Red and yellow light emitting diode epitaxial wafer and preparation method thereof

A technology of light-emitting diodes and epitaxial wafers, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of low luminous efficiency, achieve the effect of improving luminous efficiency and increasing the recombination probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

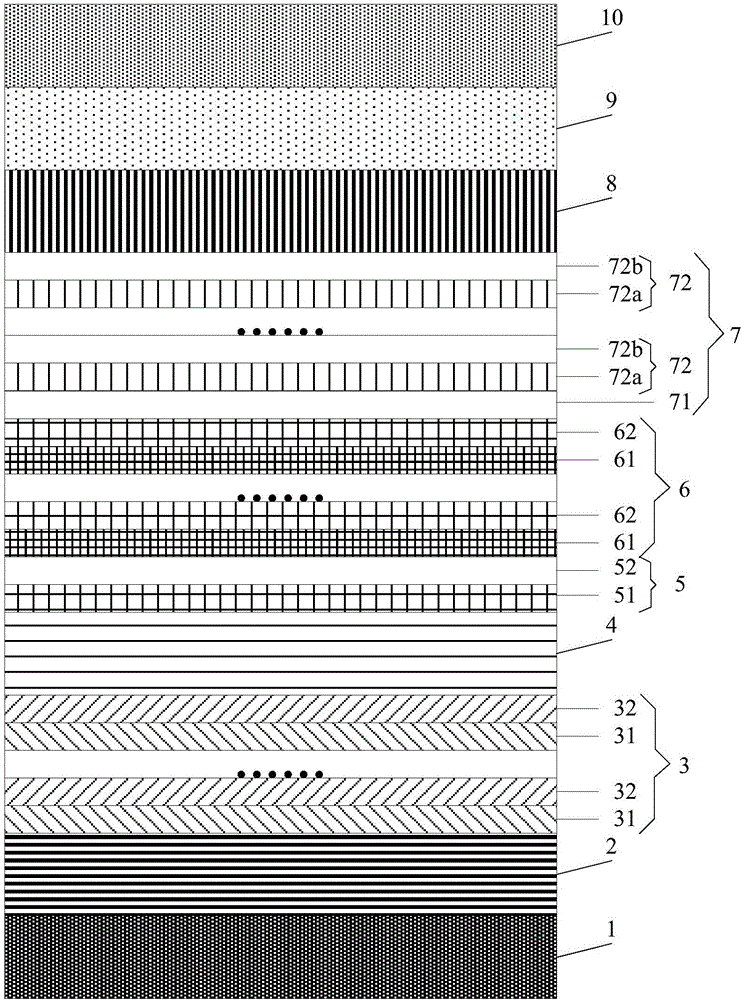

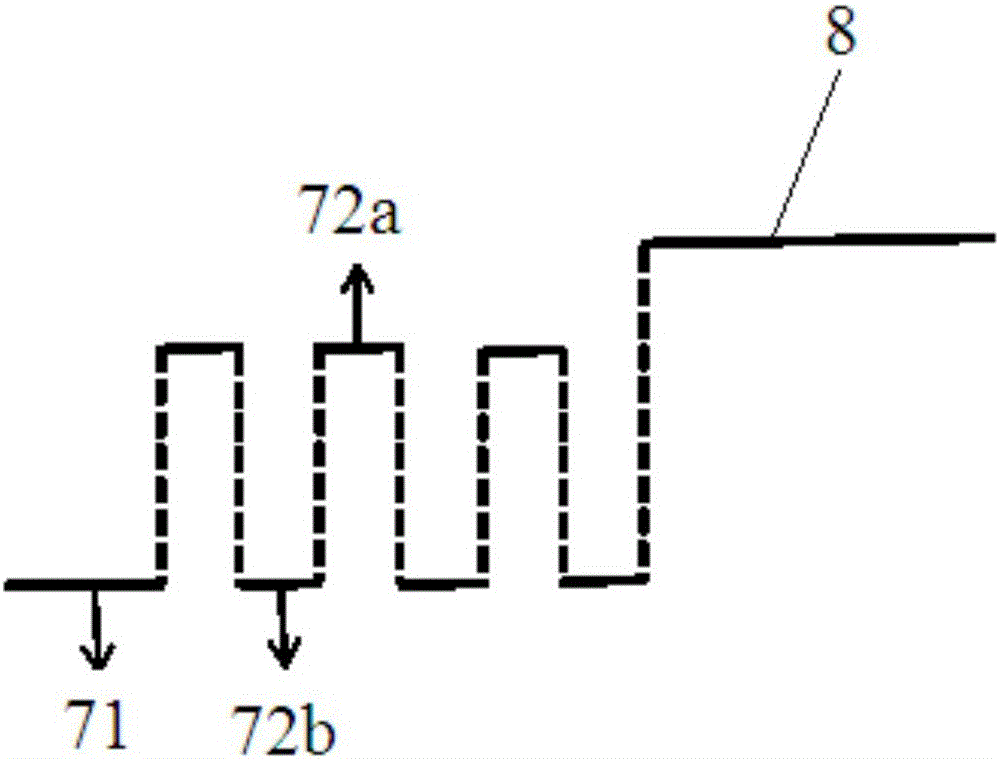

[0035] An embodiment of the present invention provides a red and yellow light emitting diode epitaxial wafer, see figure 1 The red and yellow light emitting diode epitaxial wafer includes an N-type substrate 1, and an N-type buffer layer 2, an N-type reflective layer 3, an N-type confinement layer 4, an electron blocking layer 5, Multi-quantum well layer 6 , hole adjustment layer 7 , P-type confinement layer 8 , P-type current spreading layer 9 , and P-type ohmic contact layer 10 .

[0036] In this embodiment, the N-type substrate 1 is a GaAs substrate; the N-type buffer layer 2 is a GaAs layer; the N-type reflective layer 3 includes alternately stacked AlAs layers 31 and AlGaAs layers 32; the N-type confinement layer 4 is an AlInP layer The electron blocking layer 5 includes AlGaInP layers 51 and AlInP layers 52; the multi-quantum well layer 6 includes alternately stacked quantum well layers 61 and quantum barrier layers 62 (the quantum well layers and the quantum barrier lay...

Embodiment 2

[0080] The embodiment of the present invention provides a method for preparing a red-yellow light-emitting diode epitaxial wafer, which is suitable for preparing the red-yellow light-emitting diode epitaxial wafer provided in Example 1, see image 3 , the preparation method comprises:

[0081] Step 201: forming an N-type buffer layer on an N-type substrate.

[0082] In this embodiment, the N-type substrate is a GaAs substrate; the N-type buffer layer is a GaAs layer.

[0083] Specifically, the N-type substrate can be a 2 or 4-inch 100-plane-offset A+5° GaAs substrate.

[0084] Optionally, the thickness of the N-type substrate may be 340-360 μm.

[0085] Optionally, the doping impurity of the N-type substrate can be silicon element, and the doping concentration of the N-type substrate 1 can be 10 -18 ~2*10 -18 cm -3 .

[0086] Specifically, the growth conditions of the N-type buffer layer may be as follows: the growth temperature is 640-660° C., the flow rate of TMGa (tri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com