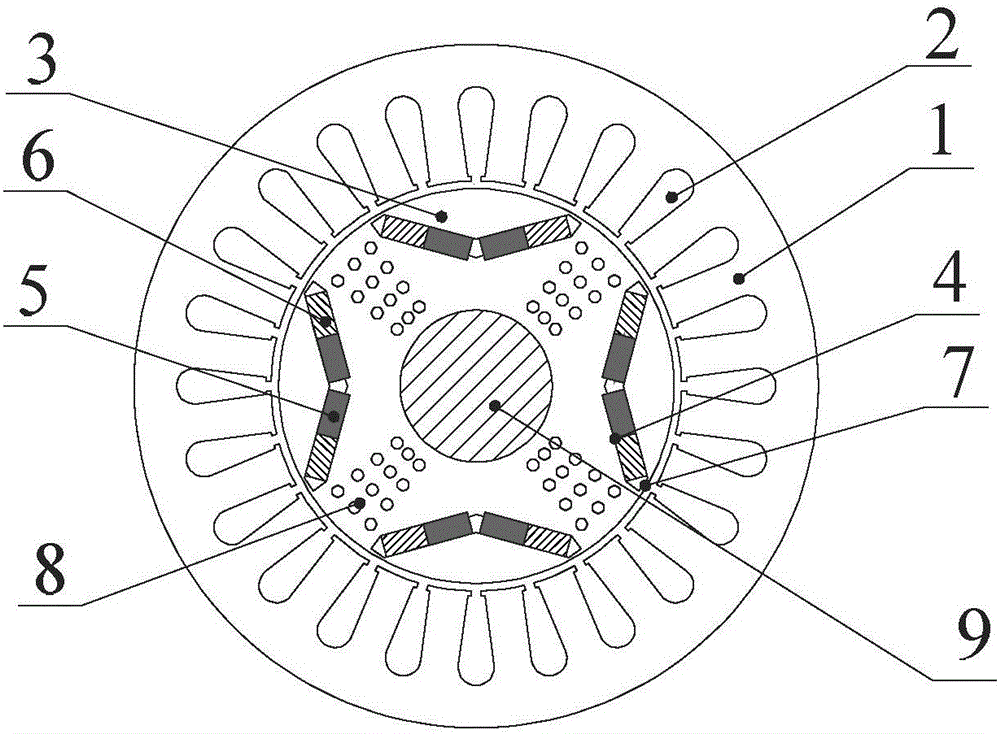

[0023] to combine figure 2 Note that the difference between this embodiment and Embodiment 1 is that the quadrature-axis magnetic barrier 8 is a long strip-shaped groove arranged radially along the motor, with smooth ends at both ends, and its interior can also be made of non-magnetically conductive epoxy resin, carbon fiber, etc. , Non-conductive material filling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com