A method for preparing porous ceramics by low-temperature sintering

A porous ceramic and low-temperature sintering technology, which is applied in the field of porous ceramics, can solve the problems of insufficient ceramic strength, decreased pore permeability, and increased fluid flow friction resistance, etc., and achieves the effects of easy industrialization, high ceramic strength, and strong attraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

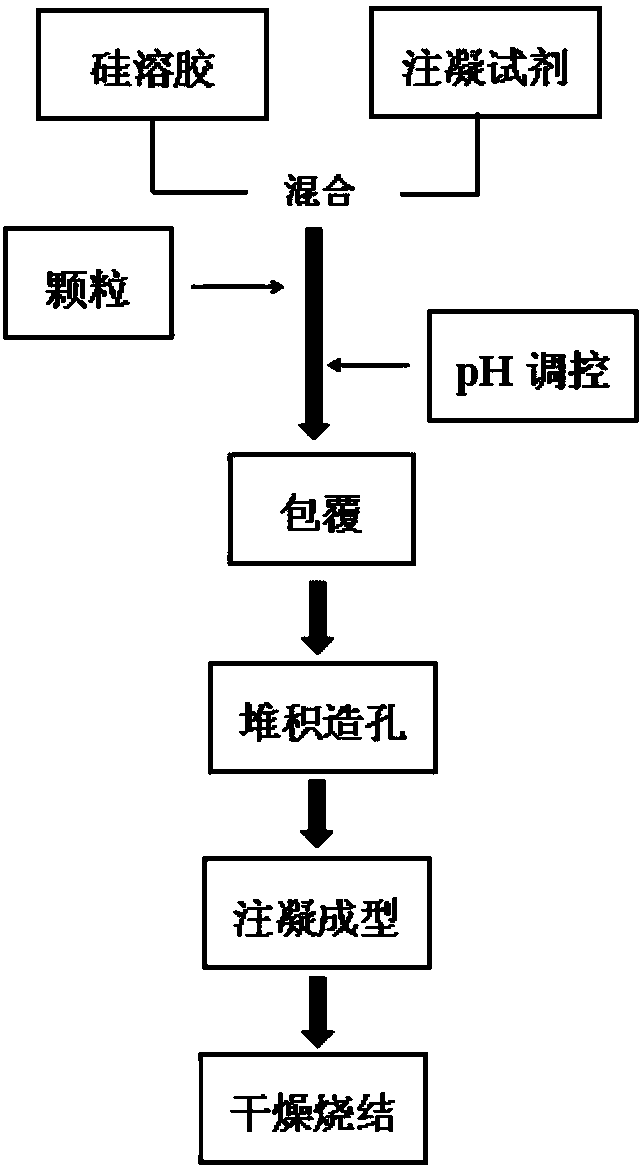

[0027] The preparation process of the present invention will be further described below in conjunction with the accompanying drawings.

[0028] The flow chart of the preparation of porous ceramics by coating-injection molding is attached figure 1 Shown:

[0029] (1) Dissolving the injection gel forming reagent in a silica sol solution with a concentration of 5-20wt.%, wherein the concentration of the organic monomer in the liquid phase is 2-20wt.%, and the mass ratio of MBAM to the organic monomer is 1: 30-1:10, (NH 4 ) 2 S 2 o 4 Occupying 3-10% of the mass fraction of organic monomers, TEMED and (NH 4 ) 2 S 2 o 4 The mass ratio is 1:1-1:6.

[0030] (2) Then the ceramic powder is mixed with the liquid phase premix, the volume fraction of the powder is 50 vol%, and the particles are uniformly dispersed by mechanical stirring. During the stirring process, the pH of the solution was adjusted to a set value, and then the stirring was continued for 10 min to complete the ...

Embodiment 1

[0036]In the silica sol solution with a concentration of 5wt.%, add the injection molding reagent, the reagent composition is 2wt.% of organic monomer, the mass ratio of MBAM to organic monomer is 1:30, (NH 4 ) 2 S 2 o 4 Occupying 3% of the mass fraction of organic monomers, (NH 4 ) 2 S 2 o 4 The mass ratio to TEMED polyol is 1:1, and the mixed solution is prepared. Add the alumina powder into the premix, stir to disperse and adjust the pH of the slurry to 3 to complete the coating process. After the slurry was injected into the mold, the particles were piled up to make holes, and then placed at 80° C., and the polymerization reaction time was 10 minutes. After the green body is dried, it is sintered at 1300° C. for 2 hours to obtain a porous ceramic with a porosity of 40% and a strength of 30 MPa.

Embodiment 2

[0038] In the silica sol solution with a concentration of 15wt.%, add the injection molding reagent, the reagent composition is organic monomer 10wt.%, the mass ratio of MBAM to organic monomer is 1:20, (NH 4 ) 2 S 2 o 4 Occupying 7% of the mass fraction of organic monomers, (NH 4 ) 2 S 2 o 4 The mass ratio of TEMED polyol to TEMED polyol is 1:3, and the mixed liquid is prepared. Add the alumina powder into the premix, stir to disperse and adjust the pH of the slurry to 3 to complete the coating process. After the slurry was injected into the mold, the particles were piled up to make holes, and then placed at 50° C., and the polymerization reaction time was 40 minutes. After the green body is dried, it is sintered at 1300°C for 2 hours to obtain a porous ceramic with a porosity of 39% and a strength of 35MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com