A kind of synthetic method of n-benzyl-4-methylpiperidin-3-one hydrochloride

The technology of a methylpiperidine and a synthesis method is applied in the synthesis field of N-benzyl-4-methylpiperidin-3-one hydrochloride, can solve the problem of high production cost, and achieves good product quality and novel process , the effect of short synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

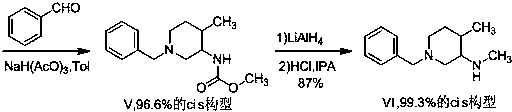

[0036] (1) 96.5 g (0.5 mol) of N-benzylglycine ethyl ester and 123.5 g (0.75 mol) of ethyl 2-methyl-4-chlorobutyrate were added to a 2000 mL reaction flask, and 650 mL of carbon tetrachloride was added. and 76 g (0.75 mol) of triethylamine, heated to reflux, and reacted for 18 h. After detection of the completion of the reaction, the reaction solution was cooled to 22 °C, filtered, and the filtrate was concentrated under reduced pressure to obtain 165 g of intermediate XVIII as a brown oil. The purity detected by HPLC was 94.1%. , directly into the next reaction.

[0037] (2) Add 165 g of the concentrated intermediate XVIII prepared in the previous step to a 2000 mL reaction flask, add 850 mL of toluene to dissolve, add 96.1 g (1.0 mol) of sodium tert-butoxide, heat under reflux, and react for 5 hours. HPLC detects that the reaction of the raw materials is basically complete. , the reaction solution was cooled to room temperature, 55 g of acetic acid was added dropwise, the pH...

Embodiment 2

[0040] (1) 96.5g (0.5mol) of N-benzylglycine ethyl ester and 136g (0.65mol) of ethyl 2-methyl-4-bromobutanoate were added to a 2000mL reaction flask, 850mL of tetrahydrofuran and 69g of sodium carbonate were added (0.65 mol), heated to reflux, and reacted for 22 h. After detection of the completion of the reaction, the reaction solution was cooled to 22 °C, filtered, and the filtrate was concentrated under reduced pressure to obtain 164.6 g of a brown oily intermediate XVIII. The purity detected by HPLC was 94.8%. one-step reaction.

[0041] (2) Add 164.6g of brown oil prepared in the previous step into a 2000mL reaction flask, add 850ml of xylene, add 90.0g (0.8mol) of potassium tert-butoxide, heat to reflux, react for 4.5h, and HPLC detects that the reaction of the raw materials is basically complete After that, the reaction solution was cooled to room temperature, 44 g of acetic acid was added dropwise, the pH was adjusted to 6-8, 280 mL of saturated brine was added, the la...

Embodiment 3

[0044] (1) 96.5g (0.5mol) of N-benzylglycine ethyl ester and 136g (0.65mol) of ethyl 2-methyl-4-bromobutanoate were added to a 2000mL reaction flask, and 750mL of toluene and N,N - Diisopropylethylamine 76g (0.75 mol), heated to reflux, and reacted for 8 hours. After the reaction was detected, the reaction solution was cooled to 24°C, filtered, and the filtrate was detected by HPLC to have a purity of 93.3%. The filtrate was directly put into the next reaction.

[0045] (2) Add the toluene filtrate prepared in the previous step into a 2000mL reaction flask, add 65.0g (0.95mol) of sodium ethoxide, heat under reflux, and react for 6.5h. After HPLC detects that the reaction of the raw materials is basically complete, the reaction solution is cooled to room temperature, and the 55 g of acetic acid, adjusted to pH 6-8, added with 400 mL of tap water, stirred for layers, transferred to a separatory funnel, the organic layer was washed with saturated brine 300 mL × 2, then dried by ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com