Butt joint type concrete pole with wire storage function

A cement electric pole and docking technology, applied in the field of electric equipment manufacturing, can solve the problems of reducing the service life of cement electric poles, affecting the safety performance of cement electric poles, hidden dangers of cement electric poles, etc. , The effect of avoiding core damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

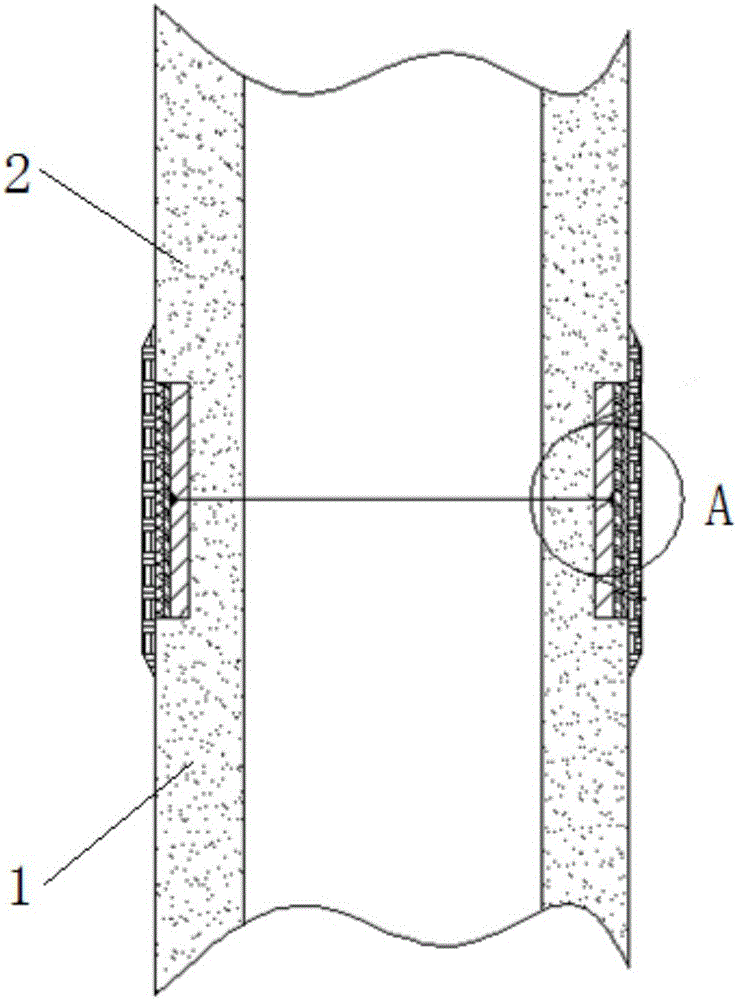

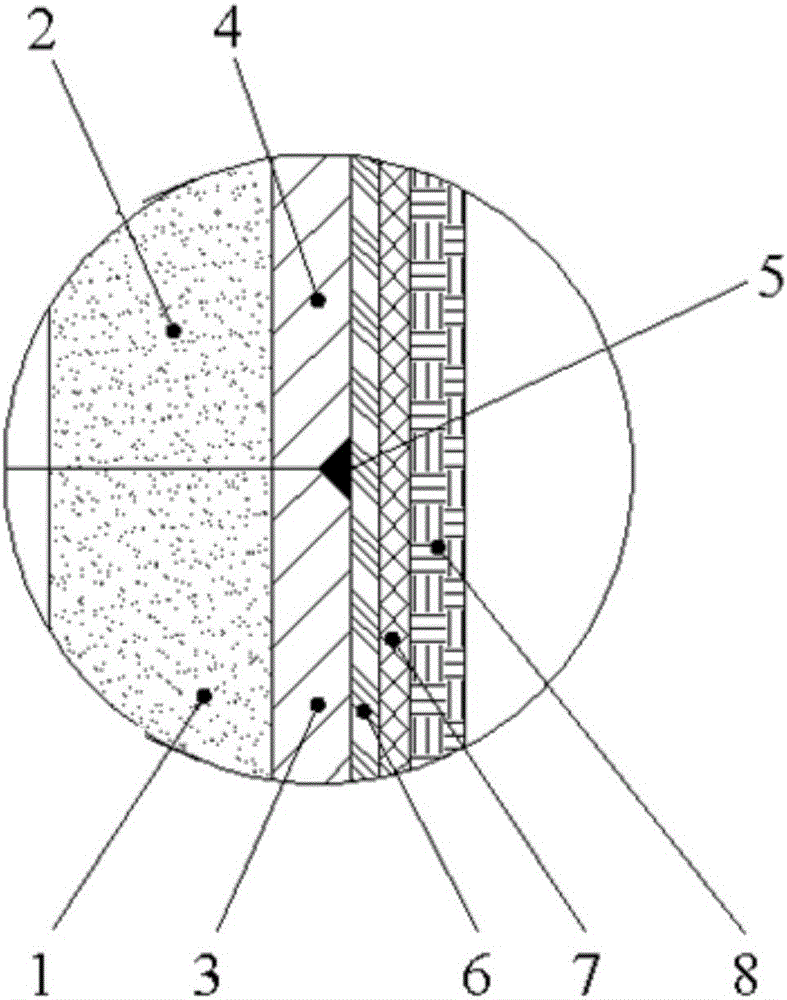

[0033] Such as figure 1 and figure 2 As shown, for super long cement poles that cannot be manufactured as a whole, they are manufactured in sections. In this embodiment, two sections are used, that is, the cement poles are divided into the first pole section 1 and the second pole section 2, and the two pole sections Manufactured separately. The top of the first pole section 1 is provided with a first pole section steel ring 3; the bottom end of the second pole section 2 is provided with a second pole section steel circle 4, and the outer diameters of these two steel circles are exactly the same and less than The outer diameter of the two rod segments.

[0034] The steel plate ring 3 of the first bar section and the steel plate ring 4 of the second bar section are welded to form an integral steel plate fixed ring, and an anti-corrosion treatment layer 6 is coated on the surface of the steel plate fixed ring. An outer protection structure is arranged outside the anticorrosio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com