A Construction Method for Consolidating Steel Box Girder and Concrete Pier of Swivel Rigid Frame Bridge

A construction method and concrete technology, which is applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as not being able to meet the force requirements of small-radius swivel bridges, reduce the safety of small-radius swivel bridges, and achieve convenient construction , avoid concentrated force, enhance the effect of cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

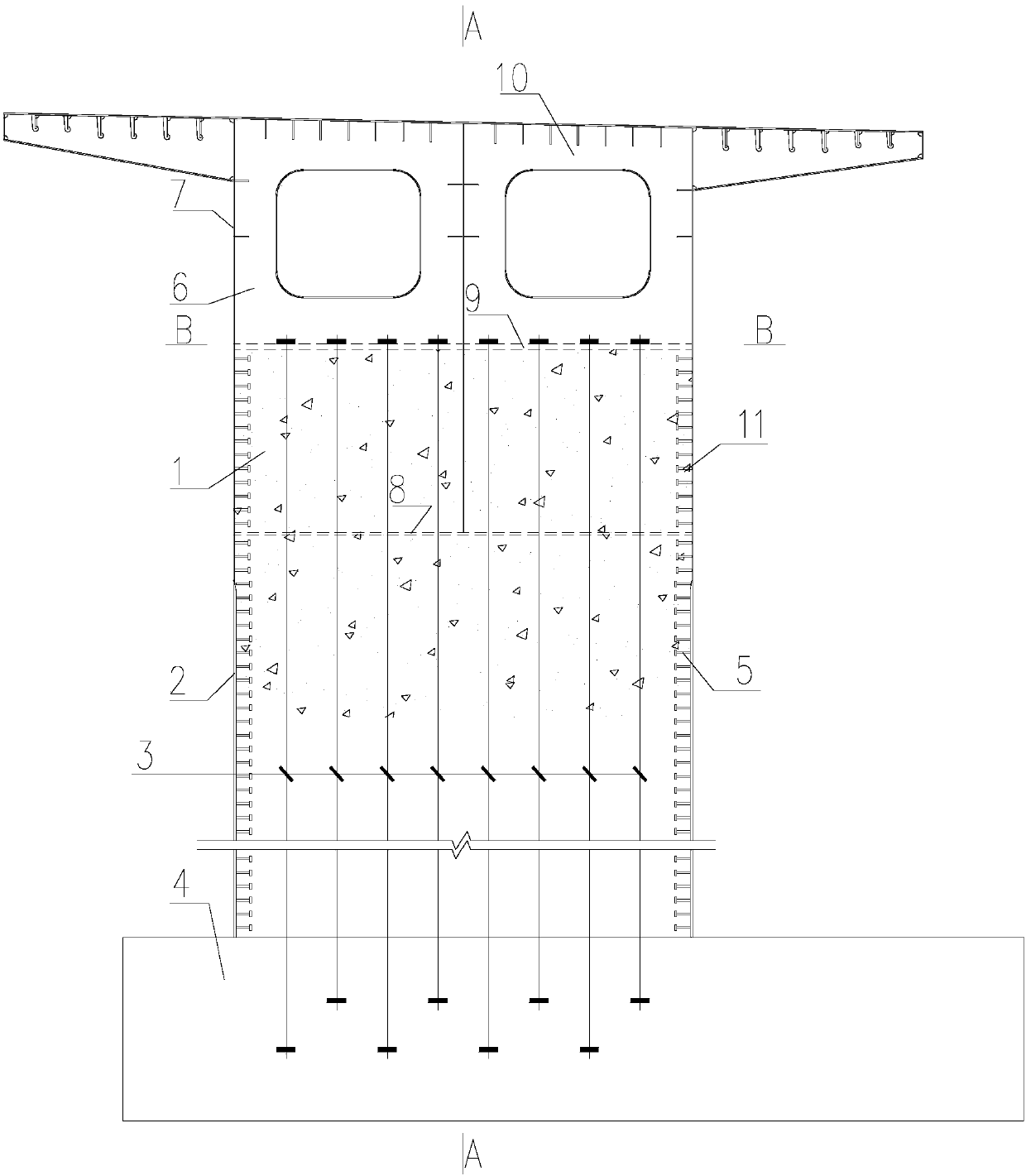

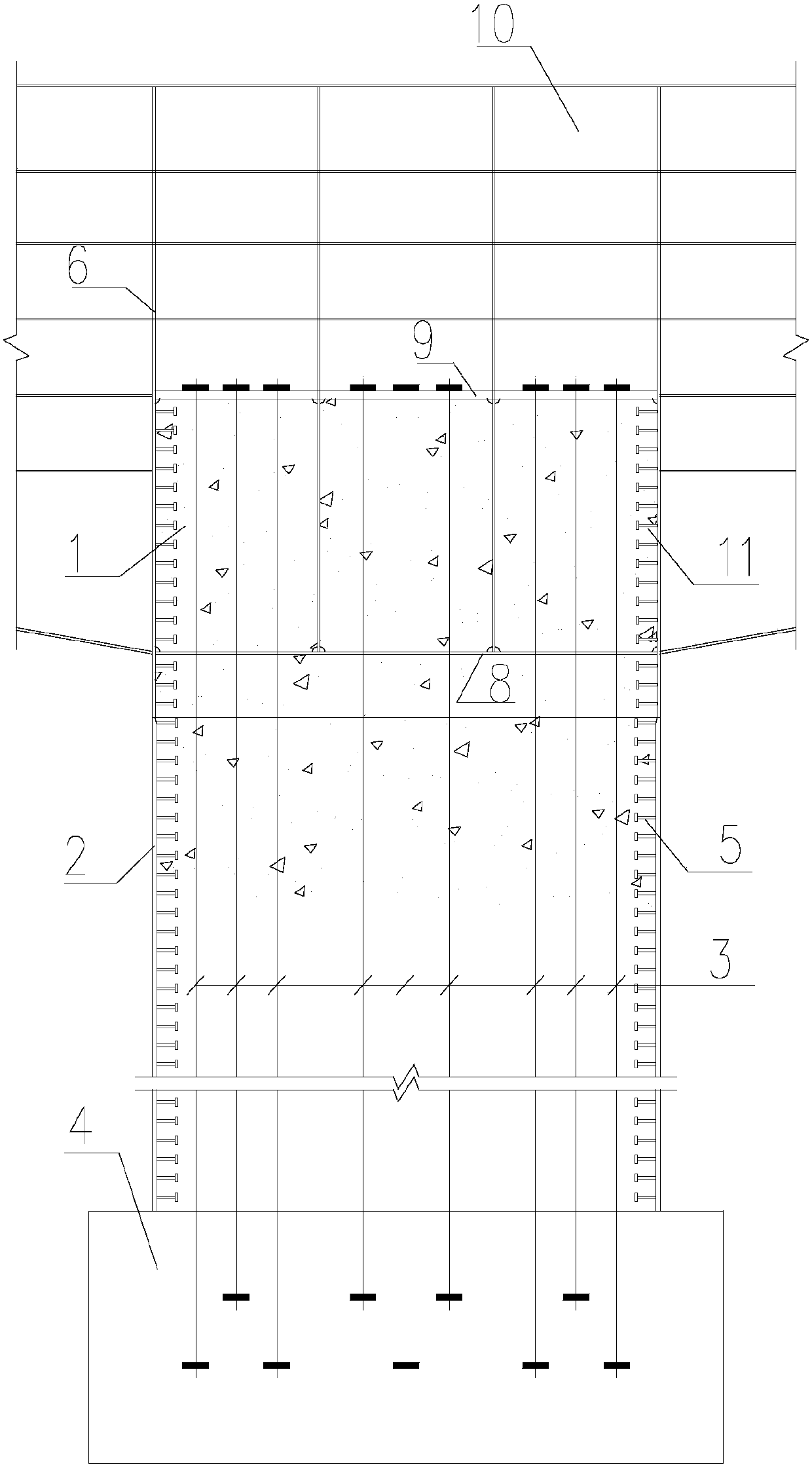

[0016] see Figure 1 ~ Figure 3 , a construction method for consolidating a steel box girder of a swivel rigid frame bridge with a concrete pier, using the following steps:

[0017] 1) When constructing the upper turntable 4 or the concrete pier, a plurality of prestressed steel rods 3 vertically arranged are pre-buried, and when the concrete pier is constructed, an outsourcing force-transmitting steel plate 2 is arranged on the outer surface thereof, and the The inner side of the outsourcing force transmission steel plate 2 is fixedly connected with a shear nail II5 perpendicular to it, and a pier top post-casting section is reserved on the top of the outsourcing force transmission steel plate 2 . For the convenience of construction, when p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com