One-component room temperature vulcanized conductive silica gel and preparation method thereof

A technology of conductive silica gel and room temperature vulcanization, which is applied in the direction of conductive adhesives, adhesives, non-polymer adhesive additives, etc., to achieve the effects of good adhesion, simple operation, and slow viscosity change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

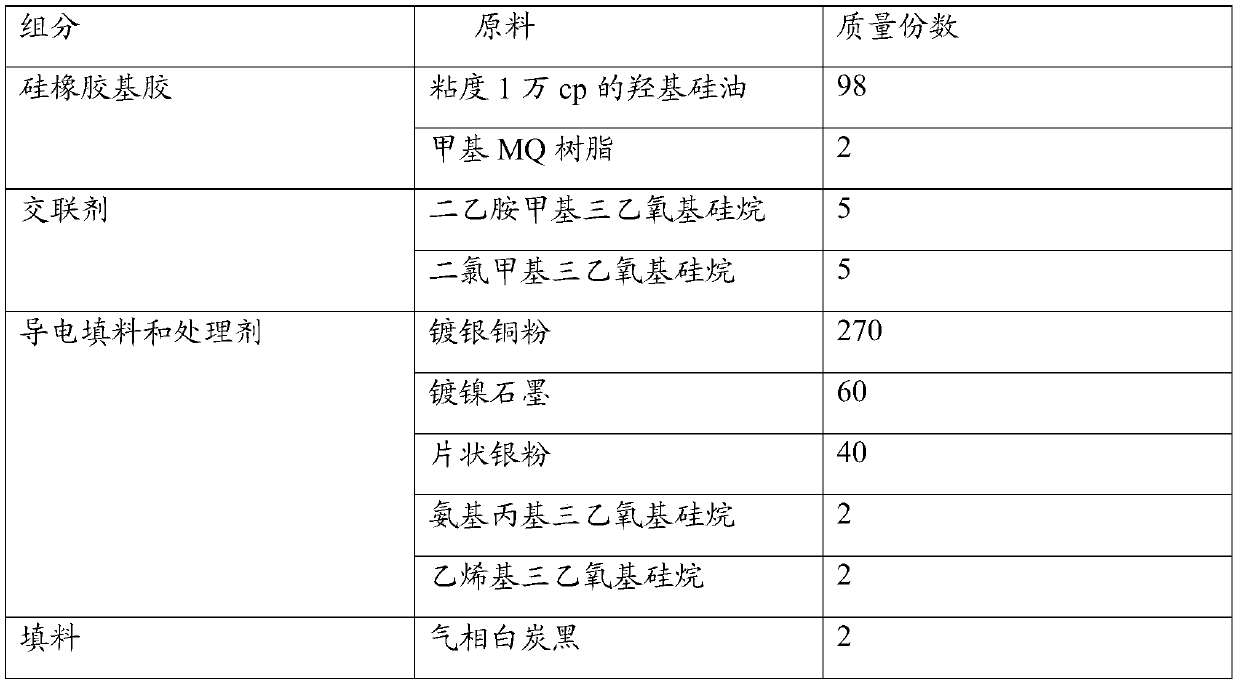

Embodiment 1

[0029]

[0030] The preparation method of one-component RTV conductive silica gel of the present invention, the steps are as follows:

[0031] Step 1: Preparation of conductive filler and treatment agent

[0032] Put the conductive filler on a metal or ceramic plate, and bake it in an oven at 50°C for 1 hour to remove the moisture absorbed in the conductive filler; put the conductive filler and treatment agent into a planetary mixer according to the ratio of conductive silica gel, and disperse Stir for 30 minutes at a stirring speed of 100 rpm to prepare the conductive filler and treatment agent.

[0033] Step 2: Preparation of conductive silicone material

[0034] Weigh various raw materials according to the ratio of the conductive silica gel, first put the hydroxyl silicone oil, MQ resin, conductive filler and treatment agent, and filler into a planetary mixer, stir for 1 hour, disperse at a speed of 500 rpm, and vacuum degree -0.1 MPa, material temperature 30°C. After...

