Tunnel backfill method utilizing vesicle mixing light soil

A technology of light soil and air bubbles, which is applied in the direction of filling, etc., can solve the problems of insufficient compression of the backfill part of the hole slag, great impact on the surrounding environment, and the use of artificial machinery, etc., achieving significant practicability and economy, and low construction noise , The effect of small increase in bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

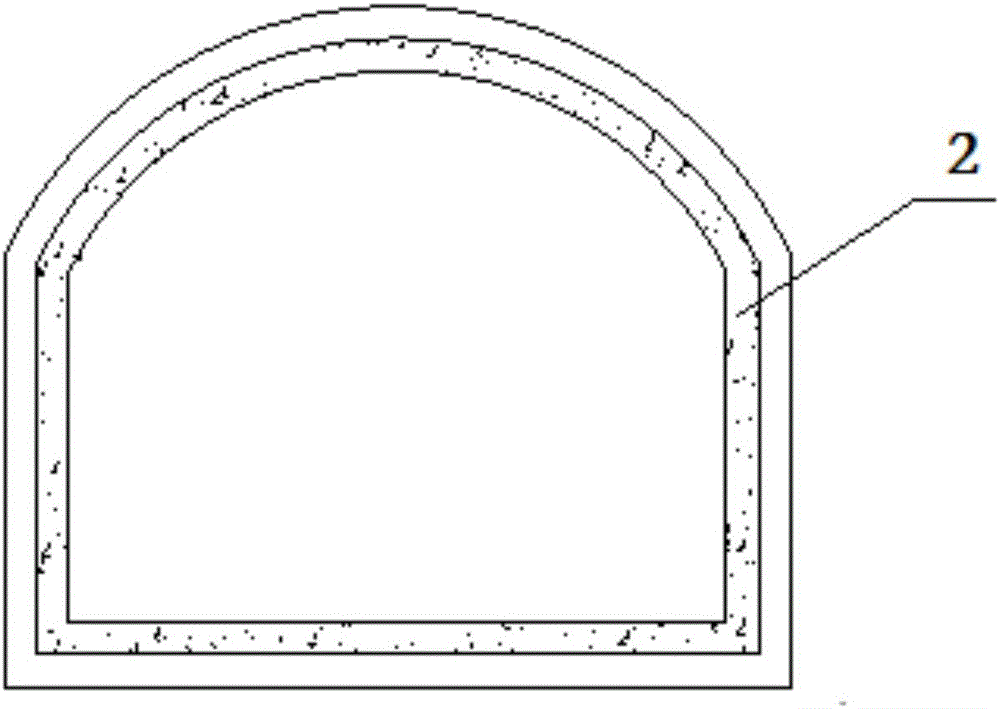

Image

Examples

Embodiment Construction

[0020] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0021] A method for backfilling a tunnel by using air bubbles to mix light soil, comprising the following steps:

[0022] Step S1, blocking the outlet at one end of the pre-backfilled tunnel;

[0023] Step S2, set up a cement tank at the exit of the other end of the tunnel, arrange air bubble mixed light soil integrated equipment and build a water pool, the cement tank transports cement to the air bubble mixed light soil integrated equipment, and the water pool transports water to the air bubble mixed light soil Mass soil integration equipment;

[0024] Step S3, adding foaming agent and additives to the air-bubble mixed light soil integrated equipment, setting the required finished product parameters on the equipme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com