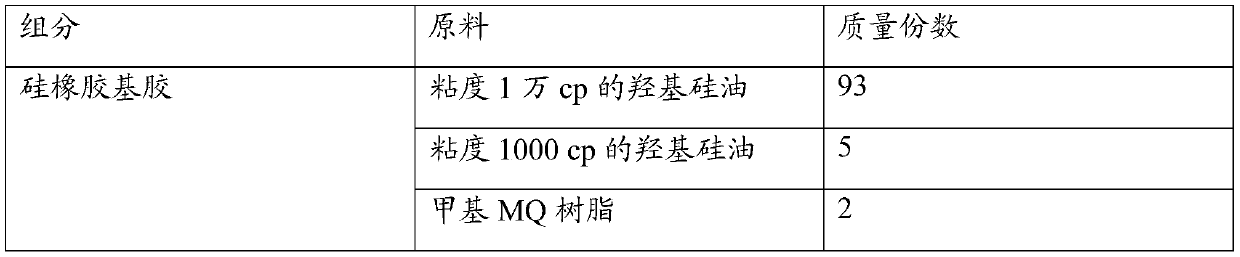

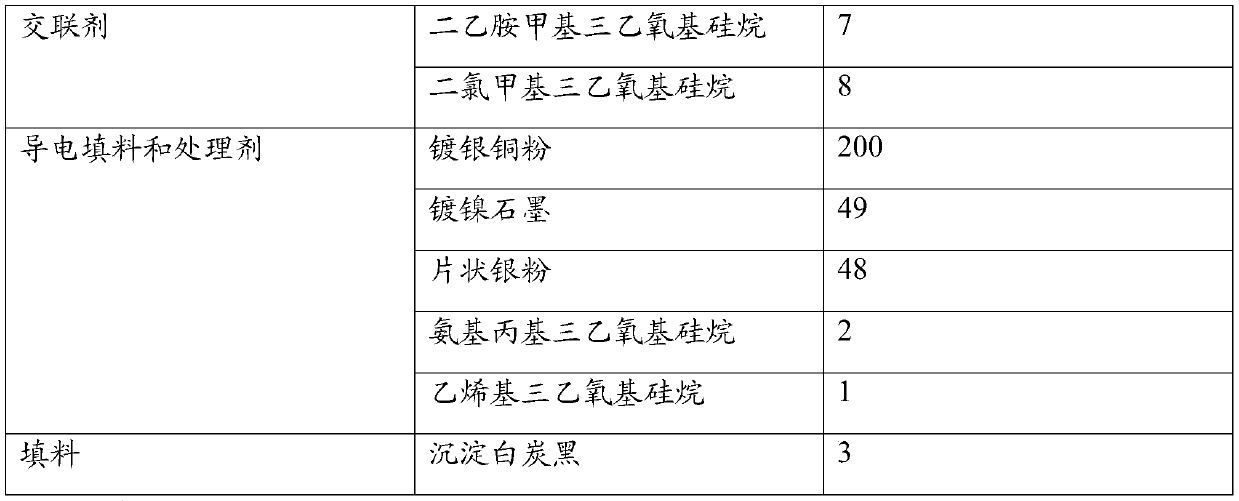

Embodiment 2

[0036]

[0037]

[0038] Preparation steps:

[0039] (1) Preparation of conductive filler and treatment agent

[0040] Put the conductive filler on a metal or ceramic plate, and bake it in an oven at 50°C for 2 hours to remove the moisture absorbed in the conductive filler; put the conductive filler and treatment agent into a planetary mixer according to the ratio of conductive silica gel, and disperse Stir for 20 minutes at a stirring speed of 70 rpm to prepare the conductive filler and treatment agent.

[0041] (2) Preparation of conductive silicone material

[0042] Weigh various raw materials according to the ratio of the conductive silica gel, first put the two kinds of hydroxyl silicone oils with different viscosities, MQ resin, conductive filler and treatment agent, and filler into the planetary mixer, stir for 1.5h, and disperse at a speed of 1250rpm, vacuum degree -0.1MPa, material temperature 15°C. After stirring evenly, add the cross-linking agent, and then...

Embodiment 3

[0044]

[0045]

[0046] Preparation method:

[0047] (1) Preparation of conductive filler and treatment agent

[0048] Put the conductive filler on a metal or ceramic plate, and bake it in an oven at 50°C for 3 hours to remove the moisture absorbed in the conductive filler; put the conductive filler and treatment agent into a planetary mixer according to the ratio of conductive silica gel, and disperse Stir for 10 minutes at a stirring speed of 40 rpm to prepare the conductive filler and treatment agent.

[0049] (2) Preparation of conductive silicone material

[0050]Weigh various raw materials according to the ratio of the conductive silica gel, first put the two kinds of hydroxyl silicone oils with different viscosities, MQ resin, conductive filler and treatment agent, and filler into the planetary mixer, stir for 2 hours, and disperse at a speed of 2000rpm , vacuum degree -0.1MPa, material temperature 10°C, after stirring evenly, add the crosslinking agent, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com